For any room, a properly installed floor is especially important, because it is this part that accounts for the constant increased exploitation and heavy loads. Therefore, laying plywood on the floor is considered one of the best options for creating the perfect floor surface. This smooth coating serves for a long time regardless of the coating material itself.

Plywood flooring creates an excellent, level surface and lasts a long time.

Features and types of material

Specialists use plywood as the main and ideally even coating to level the floor surface. Preference for this particular material has been considered optimal for a long time, because plywood is laid equally well on concrete and on ordinary wooden logs.

Table of characteristics of various types of plywood.

At the same time, the material itself is notable for its particular moisture resistance, but nevertheless, its basis is wood, which, under the influence of water, quickly loses its original qualities. As a result of this factor, plywood is not used for leveling floors in such rooms as loggias and bathrooms, that is, where a sharp change in temperature and humidity is constantly observed.

What kinds of material exist:

- FC - water- and moisture-resistant on a urea resin, it is strong and elastic;

- NSH - unpolished, glued with casein glue;

- G1 - processed on one side;

- G2 - processed from two sides.

Laying Methods

Before the plywood is laid directly on the floor, some mandatory rules must be observed. This means that work should begin after the completion of all construction or repair work associated with the walls of a particular room and the ceiling. And in order to avoid possible distortions and cracks on the floor in the future, all work should be carried out only on a well-dried basis.

Layout of plywood on a concrete surface.

In this case, it is important to de-energize the electrical wiring and do not forget to process all wooden elements with a special water-based antiseptic.

The material is laid in the following ways:

- Mounted on a concrete surface.

- Installation on logs.

- Installation on a wooden floor.

The coating of the concrete or cement base can be started immediately on the screed, provided that the pouring is sufficiently even. But if the alignment of the sexual base is required, then in this case wooden lags are used.

It is important before starting work to thoroughly clean the entire work surface from the previous coating, as well as to sweep or vacuum the work area.

Installation on a flat concrete base

- First, the entire work area is carefully treated with bitumen varnish. In advance, a manual electric saw or electric jigsaw is cut into squares of plywood from 8 to 18 mm thick. Finished sheets need to be expanded in a run without attachment and numbered.

- If you plan to lay linoleum on top, then in this case you can use special glue, for example, bustilat. In the case of using parquet, in addition to gluing, plywood sheets must be additionally secured with self-tapping screws. At the same time between the sheets should be left gap to 3 mm.

- In a plywood sheet, drill holes in the corners, in the center and in the middle of the sides for self-tapping screws. At the same time, blind holes are made in the concrete and the dowels are driven there. Glue is applied with a spatula on one side of the sheet. Then, with extreme caution, place the plywood in the intended place and fasten it with self-tapping screws with a drill or screwdriver.

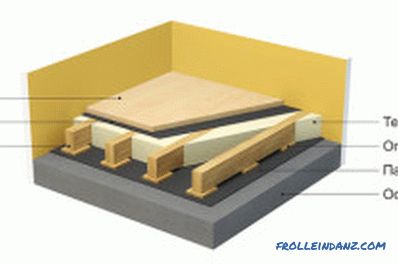

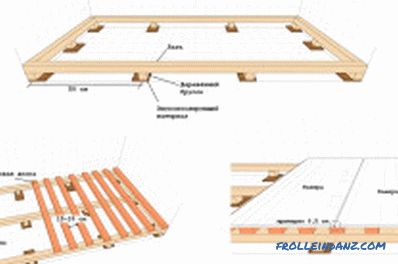

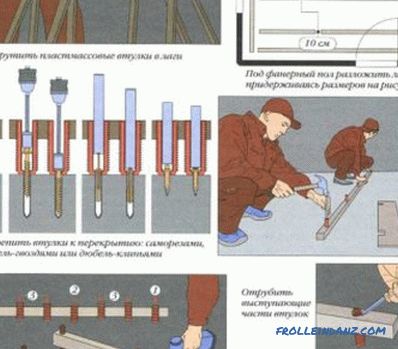

Installation on lags

Plywood floor installation on logs.

If there is humidity or constant temperature changes in a particular room, then in this case it is recommended to use wooden logs as the basis for plywood sheets. And also if the floor at the final stage is planned to lay a laminate or parquet. Usually for lags unplaned boards (100 mm) are used, which must be kept for a week in this room. After a week exposure, the lags are rejected, that is, those boards that have gone arc left and used as cross bars.

For installation of plywood sheets on logs take material with a thickness of 12-20 mm. Before you start laying lags, you should determine the possible differences in the working surface. This can be done with level and roulette. Lags are laid in increments of up to 600 mm so that all the edges of the sheets lie flat on the lags. Preparation of the entire working area is carried out, as in the installation of a concrete surface. That is, the entire work area is cleaned of debris with a broom or vacuum cleaner.

Stages of flooring:

- The voids in the crate are filled with thermal and waterproofing material. Polyurethane, for example, is well suited for this.At the same time between the lags and the insulating material empty space should not remain.

- Lay plywood sheets with a gap of up to 3 mm.

- Plywood sheets are attached to wooden lags with glue “liquid nails” and then fixed with nails.

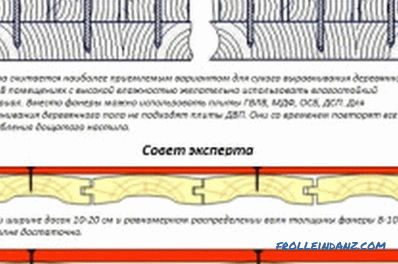

Installation on a wooden flooring

Laying the plywood on the plank floor.

With the help of a level and a tape measure it is necessary to find out the differences in the wooden covering. If small deviations are noted, they can be corrected with a special substrate. In the case of a drop of more than 1 cm, wooden logs are laid horizontally. If you plan to use linoleum or carpet as a floor covering, then plywood sheets up to 10 mm are suitable for this. For laminate or parquet, it is necessary to choose sheets from 12-20 mm thick.

- When conducting assembly work with plywood sheets for a wooden base, they use cutting and numbering of the material, as in the case of concrete pavement. Sheets are best laid with shear, like brickwork.

- When mounted on a wooden floor, logs are attached to the floor with self-tapping screws.

- The location of the horizontal lag is determined by the level and the tape measure.

- After the crate is made, the size of which should correspond to the plywood sheet.

Laying and fixing plywood to logs is carried out using self-tapping screws. But before that, all wooden blanks are carefully treated with a special antiseptic. Upon completion of all work, additional processing of all plywood sheets and wooden lags is required. The choice of material for processing directly depends on the flooring itself.

Used tools and materials:

- water-based antiseptics;

- bituminous varnish;

- polyurethane;

- self-tapping screws;

- dowels;

- glue "liquid nails";

- nails;

- broom or vacuum cleaner;

- electric saw or jigsaw;

- drill;

- trowel;

- drill or screwdriver;

- level;

- tape measure.

Using plywood sheets as flooring, experts can level any base properly. It is important that such a layer of plywood is an additional insulation of the room. But now they began to use plywood not only for covering walls, ceilings and as a rough laying on the floor. Recently, this material has become increasingly relevant in the decorative compositions of the interior of any room.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building in case of serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.