One of the most important components of the roof truss system is the batten. It is intended for placing and fixing on it various roofing materials. In addition, an important function is to create the necessary ventilation gap between the roof covering and the layer of insulation to prevent the formation and accumulation of condensate. Proper installation of the batten is an important element that ensures high strength and durability of the roof of the house. If you have time, desire and certain skills, assemble the roof lathing with your own hands will reduce the cost of making the roof. Let us consider more details of its manufacture.

Selection and processing of materials

Timber for grating

Timber for grating

As material for the production of crates should be selected dry wood that does not have knots and other defects that can cause cracking and breakage of the bars. In some cases, special roofing plywood can also be used for the batten. To protect the wooden elements of the roof from various parasites and exposure to fire, they must be treated with antiseptics and special fire-fighting compounds. Better impregnation can be achieved by performing work with a paint brush, with alternate application of two layers of the composition.

Types of battens

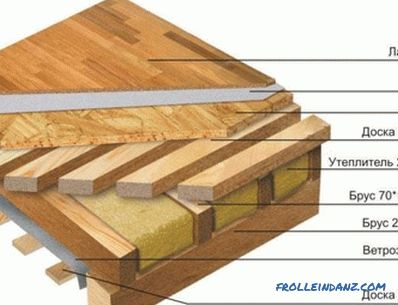

Installation scheme

Installation scheme

Depending on the roofing materials used, used crate several types.

Solid. It is used when mounting the sprayed roof, soft roofing materials, shingles and roll materials. When it is made on top of the first draft layer, perpendicular to it, the boards or bars are packed tightly (with a gap of up to one centimeter). In a simplified version, the lathing can consist of a single layer that is packed perpendicular to the rafters.

Sparse. Recommended when using sheet roofing materials with sufficient area. Slate, ondulin, metal tile and other materials can be used as these materials. The cross section of the timber for the manufacture of the batten is selected on the basis of the weight of the roofing material and the design loads from the winter snow cover. In any case, the cross-section of the bar should be ≥ 5 cm. The step of stuffing the bars should correspond to the selected roofing material.

Lathing for some types of roofing materials

For different types of used roofing coatings, there are specific features for the manufacture of lathing.

Under soft roof

Crate for soft roof

Crate for soft roof

It is made as two layers of solid wood flooring. The batten should be:

- strong to withstand the weight of the installer, roofing material and precipitation;

- as reliable as possible;

- even (with no kinks and corners so as not to to allow bending and friction of the roofing material).

As a material, it is recommended to use calibrated planed boards, roofing plywood or grooved boards, which allows to obtain a very flat surface.

Under roll materials

Lathing for roll materials

Lathing for roll materials

Running in the form of double or solid crates, can withstand the weight of a standing person without deflection. The thickness of the used bars or planks should not be ≥ 25 mm, and the width should not exceed 150 mm (to prevent their deformation).

In the manufacture of solid crates, the presence of cracks, protruding nail heads, knobs, and other irregularities is not allowed.

Under metal

It is made in the form of a trellised skeleton made of cut-off bars with an edge equal to 6 cm. The step of mounting the bars depends on the type of metal tile used (the main parameter is the profile) and the angle of inclination of the roof slopes.

Due to the high requirements for the strength characteristics, high-quality bars, calibrated to the same size (or sorted), should be used for the battens.

Under the ondulin

Depending on the angle of inclination of the roof slopes, several variants of its manufacture are used:

- Angle not more than 10 °. The crate is made in the form of solid flooring from special moisture-resistant plywood or boards.

- Angle from 10 to 15 °. The crate is assembled from 40x50 mm bars parallel to the cornice with a step of 45 mm.

- Angle over 15 °. The crate is made of 40x50 mm bars with a pitch of 60 mm.

To make the specified interval between bars more convenient, it is recommended to use a special wooden pattern.

Waterproofing

When installing the batten, waterproofing must be performed using a special film mounted with an overlap of 15 cm.Consistently installing the film from the eaves to the ridge, it is necessary to provide ventilation gaps, which should be placed between the roofing material and the film, as well as between the insulation and the film.

A properly assembled lathing made from high-quality materials will ensure reliable fastening of the roof covering and, consequently, a long service life for protecting your home from the vagaries of nature.

Video

Step-by-step instructions on preparing the roof for metal tile installation: