A warm and cozy natural wood house for your family is a dream of many. Such housing has long been sought-after and popular, thanks to the many advantages, the main of which are environmental friendliness and a good microclimate.

A wooden house has long been considered to be the best. It is completely safe, environmentally friendly and has a beneficial effect on health.

Different technologies are used to build wooden houses. Some of them are very laborious and require a large amount of manual work, while others, on the contrary, are fairly simple, allowing housing to be built in short lines.

Construction in a log house

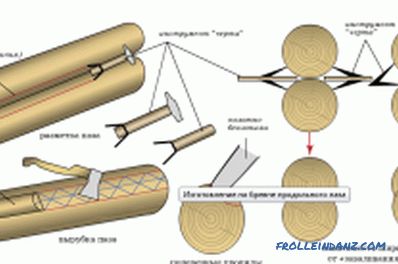

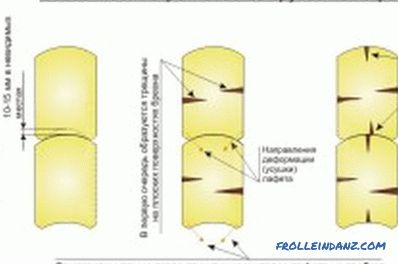

Scheme of preparation of logs for building a log house.

A log cabin is a very ancient technology, representing a simple construction of horizontally laid logs. For construction use coniferous woods with straight and long trunks. Depending on the climatic conditions, the thickness of the logs used may vary. For example, if in winter the temperature drops to -20 degrees, the logs used in the construction must have a diameter of at least 15 cm.

One row of logs interconnected by special cuts is called a crown. The connection can be made "in the bubble" or "in the paw." The first option has a characteristic protruding end. Such corners will be very warm, but this method of connection leads to excessive consumption of wood: the required length of logs is increased by at least 50 cm. The “paw” frame has no protruding elements; The disadvantages of this technology are greater laboriousness and accuracy of the work performed, the need to arrange additional corner trim boards for insulation. To achieve greater adherence of crowns to each other, the logs are additionally fastened with spikes. In addition, all the cracks filled with insulation, for example, dry moss, tow, or modern seals.

Materials for the assembly of log cabins

Wooden houses-log houses can be built from traditional logs or more modern materials that have undergone additional processing. The oldest technology is considered to be “wild log” - fresh wood 25-40 cm in diameter is used for assembly. All logs are processed only along the fibers, manually. This ensures the preservation of the resinous outer layer and resistance to the influence of the external environment. First, a black frame is assembled without sealing the gaps between the logs and leaving it for shrinkage for 6-9 months, after which they disassemble the structure and reassemble it at the installation site, on the foundation. Between the crowns must be placed seal for insulation and shock absorption. Such log houses are durable, look great, but the technology of their construction is laborious and costly, requiring highly professional skills.

Scheme of assembly of a log from rounded logs.

A modern version of a log house is a log house made of rounded logs. In this case, the wood used is not conical, but cylindrical in shape, which greatly simplifies the construction process. In industrial conditions, logs give the correct shape of the cylinder, cutting off the excess. After that, fitting to the desired length, facing, sampling grooves and spikes, drilling the required holes. Rounded wood is one-third cheaper than wild logs, which reduces construction costs. Low thermal conductivity is achieved due to the excellent fit of the logs. Such houses are assembled very simply and quickly on the basis of the constructor principle, however, they require up to 6 months for the shrinkage process, after which it is possible to perform finishing work.

Advantages of log cabins:

- very low thermal conductivity;

- any construction is possible;

- excellent appearance.

Disadvantages:

- large labor costs;

- high cost;

- mandatory time for shrinkage of the structure.

Wooden buildings from timber

Compared to log houses, buildings from timber of various types require significantly less labor and time for construction.

This technology provides for the possibility of using:

- profiled bar;

- glued bar;

- mast.

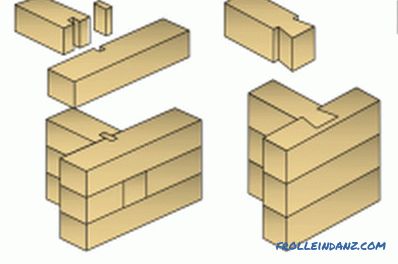

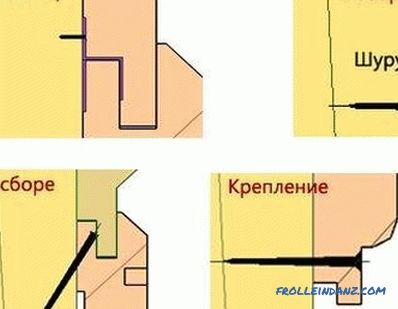

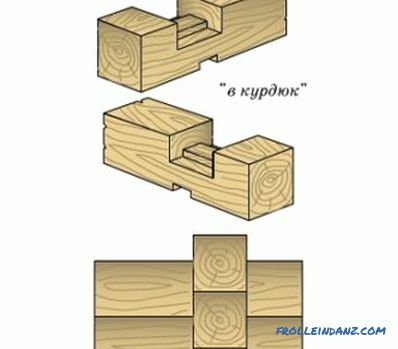

Scheme of options for connecting the profiled bar.

The profiled bar is made from completely dry wood, cutting from four sides. All docking units and connections, openings for windows and doors are manufactured in industrial conditions. This technology provides a very tight fit of the timber, so the device laying between them is not necessary. The construction of houses is done very quickly: the logs are stacked on each other and, if necessary, are tightened with metal pins. For greater reliability in the corners of the locks groove grooves.

The most modern material for wooden houses is considered to be glued laminated timber. It is made of coniferous wood, which is cut into boards, dried and glued under a press in such a way that the fibers of adjacent boards are located in different directions. The resulting material has a high strength, not afraid of moisture, freezing, does not form cracks. Houses built of laminated veneer lumber do not require time for shrinkage, their finishing can be started immediately upon completion of construction work. The disadvantage of this technology is the high cost of the material and the presence of glue in it, which reduces environmental performance.

Scheme for assembling a log frame from a carriage.

The carriage is a half-bar made of logs, sawn from two sides. Grooves and spikes are cut on the other two sides. To connect the laft use the "Norwegian lock": in the process of drying, the timber is wedged in the cup under the action of its own weight.

Advantages of a log house:

- fast assembly;

- high thermal insulation performance;

- do not need time to shrink;

- small labor costs.

Disadvantages of a log house:

- the cost of a bar is high;

- the inability to redevelop premises.

Construction of frame housing

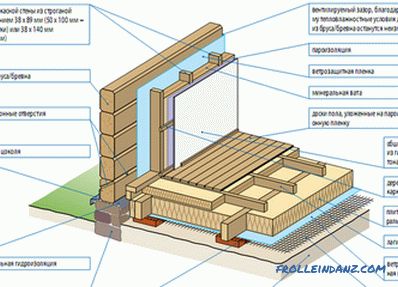

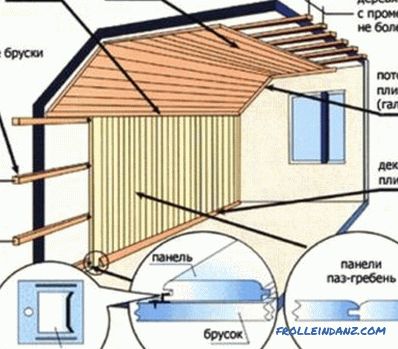

The essence of this technology lies in the construction of a post-and-beam supporting structure - a frame, which is then sheathed inside and out. The best material for the frame today is a timber made of glued veneer. The construction of the wall of the frame house includes:

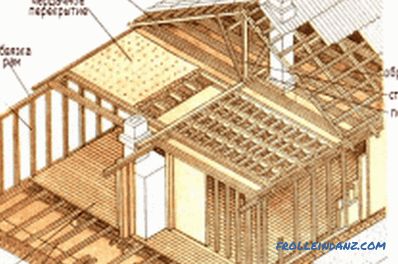

The frame of the frame house.

- inner and outer lining;

- insulation;

- vapor barrier;

- special windproof membrane;

- finishing facade layer.

For the construction of frame houses several technologies are used:

- frame-frame;

- frame-beam;

- half-timbered.

Frame-frame construction involves the assembly on the foundation of the frame: the lower and upper trim, struts and crossbars, between which make windows and doors. Fully finished frame veneer. Frame and beam houses are built on the basis of the same frame, but the walls are filled with a bar. Outwardly, such a structure is difficult to distinguish from a log house. The latest technology is used in the construction of luxury homes. It is here that only glued laminated timber is used for the frame.

Advantages of frame houses:

- fast assembly;

- possibility of creating different architectural structures;

- beautiful appearance;

- low cost.

Disadvantages of frame houses:

- mandatory use of insulation;

- less environmental friendliness;

- over time, replacement of insulation will be needed.

The variety of technologies used in the construction of wooden houses is quite large. Assessing the features, advantages and disadvantages of each of them, you can choose the most optimal and suitable option for your future home.

Didn't find the answer in the article? More information on the topic:

-

How to fix Euro-rail correctly?

Step-by-step instructions on how to fix the lining with your own hands. Materials and tools needed for work. Installation of this coating using klyaymerov.

-

Guide to covering the balcony with a tree

The process of covering wood balcony. The necessary tools and material for plating. Warming and creating a frame for plating. Features trim the walls of the balcony or loggia.

-

How to build a house from a bar with your own hands?

Instructions how to build a house from a bar. Erection technology, tooling, preparation and calculation of lumber. Warming and finishing works.