When choosing a modern variant of finishing the facade of a new building or reconstruction of an old one, it is worth considering metal cassettes. This type of decoration protects the walls from moisture, and due to the variety of colors it makes the exterior of the house elegant and attractive. Facing the facade with metal cassettes takes place in a short time, the ease of installation allows you to start work without professional building skills.

What is a front cassette

Front cassettes

Front cassettes

Metal tapes are made of galvanized sheets steel, aluminum, brass or copper. The thickness of the blanks is from 0.7 to 1.5 mm. The side edges of the sheet are bent and a structure is formed to create ventilated facades. The shape of the cassette can be rectangular, square, trapezoidal. The outer surface of the material is covered with powder paint or polymer film. Sheets of steel are heavy, so for the manufacture of cassettes using metal no thicker than 1.2 mm, aluminum panels to create a rigid structure must be 2 mm thick.

The merits of metal cassettes

Such an object looks presentable

Such an object looks presentable

- Presentable external the view creates an individual building style.

- Installation accessibility and quick installation due to the large dimensions of the individual panels.

- Leveling the surface and hiding all wall defects.

- Durability guaranteed by material resistance to precipitation.

- The surface retains its color for a long time, does not fade under the sun.

- The material is resistant to high and low temperature.

- Fire safety of the building is ensured.

There are few drawbacks in such a lining, these include: high cost and considerable weight of the cladding of the facade. Steel cassettes are used for new buildings that have a solid foundation, they are not used for restoration. Aluminum panels are light, attractive look and durability, only the high cost of the material prevents its widespread use. Excellent performance and impeccable quality cassettes commensurate with their price.

Fastening methods

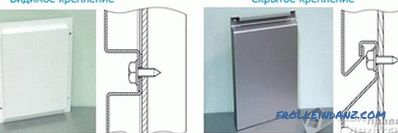

The facade of metal cassettes is finished in two ways:

Open fastening

Open fastening

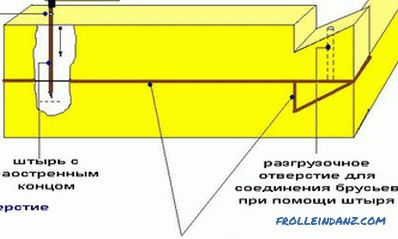

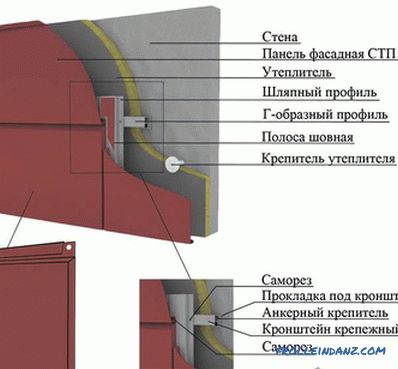

- Open fasteners. Front cassettes made under visible fasteners have bent edges, which are perforated. Each panel is mounted separately with screws. The cassettes are overlapped and fastened to the vertical uprights of the frame. This option facilitates future repairs.

- Hidden fasteners. The method is used for thin panels, their upper part is screwed to the crate with self-tapping screws, and the lower edge of each cassette is snapped into the panel in the bottom row. These panels have only one limb located at the top. The edge formed by it becomes a place for fixing the edge of the adjacent tile. In the first row of the cassette are attached to the initial rail, and then to each other. The junction is invisible. To disassemble such a structure is difficult, but it looks attractive on the facade of the building.

Closed fixing

Closed fixing

The choice of fixing method is influenced by the shape of the panels, their weight and architectural features of the facade.

Assembly steps

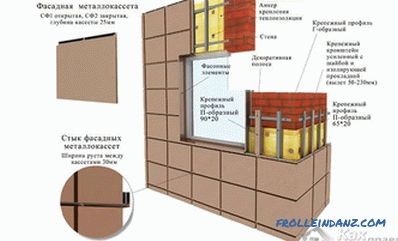

To create a ventilated facade, you need to install a frame that is attached to the building with anchors and brackets. To install it, proceed after checking the walls for the intended load. It is produced by experiment: two dowels are hammered, on which a fragment of the batten is fixed with a load.

Components

Components

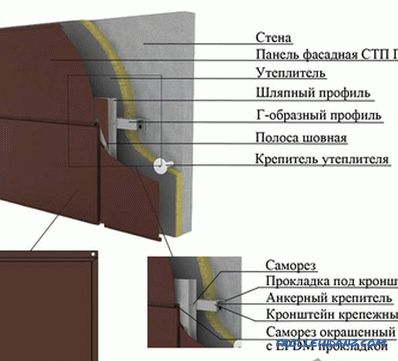

- The first thing they do at the start of the installation is the marking of the walls under the brackets for crates. For data accuracy, use a laser or water level. The marking starts from the bottom of the building, it must provide a strictly vertical plane of the frame. The spacing of the strips depends on the size of the metal cassettes: if the panels used are longer than 70 cm, additional brackets are installed. Holes for the anchor are drilled with a perforator. It is necessary to avoid driving the fastener into the connecting seams of the wall, as the brickwork is especially sensitive to destruction. A paronit gasket is placed between the bracket and the surface of the facade. The length of the anchor for a concrete wall is 8 cm, if the building is brick-built, you will need fasteners 10 cm long.

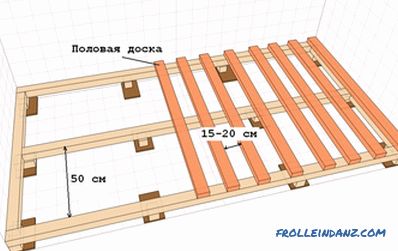

- The battens are fixed on the installed brackets, fixing is carried out with screws.

- Next, the insulation layer is laid. To preserve fire safety and reduce heat loss, non-combustible materials are used, these include mineral wool, extruded polystyrene foam. They are attached to the surface with special dowels with a round massive head, they will need 5 pieces per 1 m 2 .

- The layer of insulation is protected from the penetration of moisture and weathering with a special wind membrane, its parts are installed with an overlap and fixed with self-tapping screws. If necessary the waterproofing cloth keeps within.

- A main vertical crate is mounted from the hat profile, its height provides space for ventilation of the facade. For the installation of the first row at the bottom of the fixed profile and basement ebb.

- The installation of metal cassettes begins from the bottom, from the left corner of the building. Before installation, the protective film is removed from the side parts. The lower part of the front panels is latched onto the starting plate, the upper part is fastened with self-tapping screws. The installation of the following rows takes place on the same principle: the bottom clings to the adjacent panel, and the top is fixed with fasteners. The cassette is held on two screws fixed at the ends of the upper edge, if necessary, the fastening takes place at intermediate points.

With the open mounting method, installation of metal cassettes on the frame can be started from any side. Convenient curved shape of the panels and slots for screws allow you to quickly install the cladding.

Features of installation

Features of installation

Installation of front cassettes includes installation of additional accessories providing a presentable look of facing and moisture protection. These elements include:

- spurs,

- slopes;

- rims;

- external and internal corners;

- crutches .

Mounting scheme for metal cassettes

Mounting scheme for metal cassettes

Without installing these parts, the structure will have an unfinished look, and also the advantages of cassette cladding of the facade will be lost.

When choosing the thickness of panels for building decoration, be guided not only by the manufacturer's recommendations, it is important to take into account the wind speed and weather conditions of the region, mechanical loads on the facade. Under adverse conditions, use a material of greater thickness and make a strong crate. Installation of a ventilated facade of metal cassettes requires consideration of all technological features and installation of the batten without any distortions. Such cladding will protect the walls of the building from negative impact for many years, improve the appearance and insulation.

See also:

Do-it-yourself mounting of front thermopanels

Finishing the facade with planken

Facing the facade with natural stone

Finishing the facade with your own siding

Video

Features of editing can be viewed in the following video:

Photos

Example ventilated facade of metal cassettes

Example ventilated facade of metal cassettes

Bright facade thanks to metal cassettes

Bright facade thanks to metal cassettes

Flush-mounted metal cassette finishing

Flush-mounted metal cassette finishing

Facing an industrial building

Facing an industrial building

Metal tape ornament

Metal tape ornament

Facing office building

Facing office building

Facing the facade of the store

Facing the facade of the store

Creative finishing with metal cassettes

Creative finishing with metal cassettes