Among the abundance of building material it is difficult to quickly select the ideal one, having weighed all the pros and cons of any of them. Technologies are developing so quickly that building materials, which today were the pinnacle of perfection, will become obsolete tomorrow. Until recently, the builder had to perform a certain sequence of actions. After the walls were laid, the warming was carried out, and then the decoration was done. Finishing the facade of the house with thermopanels allows you to save time and perform two operations in one pass. In addition, the appearance will not be realized by reducing heat loss. Whether the game is worth the candle will allow to find out the material of this article.

What kind of material is

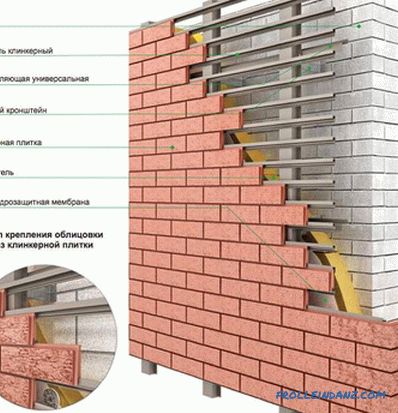

Thermal Panel Device

Thermal Panel Device

The name makes it clear that the main emphasis is placed not only on the appearance, but also on the provision of thermal insulation of the treated surface. This is achieved at the expense of the material used. Foamed polystyrene foam or polyurethane can act as a sealing layer. The second in its quality and strength characteristics ahead of the foam. But it is worth considering that the cost of such a product will be somewhat higher.

The thickness of the layer is selected so that the dew point is shifted approximately in the middle line of the insulation. Thus, the question of the emergence and development of mold is solved, and the service life of the finish is significantly extended. The organization of ventilation gaps is not required. In addition, diffusion processes proceed freely. The substrate for the panels in some types is a moisture-resistant OSB sheet. It acts as a stabilizer and a basis for the whole structure. It is also quite simple to process and fix it on a concrete or brick plane.

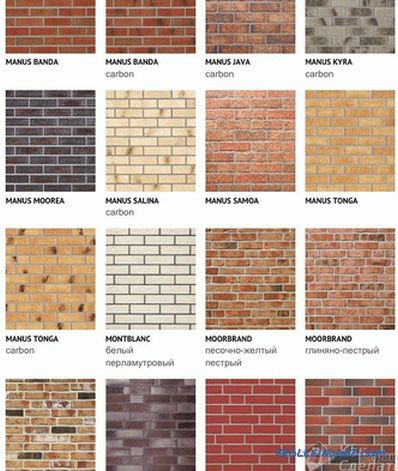

A variety of decor

A variety of decor

A pleasant appearance is ensured by a beautiful lining. Its color can be chosen according to the wishes or instructions of the customer. The decorative layer is resistant to physical stress, so it is difficult to damage. It is made by the method of single or multiple firing. Pigments and additives have already been added to the mixture. Because of this, it is simply impossible to wash the color with rainwater or other effects. The front part is molded by pressing or extrusion, so by its appearance the plane can be not only smooth, but also with a certain pattern, which, for example, imitates natural stone.

Thermopanels for stone

Thermopanels for stone

Some types of construction also include a foil layer. Its main task is to provide a vapor barrier, as well as a reflection of the heat that is directed from the room to the street.

The key point that facilitates installation is the locking mechanism. He is so well thought out, verified and fitted that everything is going as a designer. Separate elements go not just end to end, but fasten with a small overlap (if a thorn-groove connection is provided). With this approach, it is possible to eliminate cold bridges, which inevitably arise in the first version. Even oblique rain is not able to force water to leak into the middle.

Do not worry that some investments will be required at this stage. The fact is that heat losses during the heating season can be reduced almost by half, and this will affect the amount of bills. In addition, in the summer, insulation works on the principle of a thermos. If you run cool air in the evening, it will last for almost the entire day. This means that it will be necessary to turn on the air conditioner much less frequently. Payback does not take long.

Varieties and advantages

The user is not limited in the choice of available subspecies. In addition to the insulating layer, the differences relate to the lining used.

Glazed ceramics . It is a continuation of fashion, which dates back to the second half of the XX century, when houses and other buildings began to be tiled. The advantages of this solution is a smooth surface that has a glossy finish. In addition, it is very easy to clean, so if the building is close to the road, it can always be washed under the pressure of water from a hose. Service life is very long and with proper care can reach more than 50 years.

Porcelain

Porcelain

Porcelain Tile . According to its characteristics, it is many times greater than the usual ceramic. This is due to the method of its manufacture. Although the constituent materials are all the same components (feldspar, clay, kaolin, quartz sand), they burn it at a temperature of up to 1300 ° C. At the same time, it is exposed to a press of up to 500 kg. This approach makes it possible to carry out the process of diffusion so much that the powders fuse together. All voids are eliminated and a quality monolith is obtained. Because of this, moisture is simply not able to seep inside.And this means that even in the winter time the tile will not burst when the temperature drops. The strength is so high that it surpasses some types of natural stone in performance.

In appearance, it is not necessarily made in the form of facing bricks. It can be much larger, which simplifies the installation of such panels. Care is almost not required. Even ultraviolet will not interfere, so the tile on the sunny side will not differ shade. A large number of different variations of colors and shapes are available for selection.

Thermal panels with clinker tiles

Thermal panels with clinker tiles

Clinker tiles . According to its characteristics it is in many ways similar to the previous one. It is absolutely eco-friendly, because it is made from natural clay. Do not apply any artificial chemical impurities or additives. It was originally used not only for building houses, but also for paving roads. This suggests that it has sufficient strength and resistance to high weight. The production method includes single firing at high temperatures. Quartz, which is part of it, melts and closes all the pores through which water could leak. The surface is very smooth.

The product imitates a facing brick so well that it is quite difficult for an ordinary person to distinguish it. Scratch resistance is a huge plus. Do not have to fear that, hitting the surface with any object, you can harm it. Tiles of this kind withstand more than 300 cycles of complete freezing and thawing. This indicator is very important for those regions where in winter the temperature can reach large negative values. In addition, clinker is an additional layer of noise insulation, plus insulation.

Iso-siding

Iso-siding

In addition to the facing material, the substrate used can be different, as well as insulation.

Highlight:

- Metallic. They are a sheath made of sheet material, it can be aluminum or galvanized sheet, inside of which there is a mineral wool or polymers insulation. Appearance may resemble brickwork, tile or other options.

- Isosiding. In appearance, it may resemble a block house, wooden paneling or ordinary siding. The difference lies in the fact that the individual elements are made with internal cavities, which are filled with foamed polyurethane.

- Heat siding. Simply put, these are all the same sheets of polystyrene foam or polyurethane foam. But the front side of the material is made with an imitation of a pattern and reinforced with stone chips, which prevents damage from touch and impact.

Heat siding

Heat siding

Summing up, you can highlight the positive aspects of using thermal panels when performing insulation and heat insulation works:

- high speed of work performed;

- pleasant appearance;

- no need for finishing painting or other finishing;

- resistance to impact ultraviolet light;

- low weight of a single element;

- used where it is not possible to use facing brick;

- long service life;

- excellent waterproofing properties;

- a large number of freeze / thaw cycles;

- ease of care;

- resistance to the formation of fungus;

- resistance to physical effects;

- ability to compensate for irregularities surface;

- environmental friendliness of some species.

Facade trimmed with thermopanels

Facade trimmed with thermopanels

Of the inherent flaws are the following:

- some materials brittleness;

- relatively high price;

- a certain limitation in choice.

As you can see, there are very few minuses. The panels have occupied their niche and the direction continues to evolve towards the improvement of the components and the final result.

How to choose

Thermal Panel Textures

Thermal Panel Textures

Among the described abundance it is easy to get lost. But there are basic nuances that will allow you to choose the option that would be ideal for a particular project.

First of all, you need to decide on the type of panels you would like to see on the facade of your own house. This includes the type of substrate, the option of insulation, as well as lining material.

- Texture and shape. Perhaps the choice will be stopped on the classic version, which simulates a brick. But in most cases the house will simply merge with a mass of the same ones that are close by. If you want to realize your individuality, you can stay on the shape of a natural stone, intricate patterns or mosaic. Everything will depend on what products the manufacturer can offer.

- Color. It is important to take into account the general idea of the exterior.If you want to organize an atmosphere that will contribute to rest, it is better to stop at neutral colors. Such differs a brick tile or porcelain tile. It will emphasize the solidity and high cost of decoration. Lining of glazed products or blanks for independent painting will allow to escape from everyday dullness and boredom.

- Insulation thickness. This factor plays a very important role. Everything will depend on how harsh the climate in a particular region. Then the rule is, the thicker the better. In a situation when the desired texture does not have the required insulator layer, then additional modules of foam plastic or mineral wool are separately mounted on the wall.

- Manufacturer. Not the last nuance that is worth considering. The fact is that a self-respecting company provides an official guarantee, subject to compliance with all the required installation technologies. Plates that are made in the artisanal way may last for several years, after which they will require extensive repair or complete replacement. In such cases, it is better, as they say, to overpay for the brand, than to buy a whole new batch.

- Budget. Everything can be limited by the amount that is planned for purchase. But do not approach the issue from the point of view, the cheaper it is, the faster it is acquired and installed. Better some time to dig into the middle version. He usually combines quality and beauty. All that relates to the elite subspecies created to underline the status.

In appearance, select what you personally like. After all, you'll be looking at the end result every day.

Self-fabricated

If you set a goal, you can make your own thermal panels. This is relevant in the case when all the options were considered, but none of the proposed options came up. For the whole process, we need the following components:

- polyurethane foam (it is better to use the Titan brand);

- the tile you like for outdoor decoration or stone;

- sheets of foam plastic or polyurethane foam ;

- a device that can act as a press;

- a tape measure;

- a handsaw or a special cutter for polymers.

Titan Foam

Titan Foam

First of all, you need to build a press. Its dimensions should be such that one or more sheets of insulation can be freely placed in it. In its role can act a workbench or table. Further follows:

- Align the plane well. You can use for this purpose the usual construction level. The surface itself should also be flat. To do this, take the OSB, particleboard or metal sheet.

- The same size requires another element that will serve as a clamp. To make it harder, metal weights are evenly attached to it. Another way would be the construction of a metal frame. For this you need a rectangular or square shaped tube. According to the size of the top sheet, a figure with jumpers is made. On its big sides loops are made under the studs. Just below them, the hinges are welded to the table.

- The material to be used as the base is laid on the work surface. This may be, for example, moisture resistant OSB stove. But its lateral ends should be cut in advance in the form of a lock for binding. Its configuration will depend on the selected lining.

- The base is coated with an adhesive.

- Above are placed sheets of insulation.

- Covers the entire structure of the prepared part with loops.

- The holes are aligned, studs are inserted into them and clamped.

- The holding time is equal to the hardening time of the glue; it is usually indicated on the package.

- After that, it is necessary to trim the foam according to the format of the cut ends.

- The next stage is the installation of blanks under fasteners. Conventional umbrellas are perfect for this purpose. They must be placed in several rows so that later the hole falls into the seam between the tiles. Under the cap is made a small recess. Then they will lie flush. The protruding end is clipped.

- The tile or stone is fixed in the same way as the factory panels, but the pressing force will be less than in the first case. This is necessary in order not to damage the lining and not to push through the foam.

In the case of this approach, it will be possible to partially save on the total final amount, as well as create a unique design. The strength of the products is high. The fact is that the glue penetrates into the insulator to a depth of almost 1 cm, so it can only be torn off with a part of the foam. In addition, to repair homemade slabs at times easier than the factory. Among the shortcomings can highlight the need for a large amount of time that will go on preparation.

Installation process

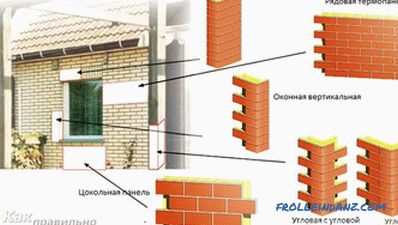

Installation of the thermopanels

Installation of the thermopanels

The installation process will not cause difficulties even beginners in the construction business. For successful completion of all stages, it is important to have minimal skills in working with punch and level. In total, there are two ways in which installation can be carried out:

- Directly to the wall plane. This option is most easily implemented in the case when the surface is extruded in compliance with the vertical plane. It may already be plastered, with certain shortcomings being eliminated.

- With the use of metal or wooden crates. It will be a salvation in a situation where significant errors were made at the stage of construction, and they must be hidden. Costs in this situation increase slightly. First, you will need funds for strips under the frame. Secondly, the space between the wall and the panels cannot be left empty. If this is done, then the effect of them will be only visual. Gaps will need to close another layer of insulator.

Installing the thermopanel to the crate

Installing the thermopanel to the crate

To solve the first problem, you need these tools:

- punch;

- level;

- tape measure;

- screws and dowels (length depends on the panel thickness);

- joint filler ;

- jointing tool;

- grouting gun;

- metal profile;

- screwdriver;

- hacksaw or grinder with a nozzle concrete;

- assembly glue.

Directly to the wall

Directly to the wall

The whole process begins with the insulation of the basement. If left without isolation, then the entire wall will freeze because of the cold bridge.

- The metal profile UD for drywall is mounted. Every 50 cm it should be fixed with a dowel and screw. It will be located at a height of 5 cm from the surface of the blind area. The gap is made in order to leave space to compensate for thermal expansion. It is necessary to set it in level. Also, it should not be close to the wall. A distance of 0.5‒1 cm is observed. For this, linings are made of insulation or polyethylene, but not wood.

- The space between the profile and the wall is filled with polyurethane foam. This is done in order to eliminate the possibility of air circulation between the plane and the panels.

- Before mounting the first element, the profile cavity is filled with foam.

- For greater convenience, the laying of cladding is better to start from the left corner of the building.

- You can arrange individual sheets in a staggered order or in horizontal rows.

- Each element is level by level before fixing. If the wall is uneven, then under it you can make the lining of dense polyurethane foam.

- A layer of foam is applied to the vertical and horizontal joint. There is no need to cover the entire back side with an adhesive. At expansion it will lead to a structure deformation.

- A wall is drilled through the factory holes with a perforator. The depth should be 3 cm larger than the dowel.

- A small amount of foam is fed into the hole. After that, the dowel is inserted and the screw is screwed. The latter should be slightly drowned. A small amount of polyurethane foam is added to the gap again. This is done to eliminate the cold bridge, which can be formed through metal fasteners.

- To ensure a good junction at the corners, it will be necessary to cut the ends of two abutting panels at 45 °. In addition, in the resulting plane, it is also necessary to cut a chute, which will subsequently be sealed.

- The slopes of windows and doors are decorated with special polyurethane overlays.

- The final step is to grout the joints. The most convenient way to do this is to use a sealant gun. His nose is cut off at an angle of 45 °. It is filled with grout and it is evenly distributed throughout the plane so as to fill the space between the tiles. After a few minutes, you can go through the jointing tool, while removing the excess solution.

Additional elements

Additional elements

Installation with the installation of the frame has many common points, but there are also its nuances. Tools will need the same as in the previous case.

- All walls are vapor-insulated. This is done to prevent possible accumulation of moisture and the formation of fungus and mold.

- The distribution in the wall plane is checked. To accomplish this task, you can use a plumb line or laser level. In the first case, you will need to screw the screw into the upper part and tie a thread to it. After that, it is measured from it to the wall along its entire length. Relevant notes are made.A laser plotter of planes does it this way: a beam is projected parallel to the wall and the distance from it is checked with a tape measure.

- Suspensions are mounted in 40 cm steps. Already they screwed metal straps. At the same time, the distance from the plane is observed according to the marked marks. At the corners should be two elements. One is designed directly for fixing the panel, and the second for the corner element.

- To stiffen, perpendicular jumpers are mounted at the top and bottom.

- A heater is placed in the cavities formed. You can use mineral wool or foamed polymer. It is fixed to the wall with umbrellas. In the second case, the seams are filled with foam to eliminate the cold bridges.

- Installation of the main panels is made from the left corner, as in the previous case.

- They are fastened directly to the mounted frame. The screw at the same time must pass through the insulation and rest against a wooden backing.

- Joints between parts are coated with polyurethane foam. This serves as both an additional fixative and an insulator.

- The corner elements are last sewn. Thus it is possible to eliminate as much as possible the breakdowns that occurred during the docking.

- Special slopes are provided for windows and doors, which are trimmed to fit and assembled. It should be remembered that the junction to the main elements are foamed.

Mounting on a metal frame

Mounting on a metal frame

Try experimenting a little by adding a certain highlight to the overall exterior. For example, one lane in the middle of the wall can be decorated with basement panels. It always looks very impressive. Keeping in mind the basic principles that are applied to thermal insulation of the facade with thermopanels, one can achieve the desired result.

Video

The video shows the installation of thermopaels thermoparks with clinker tiles:

A below - the installation of Termosit thermopanels:

Read also:

- How to finish the facade with siding.

- How to decorate the facade with a planken.

- How to decorate the basement of the house.

- How to paint the facade.

- Installation of metal cassettes on the facade.