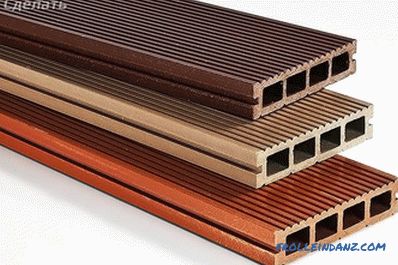

Thanks to innovative technologies, today we can create an analogue of natural materials. The quality of these materials is so good that they can even replace them. For example, natural wood has long been used to decorate cottages and cottages, terraces, shipbuilding and for arranging sites around the pool. But thanks to modern technology, there is material that is not inferior to him. This is a composite decking.

Such a modern building material is made of wood-polymer composite, which includes shredded wood and purified polymer. Decking has properties of wood and plastic. Moreover, it is not necessary to open it with varnish, paint or other means. Therefore, if you want to use this material for your terrace, then we suggest that you familiarize yourself with information on how the decking is done with your own hands.

What the composite board consists of

The properties of such a board are unique, as is its composition. Consider three features:

- The main component that is part of the deck board is wood flour. It is mined by grinding fine wood in flour. This wood component is carefully ground and dried. In quality material, 80% of the composition is wood flour.

- The second important component is thermoplastic polymer composites. Thanks to them, the surface of the board acquires its main functionality.

- In order for the functions of the tree to perfectly interact with the polymers, technical modifiers are added to the composition.

Unlike wood, such a board has several advantages: it is durable, does not lose its decorative effect, color and shape under the influence of various factors. This cannot be said about wood. Moisture, wood pests, fluctuations in decking temperatures are not terrible.

Main characteristics

Terrace board is gaining more and more popularity among consumers. And this is not surprising, because it has several advantages:

- Flexibility. Due to the fact that the molecules of polymer composites have a physical bond, it can disappear when heated and appear when cooled. Therefore, when you install the board, it can take any form and bend. This allows you to use decking not only for the decoration of terraces, but also for walls, ceilings, sheathing steps, protrusions. Thanks to him, you can make curved decor elements.

- Reliability. Modifiers in the composition make the material very durable and durable. A decking floor withstands a load of 1 ton per meter. And the cold and the heat it is not terrible, since it is not damaged when cold at -500 ° C and heat up to 700 ° C.

- Persistence. Since the polymers are resistant to mechanical damage, then chipping, scratching, stains from household chemicals absolutely will not.

- Easy care. Constantly painting the surface is not necessary. It can be cleaned with detergents using microfiber or a damp sponge.

- Moisture resistant. Thanks to this property, it is possible to use the material for finishing of pools, baths, moorings, etc.

- Easy to install. Installation can be done by both a novice and an expert. Everybody can do it, due to the fact that specific tools and materials will not be needed.

- Perfect view. The range of colors, patterns and patterns is very large, so you can express your imagination by decorating your porch the way you see it, giving it an aesthetic look.

Among the shortcomings, it can only be noted that such a board will be expensive. Usually the average price for 1m 2 ranges from 2 to 4 thousand rubles. And this is 4-6 times more expensive than regular wooden floor. But durability, functionality and other advantages mentioned above, cover such a high price.

Start of work - preparation of the foundation

Preparation of the foundation

Preparation of the foundation

To install decking polymer, you need to perform preparatory work. The main condition for comfortable installation work should be a solid foundation. It is important that it be perfectly smooth and even. Wooden bars, cement screed, plate or logs can serve as the base. If grass is actively growing on the place where future decking will be, then the soil must be treated with herbicides and covered with a special material.

In order to prevent water from accumulating on the floor and under it, the base should be made with a small bias of 1.5-2%. The bars are installed parallel to the descent, so that the water flows from the surface to the place of its discharge.

For air circulation between the boards, the slots are made, and the space under the frame is made empty.

Tools for work

You don't need special tools to make a decking. Everything you need is always at your fingertips.These are the tools that are used when working with ordinary wood:

- electric jigsaw or saw;

- drill or screwdriver;

- Bulgarian;

- construction level and roulette.

Self-tapping screws and special clips will be used as consumables. Tools are simple and specialist skills when working with them are not needed. Now let's look at the technology of laying decking.

Installation

If the base (frame) is made correctly, the installation will not be difficult. The main thing is to perform everything correctly and slowly, following the instructions:

- It is recommended to install the material at air temperature not less than 5 ° C. Moreover, one day before the work, unpack the material and let it "breathe".

- We proceed to install. The first board must be laid from a fixed structure. It may be a wall. The board must be fixed with screws. Maintain an angle of 45 ° to the reference lag. The last plank is done on the same principle. Holes for screws better to do in advance.

- The next step is to fix the boards to the support lags. This is done with the help of plastic or galvanized special clips. They allow you to create the same gap along the entire length. These clips can be purchased at a specialty store. Some lags even have a special recess under the clips, where they are fixed with self-tapping screws. Step by step, the straps are attached to the fulcrum.

- When the installation is complete, the ends of the decking boards that protrude beyond the edges should be cut off.

As you can see, everything is simple. This process is somewhat similar to the installation of the wall panel, only in this case, you need to leave gaps for ventilation.

How to avoid errors

In such work, you should take into account the mistakes that are made by those who have not read the instructions. In order not to spoil the material, consider these points:

- Be sure to make gaps for ventilation between the lags, as this will prolong the life of the material. And the gaps between the boards will preserve their integrity with temperature changes.

- Self-tapping screws or other fasteners do not overtighten, they will contribute to decking deformation.

- Properly arrange the water flow.

- Make drainage holes. They contribute to the fact that water, snow and other precipitation will not remain on the surface.

In order not to spoil the board, composite lags should serve as a support. Wood does not have such a long service life as a polymer. A concrete screed as the base will ensure the reliability and durability of the structure. If you have questions on the topic, then ask them to our site specialist. Maybe you have a desire to give additional recommendations to our readers? In this case, write comments on the article.

Video

In these videos, you will be able to visually familiarize yourself with the installation features of the decking: