More and more people are becoming convinced that an autonomous way of heating an apartment or house is more economical than a centralized one. Do-it-yourself steam heating is one of the hardest tasks, but quite doable if you have some basic power tools skills. Even before the installation, it is necessary to make calculations and purchase the necessary components.

The essence of the question

Water heating

Water heating

Some get confused and believe that in fact, the correct name of such a system is water heating, and the prefix "steam" remained from the past times when heating was carried out at the expense of industrial boilers that produced large volumes of steam. In fact, even today there are boilers that provide space heating by converting the fluid into two states of aggregation. The strengths of this solution are:

- double heat transfer - by convection, as well as infrared radiation;

- minimum losses in the heat exchanger when energy is transferred from the source;

- high reliability;

- there is no danger of defrosting the system during the cold season;

- it can be used at any time of the year;

- long service life without failure.

Some disadvantages are:

- relatively high temperature of pipes and radiators;

- serious consequences of a breakthrough;

- some difficulties during installation ;

- high susceptibility to corrosion.

The essence of the operation and high efficiency lies in the fact that the steam, passing through the main line, condenses and settles, thus producing a large amount of thermal energy. At the same cost of fuel, such a system will be much more efficiently similar in length to water.

Usually, in order to ensure the safety of users, in modern boilers there are certain restrictions. For example, the maximum temperature to which the steam is heated is 130º C, and the highest point reached by pressure is 6 atmospheres.

Types of systems

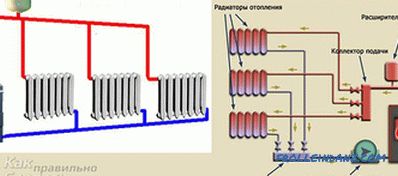

All types of systems are divided into single-circuit and double-circuit. In the first embodiment, all the power of the boiler is used to heat the carrier, which will take part in increasing the air temperature inside the room. In the second variant, there is an additional heat exchanger, in which the flow of running water is heated, which allows it to be used for domestic needs. When implementing the second option, it is worth remembering that it will be necessary to make additional connections to the boiler room and return them back to the living room.

Different heating systems

Different heating systems

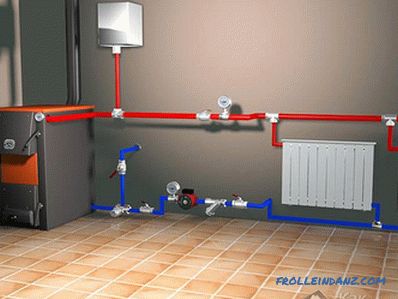

By the method of circulation of the carrier, as in the case of water systems, there are :

- Natural circulation or closed. In this case, after condensation, water under the influence of gravity by natural current without a pump returns to the boiler, where it is again converted to steam and used.

- Forced circulation or open. In this case, the water does not immediately fall back into the heater. Initially, it is collected in a special reservoir, from which it is pumped with the help of a pump for further conversion into a gaseous state.

According to the level of pressure inside, there are:

- Atmospheric. In them, the pressure value is several times higher than atmospheric, which in the accident can cause serious injuries. In addition, in such a system, emitters are heated to a high temperature, and the settling dust burns and an unpleasant smell is emitted.

- Vacuum. To implement this option, the entire highway must be sealed. With the help of a special pump, a vacuum is created inside. The result is a transfer of water to the gaseous state at lower temperatures, which increases safety.

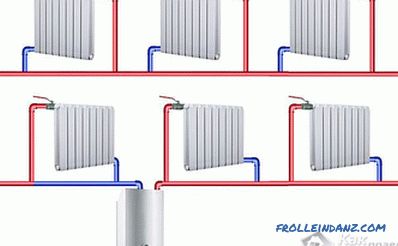

According to the method of distributing pipes, the following are distinguished:

- Single-pipe. Steam moves continuously along one pipe. In the first half of the journey, he gives up his energy to radiators, gradually turning into a liquid state. In this case, the temperature of the radiators, which are closer to the boiler, will be higher than those that are at the end of the circuit. In this case, you will need large diameter pipes to avoid any obstacles.

One-pipe heating system

One-pipe heating system

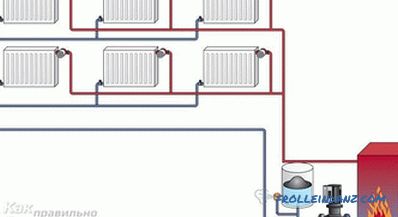

- Two-pipe. Steam is supplied through one pipe, and condensate is returned through the other. In this case, the carrier reaches all devices, practically without losing the temperature. This option will be relevant for large houses in which there are several floors. If the premises are small, it does not make sense, it will only increase the total cost of the project.

Two-pipe heating system

Two-pipe heating system

Vacuum systems are still at the testing stage. When using them, the constant availability of electrical energy will be necessary, since the vacuum pump operates almost continuously.

Choice of boiler

Choice of boilers

Choice of boilers

In order to properly pick up the heater, the first thing you need to calculate the area that will be heated. To do this, you need to calculate the area of each individual room by multiplying the width by the length. After that, all the results must be added, the final figure will be the desired value. It is important to remember that this is true for ceiling heights of up to 3 m, if it is larger, then it is necessary to make additional headroom.

- For a total area of up to 200–300 m 2 , there will be enough productivity in 25–30 kW.

- For 400‒600 m 2 - 35‒60 kW;

- 600‒1200 m 2 - 60‒100 kW.

The next step is the choice of fuel. Steam boilers easily operate from the following sources:

- Liquid. This could be, for example, diesel fuel or used oil. When using this option, it will be necessary to place the unit in a separate room. This will help avoid inhaling harmful fumes and their negative health effects.

- Solid - wood, coal, peat and everything that can burn with the release of a large amount of heat.

- Gaseous. Usually it is natural or liquefied gas.

- Electric.

In some cases, solid fuel solutions cost much less, but you should consider not only the cost of fuel, but also the time that will be spent on kindling. In this case, it can reach several hours, while it is necessary to constantly replenish the furnace in order to maintain the temperature at the proper level.

Some manufacturers combine different fuels. For example, they combine a furnace for loading solid fuel and provide the presence of heating elements. At the same time, efficiency does not fall, but it turns out to save on costs, and therefore on payments.

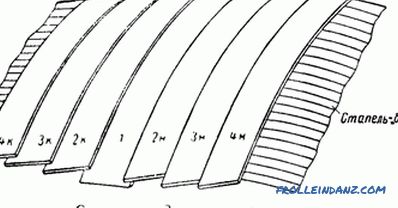

Choice of pipes

Types of pipes

Types of pipes

When you select, there will be a lot depend on the planned budget. What can be said for sure - for systems of this type polypropylene pipes are by no means used. It is explained by their instability to high temperature conditions. You will need to choose from the following options:

- Steel pipes. For their installation will require a welding machine. They are resistant to high pressure and temperature values. The positive side is also an affordable price and prevalence. The disadvantage is high susceptibility to corrosion.

Straight-seam steel pipe

Straight-seam steel pipe

- Galvanized pipes. They include all the advantages of steel, plus the lack of corrosion imbalance is compensated here. The joint is made using threaded connections, so welding is not required.

Galvanized pipes

Galvanized pipes

- Copper. Are the perfect option. But they are much more expensive in terms of cost; moreover, their installation will require special soldering skills for this material.

Copper pipes

Copper pipes

When mounted, pipes can be hidden in walls or floor. But it is important to take into account that the building material is resistant to thermal effects.

Additional nodes

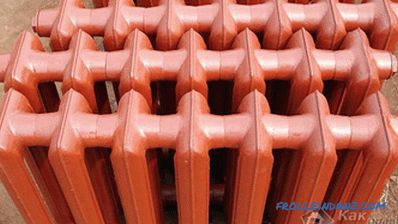

Cast iron batteries

Cast iron batteries

Except for the boiler and pipes for the highway, mandatory elements are required, without which it cannot be avoided:

- Radiators. These can be cast iron batteries, steel products or pipes with fins. Install them better under the windows. Thus, a heat plug is formed, which cuts off cold air. This will also prevent the formation of condensation on the panes.

- Fittings. Various connecting elements: couplings, angles, elbows, adapters, which will be required when installing the pipeline.

- Reduction cooling unit. Translates steam into a liquid state.

- Reducer. Designed to adjust the pressure in the system.

- Expansion tank. It is better to use an open element. If there is a desire to put a sealed tank, then it must be equipped with a pressure gauge and a pressure relief valve. If this is not done, it can lead to its failure.

- Condensate collection tank.

- Circulation pump. For systems with forced fluid movement.

- Hydraulic shutter. It will be necessary in the case when you need to drain the system for its repair or replacement of any components.

- Filter. It will be necessary to remove solids before water enters the boiler. This is necessary so that nothing reduces productivity.

- Mayevsky's cranes.

The installation of an indirect heating boiler is possible in the steam heating system. You will need a valve for three inputs. It connects to the thermostat and redirects the movement of the coolant.

Preparatory work

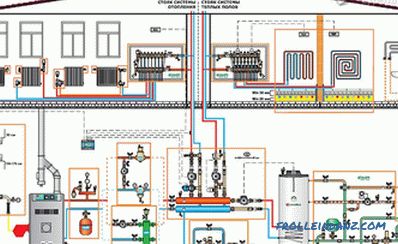

Scheme of the heating system in the house

Scheme of the heating system in the house

First business will need to make a drawing. On a sheet of paper is applied to the floor plan in which the installation will be carried out. The location of the boiler is determined. It is desirable for him to allocate a separate room. This is done in order to ensure maximum safety. If it is a closed system with natural circulation, then it should be at the lowest point. This is necessary so that water can flow freely to it.

The wiring of the entire system is applied, as well as the location of all the elements that were listed in the previous section. When performing this step, it is better to be in a particular room, then it will be possible to plan everything in the best possible way, taking into account the need to bend around the pipeline around obstacles or projections. All corners and transitions should be noted on the diagram. Once the drawing is completed, you can most accurately calculate the material that will be needed to successfully complete the entire project.

Some craftsmen make a steam boiler themselves. It is either boiled from sheet material, or a special contour is made from pipes, which is laid inside a brick stove. In the second case, it will be necessary to monitor the condition of the heat exchanger, which is best made of stainless steel, which will extend its service life. It is also very important to clean the smoke paths more frequently.

Sequence of actions

Steam solid fuel boiler

Steam solid fuel boiler

According to the marking done on the diagram:

- The boiler is mounted. In the room where it will be, must have a concrete base. If necessary, a small foundation is made.

- It is connected to the exhaust system.

- Emitters are suspended. To do this, use hooks that are designed to withstand their weight. About the place in which they should be located, mentioned above.

- Each radiator must be equipped with a Mayevsky tap to clear air plugs.

- At a short distance from the boiler, at the highest point, the expansion tank crashes.

- A pressure gauge and a relief valve are installed at the outlet of the boiler, which will operate in the case when the pressure exceeds the permissible limits.

- All components are connected to each other using pipes made of the selected material.

- If it is an open system, then a special tank and pump are mounted at the end of the line.

- From the pump to the boiler there is a supply pipe of a smaller diameter than all the heating.

- Before entering the boiler, there is a filter that retains large particles.

- If gas is used as a carrier, then a rigid supply is made without any flexible hoses.

- The fluid is being filled into the circuit.

- A test system start-up is performed with a gradual increase in temperature to verify integrity.

Heating Installation

Heating Installation

In this article, we discussed in detail how to make steam heating private houses. We would love to know about ready and functioning projects. Share your experiences and observations in the comments.

When installing heating in a wooden house, you need to take into account the specifics of such a structure.

Video

Watch a video on how to make heating properly: