In the process of designing and constructing a residential building, the question of the configuration and construction of the roof necessarily arises. Not only the set of materials for its installation, but also the design of the load-bearing walls on which this roof rests depends on the construction of the roof. Therefore, the calculation of the roof structure is one of the most important when designing a house. Rafter structures, bearing the roof together with the crate, are the main subject of calculation.

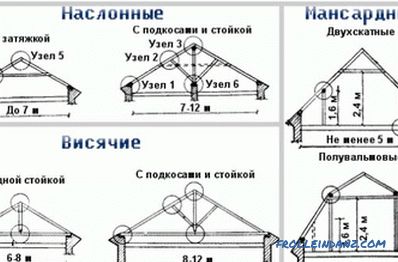

Types of roof truss systems.

It can be noted, historically, that the construction of roof rafters was wooden, all the terminology of modern constructions was borrowed from that time. Currently, in addition to wood, metal and reinforced concrete rafters are used, used to a greater extent in the construction of industrial buildings. In the low-rise housing construction, the main material remains lumber.

Rafter systems are divided into two groups:

- Suspended.

- Hanging.

When designing a roof, it is initially determined with the choice of rafter system: nylon or hanging.

Suspended and hanging types of truss systems

Suspended truss systems are used for buildings with additional rows of walls used as an additional support. Such buildings can measure up to 15-18 m with two additional supporting elements. The span between the supports should always be no more than 5–8 m. The rafter step is selected about 0.8–1.2 m, depending on the calculation. Part of the lower ends of the rafter legs rests on special rafter bars, mauerlaty.

Wiring plan for wall slings.

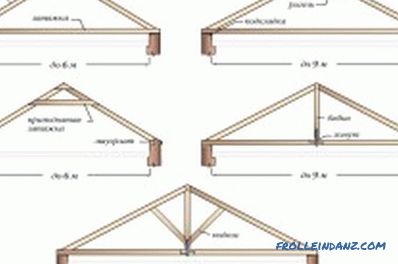

Between the uprights and the purlins, install struts that relieve the purlins and add rigidity to the structure. Struts are also used for unloading rafter legs, allowing to increase the overlapping width of the room. A truss leg that is longer than a standard sawn timber may be composite.

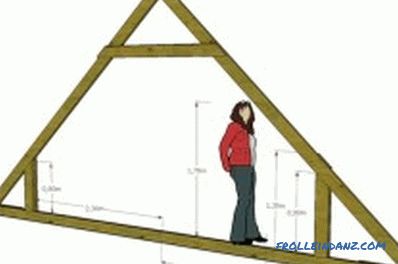

A hanging truss system differs from a canopy in that it relies only on its lower ends on supporting walls. Rafter legs of this design are loaded in two directions along and across the system. In addition, this design has a significant load, bursting the supporting walls. These loads are removed due to the puffs that connect the rafter legs. They can be both wooden and metal. Puffs are arranged horizontally and can settle at any height with the condition that the higher it is, the stronger it should be attached to the rafters.

The most elementary are gable roofs for small houses up to 6 m. For them there are many typical projects, and almost any edged lumber sold on the market can be used as a material. At their installation, slant rafters are used, the main element of which are inclined beams located along the roof slope. Elementally naslon rafter system consists of:

- rafter legs — the element on which the crate is mounted; 16> racks, strut, staggered, power plates used to strengthen the structure and more evenly distribute the load from the rafters on the girders and supporting structures.

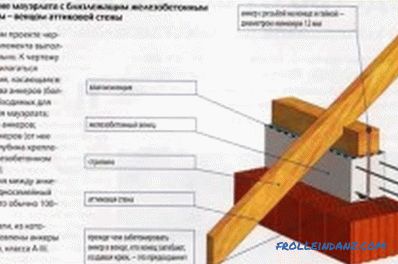

What is a mauerlat?

Types of hanging truss systems.

Mauerlaty, which is the support for rafter legs, can be located either the entire length of the supporting wall or be small, used for each individual rafter foot. In wooden houses, the upper log of the wall serves as the core. When laying brick walls, the mauerlat is laid flush with the brick from the outside and is isolated from the wall material.

Any roof is crowned with a ridge girder that connects the upper part of the rafters. He is the basis of the future skate.

The next design stage is the calculation of the cross section of the rafter legs and the pitch between them. Designing the construction of the rafters is an essential element not only because it is necessary to take into account the roof configuration scheme. During the entire service life of the roof is subjected to various loads, which can be divided into temporary and permanent. The latter are characterized by the weight of the roof and the structural elements themselves, while the temporary ones depend on the slope of the roof and the season. It can be both snow and wind.

The cross section of rafter legs is calculated on the basis of a minimum load of 200 kg / m, excluding the weight of the roof, insulation and insulating materials. A layer of snow can double this figure. When the slope of the roof is more than 60 °, the weight of the loads from the snow is not taken into account, since it is believed that with such a slope it does not linger.In order to increase the rigidity and carrying capacity of rafters, struts, racks and other elements are used, which allow to evenly distribute the load evenly throughout the whole structure.

Armature belt for the power plate.

To counteract the wind loads acting frontally, diagonal bracing is used.

The entire system must be protected from the possibility of its demolition by wind. To this end, during the construction of supporting walls, on their inner side, it is planned to install fasteners, to which parts of the truss structure are attracted by steel wire of at least 6 mm. Instead of embedded elements, you can use later steel studs.

Features of the design of roofs

Design should also include such details as the purpose of the attic. If it is used as an attic, it should not be overloaded with excess elements, and if it is not sewn from the inside, the requirements for the appearance of the rafter legs, which will serve as a decorative element of the room, will also change.

The type of roof and its slope determine the quality of the batten, the presence and design of the moisture insulation.

As mentioned earlier, the main material for low-rise construction for the manufacture of trusses are wood lumber. As such materials, softwood is used with a moisture content of not more than 18-22% and with no defects in the form of large knots, cracks, rot and wood tree parasites. In the absence of sawn timber of the required cross section, pairing of thinner sawn timber into one element is possible. Composite beams are assembled in the same way in the absence of sawn timber of the required length.

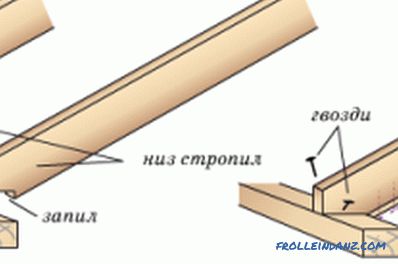

Scheme of connection and fastening of rafter legs.

Roof systems are not limited to this material only. Reinforcing elements can serve as metal products, which will give the wooden structure even greater rigidity and reliability. However, the use of metal has its drawbacks, which consist in the formation of condensate on the surface of metal structures with a temperature difference that could cause an increase in humidity in wooden structures and their subsequent decay. Therefore, in the places of contact of metal and wood, it is necessary to treat wooden products with special compositions or to equip their waterproofing.

Fasteners of rafters

The fastener elements can be used groove-tongue joints, previously known in construction. True, the modern installation of such fasteners are no longer used. The usual combination of structural elements are nails and staples. Their disadvantage is that over time, the rigidity of such a connection decreases due to changes in the geometric dimensions of the fastened elements, because the dimensions of wooden products may slightly change under the influence of moisture. More reliable are bolted connections of structural elements.

But they also have the disadvantage of weakening structural elements as a result of their drilling. Recently, the American technology has become known for combining truss structures using shaped fasteners and self-tapping screws, the choice of which in stores offering building materials has expanded significantly.

Typically, when building a residential building, roof systems are assembled on site. In this case, despite the seeming ease of working with wood, carrying out these works is fraught with many difficulties. Therefore, it is desirable to involve a team of experienced roofers with extensive experience in assembling and installing truss structures.

Calculation of rafters.

Reinforced concrete structures in residential construction were not widely used due to their heavy weight, complexity of installation due to the need to use lifting equipment and the lack of possibility of using individual construction solutions.

The emergence of new construction technologies has led to changes in the approach to the manufacture of truss structures. Recently, the technology of mounting rafters made of light steel thin-walled structures (LSTC) has spread widely, due to which the costs and terms of installation are significantly reduced. This technology is applicable in almost all types of construction of buildings for any purpose.

Advantages of roof systems

The supporting elements in this case are structures made of Z and C-shaped galvanized steel beams with perforation cuts, which can reduce the thermal conductivity of the element by almost half. The rafter construction is made according to the developed project in factory conditions and delivered to the consumer.The advantages of such structures include the following qualities:

- low weight of the structure, which allows the use of load-bearing walls with a lower design load and lower material consumption;

- shortened construction time;

- manufacturing accuracy and, consequently, the geometric dimensions of the truss structure;

- possible installation in winter conditions;

- no waste and the need for their disposal;

- reliability and durability of the structure from LSTC;

- environmentally friendly ma material;

- low operating costs for the maintenance of truss structures;

- effective heat saving due to the use of modern heat- and waterproofing materials in the truss structure.

The roof, and especially its frame, largely determines both the appearance of the house itself and its life span, and the state of the atmosphere of the interior. It will not satisfy anyone to look at the roof of a house, which has bent due to incorrect calculation of loads or walls covered with fungus due to permanent leaks.

Therefore, irrespective of the material of the truss structure, wooden or metal, the scheme of supporting structures requires a careful approach to their design and no less careful in installation.