A heated electric floor allows you to create warmth and comfort in your home. Often the floors freeze in winter so much that neither carpets nor slippers help. Therefore, there is a need to mount the device for heating. This can be done without the involvement of specialists, because the installation procedure is not very complicated. In this article we will explain how to make an electric floor heating with your hands under the tile, laminate and linoleum, consider the various installation options, as well as show photos and video instructions.

Preliminary work

Preparation

Preparation

It is better to install an electric floor heating in warm time . This, of course, is not critical, but in the warm season it is much more convenient to repair the floor. In addition, work may always be required, such as filling a new floor.

- First you need to clean the surface. To do this, you have to remove the floorboards.

- Concrete must be well washed and dried.

- When the surface is dry, it should be leveled, if necessary.

Selecting the floor

Types of electric floors

Types of electric floors

Types of electric floors lots of. There are two main types of such systems:

- strong;

- single core.

The strong braids are best used in the nursery, bedroom and living room. They are more expensive, but, nevertheless, are considered the most environmentally friendly. Radiation from such floors is minimal.

It is better to install single-core ones in places where a person is not so often.

Among all types of flooring, the most popular is Heatlux. However, you can choose other options. If possible, then when choosing, it is better to consult with people who have already dealt with such systems.

Electric floor device

Electric floor heating device

Electric floor heating device

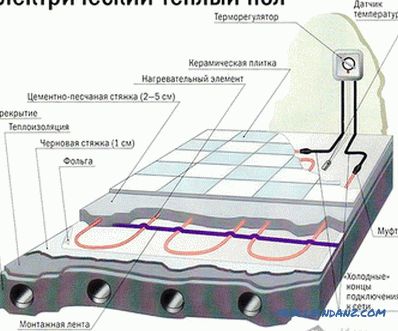

Before you make electric floor heating, it is necessary to understand its device. Installation is carried out on a heat insulating layer, which is made of a suitable material for this purpose. After installation, the floor is filled with a solution of sand and cement. After the solution hardens, any material can be put on top. This may be linoleum, and board, and another coating.

The electric floor functions due to the cable. The heating cable receives electrical energy, converts it into heat and gives it into space. Thus, the floor begins to heat up.

The installation process

The installation process

The floor is controlled by the thermostat. The cable that is poured in mortar is very durable. At least in well-known proven brands, it can withstand temperatures up to 100 degrees. Indeed, in the process of heat release, the cable also heats up.

If the cable sheath is weak, then a short circuit may occur. The floor will have to be repaired. This is more difficult and laborious than just installing the floor. Therefore, we must choose the system of proven companies and beware of fakes.

Floor installation

Installation of an electric floor

Installation of an electric floor

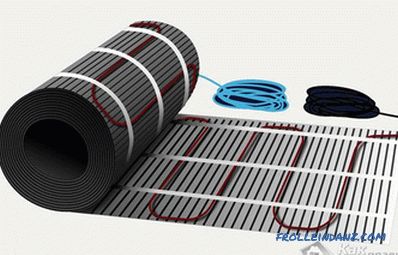

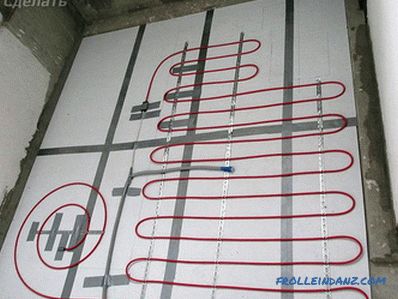

- Before lay electric floor heating, it is necessary to determine how long the cable may be required. The wire usually keeps within a snake. Determining the length of the cable, you must choose the very warm floor.

- The work begins with the making of the grooves in the wall. This is the place where the thermostat of the system will be placed later.

- Next you need to decide on the floor insulation. There are so many materials that can be put under the cable. The main thing is to take into account that they are not flammable and serve for a long time. The best option is mineral wool. The heat insulator layer is laid on the cleaned pre-floor.

- A mounting tape is laid on the heat insulating layer.

- The electrical floor cable is attached to the mounting tape. Cable laying is made by a snake.

- Next, you need to install a temperature sensor. The sensor wire will be located across the cable lines to transmit data. At the initial stage, the tube is mounted for this wire.

- When wires and cables are laid, it is necessary to indent 5-7 cm from the walls. Also, do not lay wires close to heating systems.

- Now you need to connect the cable to the thermostat. If the floor is strong, then one end of the cable is mounted, if single-core, then two.

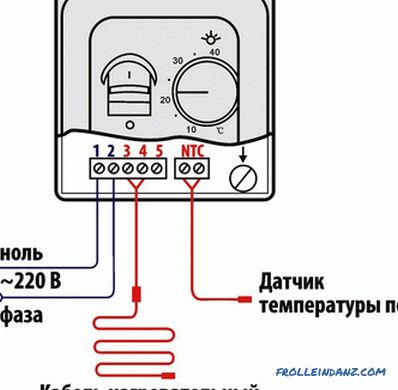

- It is necessary to connect the thermostat to complete the main part of the work. Three cables are connected to the device, which should be placed in the tubes. One of them is already connected, this is a floor cable. Now you need to connect the temperature sensor and cable from the switchboard. On how to properly arrange the wires, information can be found in the diagram located on the lid of the thermostat.

If you need more detailed instructions, you can see about the installation of a heated floor electrical video.

Finishing work

Underfloor heating - finishing work

Underfloor heating - finishing work

The floor is set, but there are still some work to be done. First of all, it is a floor screed. The surface must be filled with cement-sand mixture. Then the floor should be left alone until the screed is completely dry. The use of an electric floor during the period when the concrete dries out is prohibited.

It must be remembered that such a surface is very sensitive. Do not install heavy objects on it. Even if the room was previously massive furniture, the most difficult will have to be removed.

When the screed has hardened completely, any other topcoat can be made. It can be linoleum or tile. Only when the finishing work is completed, you can turn on the warm floor.

Under the laminate

Although electric floor heating is very popular, it cannot be combined with every floor covering. And this is explained not so much by the poor efficiency of the heating system, but by the specifics of its installation. So, the heating cable is first laid on the roughing screed. A reflective heat insulating material is laid under the cable, which will not allow heat to go down. After the flooring is heated, a finishing screed is poured in, and a laminate is mounted on top, all with the same backing. As a result, we get: the cable in the screed first heats the concrete layer, and only after that the thermal energy will flow to the flooring. But note that between the finishing screed and the laminate there is a layer of litter that will prevent the passage of thermal energy. Do not use the litter under the laminate is impossible, as this requires technology.

There is also another technology that eliminates the need to fill a finishing screed. A protective film and a sheet of chipboard or similar material are laid on top of the cable system. But again, such materials do not have sufficient thermal conductivity.

Electric heating for laminate

Electric heating for laminate

Therefore, the conclusion is that the installation of an electric floor heating under the laminate is not as effective as under tile or porcelain, the thermal conductivity of which is at a high level. If, despite all this, you decide to use electric heating for laminate, it is important to remember that such heating will not be basic, but only additional. Why? This is due to the fact that with a strong heating the laminate begins to release hazardous substances into the air for human health.

When the coating reaches a temperature of 27 ° C or more, formaldehyde vapors are released into the air. They have a negative effect on the human body, which leads to the development of diseases of the respiratory organs.

IR film for laminate

IR film for laminate

If you spend most of your life indoors, then This fact is important to consider. As is known, a person passes through himself up to 20 m 3 air per day, in the mass it is 25 kg. What if through the lungs will pass in the mass of a pair of formaldehyde? It is not surprising that in the choice of laminate and its heating system should be very careful.

Features of the choice of laminate

Not every type of laminate can be used for combination with underfloor heating. Although modern slats are equipped with excellent lamination. This laminate has a high level of thermal insulation, and under constant heating the coating itself will not deteriorate. But the problem is that such a laminate has a low level of thermal conductivity.

Given this, a new type of laminate was developed that also withstands constant heat and has a high thermal conductivity. Its difference lies in the special layer of lamination. Such laminate has a special distinguishing mark on the package, which allows its flooring to floor heating. It can be heated to 28 ° C without negative consequences.

Some manufacturers indicate the compatibility of the laminate with a particular heating. For example, laminate flooring is unacceptable for use with electric heating and vice versa.

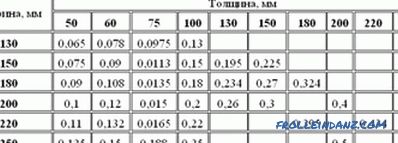

Another important selection criterion is the coefficient of thermal resistance (CTS). The higher this indicator, the greater the insulating index lamella has. Thus, according to the European standards EN, the bar should have a CCC less than 0.15 m 2 K / W. In this case, also consider the CTS of the substrate used. For example, if the selected laminate has an index of 0.051 m 2 K / W, and the substrate is 0.049 m 2 K / W, then adding these values turns out 0.1 m 2 K / W, and this is within acceptable limits.

What will happen if the CTS exceeds the indicated rate? In this case, the heating system will overheat, and this will adversely affect the duration of operation of the heating system and the entire heating cake.

The level of the CTS depends on the density and thickness of the laminate.Therefore, the optimal thickness of the strip for floor heating is 10 mm.

Under linoleum

The installation of electric heating for linoleum also has its own characteristics. This material requires a smooth and uniform heating. Thus, the heating power per 1 m 2 should be equal to 150 watts. This power is enough for the air temperature to reach 28 ° C and the floor for the linoleum to move comfortably barefoot. Otherwise, the linoleum will be subjected to intense thermal loads, and this will lead to the following:

- due to the expansion the material will separate;

- change the color of the coating;

- into the air the harmful substance phenol will be released;

- the material will soften, causing it to rupture.

Given this, not every type of electrical heating will work under the laminate. The infrared heat-insulated floor will be optimum.

Installation work on laying

Installation work on laying

As for the installation of electrical cables under linoleum, it is primarily made flat base Then the heat-insulating coating, the heating system itself and a thin finishing screed are also put. The system is equipped with a temperature sensor that will monitor the floor heating level. For such heating should choose high quality linoleum. However, it should not have a heat-insulating layer, otherwise it will reduce the efficiency of heating.

About the technology of installing infrared heating on the floor, you can read in this article "How to make an infrared heated floor."

Under the tile

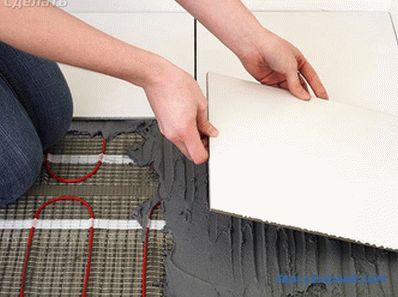

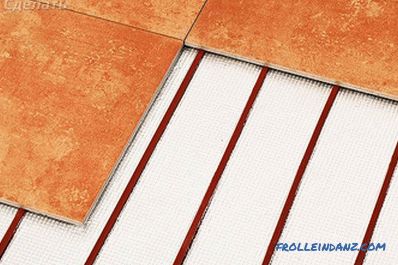

As mentioned above, a heated electric floor under the tile is considered the best combination option. In this case, it is possible to use both ready-made mats and a heating cable that fits onto the mounting bar. The only thing that is important to consider is some details when laying tiles on floor heating. To glue the tiles, you should choose the appropriate glue, which is adapted to high temperatures.

The advantage of electric heating under the tile is that it is not necessary to fill the finishing screed. This will significantly increase the heating efficiency. Glue is applied to the mats, and then gently with a notched trowel spreads over the entire surface of the floor, filling all voids. The thickness of the glue in this case should not be less than 5 mm.

During the glue drying process, a warm electric floor cannot be turned on. Glue should dry in the most natural environment. If you turn on the heating, the glue will dry out and begin to crack. And this, in turn, will damage the heating cable.

Video

The process of installing an electric floor heating is discussed in detail in the following videos:

Photos

Fixing on the mounting plate

Fixing on the mounting plate

Electric floor heating

Electric floor heating

Electric Floor Kit

Electric Floor Kit

Installing tiles on the floor heating

Installing tiles on the floor heating

Applying glue

Applying glue

Laying glue

Laying glue

Connecting the temperature sensor

Connecting the temperature sensor

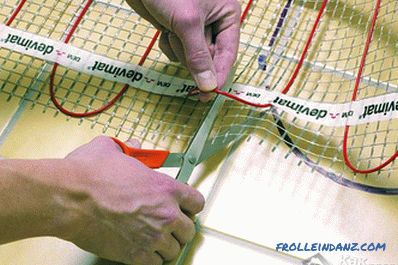

Trimming the mat

Trimming the mat

Core warm floor

Core warm floor

Tie to the warm floor

Tie to the warm floor

Laying roll bohreva

Laying roll bohreva

Laying the floor heating in zones

Laying the floor heating in zones