The trip to the cottage is a joyful event, as there you can take care of the garden or the landscaping of the plot, and then relax in the bath, provided it is there. We will tell you how to make a bath in the country with your own hands, demonstrate the drawings, diagrams and photo instructions. We'll have to work hard, but it's worth it.

In your imagination, you probably already see how you approach the bath, open the door and get into a warm and cozy dressing room, and then into the steam room. Yes! That's the way it will be, but a little later. First you need to:

- select a suitable project;

- familiarize yourself with the construction stages;

- purchase construction materials;

- build a bathhouse and let all communications take place;

- Perform interior trimming and then steam.

If, after reading the introduction, you have not lost the desire to make a bath at the cottage, then we will continue the topic, considering all the stages of construction.

Choosing a place for building a bath

A place for a bath should be chosen correctly

A place for a bath should be chosen correctly

Often, dacha plots are not large, but besides personal preferences and convenience, there are norms that must be adhered to. Consider the preferences first.

- It would be better to put the bath on a hill, which will greatly simplify the organization of water discharge.

- It is good when the bath is located next to a pond or river.

- The rays of the setting sun, penetrating the steam room through a window, will relieve stress, but at the same time it is necessary to make it so that the entrance to the bath is clearly visible from the window of a country house. So you can watch the bathing room and the children, especially when the pool is built before the entrance.

- A bath can be made in the form of an extension to the house.

In order to avoid conflicts with the authorities or neighbors, it is necessary to follow the instructions of SNiP 30-02-97. Paying attention to section 6, paragraphs 6, 7 and 8, you will find comprehensive information on the placement of the building on the site, but we will give only those numbers that you need in order to choose the optimal place for a bath.

Considering the fire safety measures for structures located on opposite sides of the passage, you need to adhere to the distances indicated in the table:

| Material, from which made bearing and enclosing structures | The distance, which directly depends on the material used in the construction of the building | |||

| I | II | III | ||

| I | Non-combustible materials |

6 m | 8 m | 10 m |

| II | The same buildings with the use of m of wooden elements | 8 m | 8 m | 10 m |

| III | Wooden and similar structures | 10 m | 10 m | 15 m |

Regarding the requirements relatively distances to the neighboring area, they are also unequivocal.

| No. | Minimum allowable distance between buildings located in the neighboring area | Distance |

| 1 | Garden House | 3 m |

| 2 | Different household buildings (it is possible to include a bath) are different | 1 m |

It is also important to take into account the requirements of the location of buildings on the site - from the garden house, the shower, bath and sauna should be at least 8 m away.

By the way, failure to comply with these standards may lead to a trial with a neighbor and demolition or transfer of the bath to another place.

Bath project

When choosing a bath project, it is important to take into account the material from which it will be built. There may be several types of buildings:

- Frame bath.

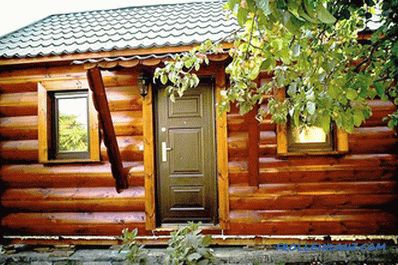

- Wooden bath (from a bar or a rounded log).

- Bathhouse made of brick, stone or blocks.

- Arbolite structure.

Having decided on the material, when choosing a project, make sure that it suits you by all criteria.

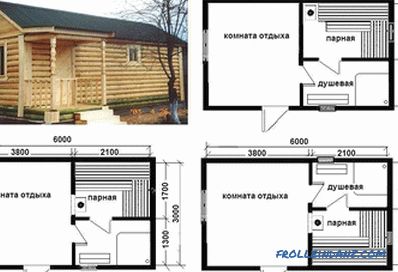

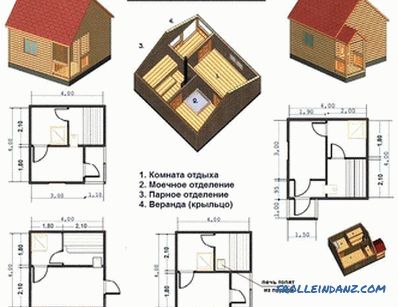

Planning a small sauna 6 * 3 m

Planning a small sauna 6 * 3 m

Option planning of a bath from a log house

Option planning of a bath from a log house

Planning a bath for giving

Planning a bath for giving

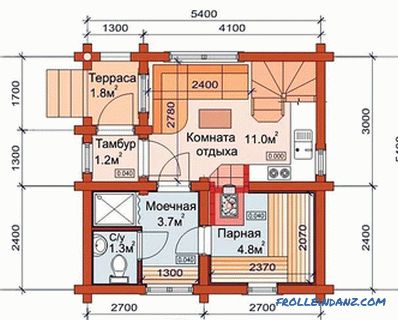

Bath plan 6 * 6 m

Bath plan 6 * 6 m

Material selection

So, choosing the appropriate project, in accordance with its requirements you need to prepare building materials.

- Most often gardeners prefer to build frame structures, as they are the cheapest and successfully cope with their task. In addition, in view of the low weight of such a structure, the foundation will also not have to be spent much.

- The most favorite buildings are wooden.The cost of such a building will be somewhat higher, and the foundation will need to be made stronger, unlike the frame structure. Built in the country a good wooden bath does not need insulation.

- Stone and brick are rarely used to build a bathhouse in the country. This is due to the fact that for such a heavy structure a strong foundation is needed, and walls freeze over during long absences and such a bath needs to be heated for a long time. The exceptions are buildings of foam and gas blocks. The strength of the foundation requirements are not so high, the walls are warm, but it is important to consider that this building material is very hygroscopic, so it must be protected from moisture.

- Arbolite is also often used in the construction of baths. Walls can be monolithic or erected from blocks. The structure is warm, durable and inexpensive.

Materials for walls

Since our article deals with several possible uses of different building materials, we consider them separately.

The frame structure

The material for the frame bath should be of good quality, and the bars should be dry and even

The material for the frame bath should be of good quality, and the bars should be dry and even

Walls of such baths are made in lattice construction. For the walls of the framework you will need:

- Bar of various sections, the size and quantity of which is indicated in the project.

- Insulating material with high thermal insulation qualities to fill the frame. Again, you need to adhere to the requirements for the use of a heat-insulating material, but here you need to take into account that the documentation often indicates one type of material, but not all possible ones. If the specified material is too expensive, then you can refer to the forums to clarify what is acceptable in your area.

- Material for trimming the frame from the outside and inside. Most often, OSB boards, edged boards, siding, or block house are used for building exterior cladding, while lining is used from the inside.

Wooden bath

Using a rounded log you can very quickly build a bath, since everything is prepared in advance at the factory

Using a rounded log you can very quickly build a bath, since everything is prepared in advance at the factory

For walling can be used:

- Natural peeled tree.

- Cut timber.

- Profiled bar.

- Glued laminated timber.

- Round logs.

Bath of brick, stone or blocks

The walls of such a bath can be made of the following materials:

- Brick (ceramic or silicate).

- Stone (quarrystone, limestone, shell rock).

- Block (foam, slag, aerocrete).

The structure of wood concrete

The wood concrete is durable and lightweight, therefore it is also often used in construction works

The wood concrete is durable and lightweight, therefore it is also often used in construction works

If there is an opportunity to purchase sawdust at a low price (and maybe there are some of your own), then at home it is quite possible to make arbolit blocks of fairly high quality. Also, this building material in the form of finished blocks is on sale. The walls are built very quickly. Another advantage of using arbolit is the possibility of manufacturing monolithic walls by pouring cement-shaving solution into the formwork.

Materials for the ceiling in the bath

The dressing room and the rest room are warm rooms, therefore it is recommended to use materials with low thermal conductivity - aspen, linden or alder.

For the ceiling of the steam room, it is preferable to use wooden lining, as it can withstand high temperatures. In this room you can not use products made of pine or spruce, when heated from this wood resin begins to stand out. Also, the ceiling should not be hemmed with sheets of hardboard and chipboard, as moisture and high temperature contribute to the release of vapors that can cause harm to human health.

Materials for insulation and vapor barrier

It is advisable to carry out external insulation only under the condition that the bath is heated. It is unlikely that someone will do this luxury in the country, so we are considering materials for internal insulation of an unheated bath.

The frame bath does not need to be insulated, since the thermal insulation is embedded inside the structure. In a wooden bath you need to make a crate, which is inserted into the insulation. Other types of baths need warming, made by a more complex technology.

To perform the work, mineral wool is required, the thickness of which is selected depending on the material used in the construction of the bath and climatic conditions. A layer of at least 50 mm is usually laid. Insulation can be in the form of mats or in rolls.

As for the vapor barrier, it is important to know that this is not waterproofing. Each has its own purpose. Even an inexpensive vapor barrier will fulfill its role, while waterproofing, used for other purposes, can negate all the works.

What you need to pay particular attention to is not to get a fake.

Finishing materials

Since this is a bathhouse in the country, we will not talk about luxurious types of decoration. The best option would be to use wood: clapboard or similar cladding materials.

As for the exterior, this can be any material that is used for covering houses. If the bath is made of rounded logs, then it would be unwise to close the already beautiful facade with something else.

Construction of a bath

Now we will look at how a bath can be built in the country with its own hands. It is clear that the work will be easier to perform with an assistant, which may be someone from family members. At the initial stage of work, some instructions can be given to children. Of course, they will do far from everything and not as quickly as we would like, but if they feel they need them, then they will be more careful about the bath built with their participation.

But let's be realistic, small children will help a little, and if you build it alone, it will be a long-term construction, especially since some work alone will not work. In the course of reading the article, you will see when and how many assistants you may need - this will help you plan everything.

Marking

So, the plan has been chosen, we have decided on the location, now we will start marking the terrain. To do this, in accordance with the scale specified in the project, transfer the contour of the bath to the terrain. In the place where the corner of the building will be, a long peg (or reinforcement) is hammered, and the lengths of two walls at an angle of 90 ° are measured from it. The following pegs are hammered there, and the distances of other walls are measured from them. Finally, the last is hammered - the fourth peg.

Now that there is a designated perimeter of the future structure, you need to check how straight the angles are. To do this, you need to check the axes - measure the distance from one peg to another. The data obtained must match. If this is not the case, then the plane needs to be shifted, shortening the longest axis. After that, it will be necessary to check not only the axles, but also other dimensions, and, if necessary, to correct them again.

If the foundation is tape, then a slight discrepancy can be left, but for the pile or pillar foundation, the marking should be very accurately performed.

So we designated the dimensions of the bath in accordance with the design data. Further marking is performed depending on what the foundation will be. More information about this can be found in the table.

| Foundation type | Where it is used and how the markup is used |

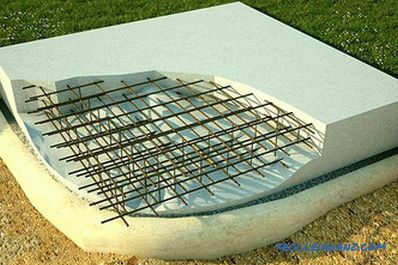

| Slab | This type of foundation, due to its high cost, is done only in cases when it cannot be avoided. The marking is carried out according to the size of the building or slightly larger, when it is necessary that the foundation be wider and longer than the bath. |

| Tape | A very common type of foundation. Relatively inexpensive and durable. The marking is carried out in such a way that the concrete poured into the tape runs along the perimeter of the building and under the relocations. |

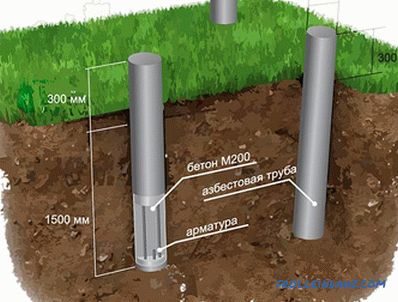

| Column | This type of foundation can also often be found. Mainly used for the installation of wooden buildings. Depending on the size of the bath, markup is performed according to the number of supports manufactured. |

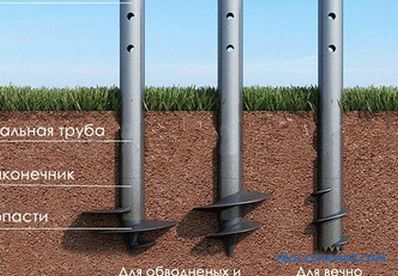

| Screw | It is believed that this type of foundation is new, but this is an erroneous conclusion made on the basis that it has recently been used in civil engineering. The screw foundation passed the test of time, as the military started using it long ago. The advantage of the foundation device on screw piles is the speed and simplicity of its installation. The second advantage is that there is no need to carry out earthworks, so the site will remain clean. In addition, it can be used to build a bath even on a site that has a significant bias. The marking is done by the number of piles and no deviation to the side is allowed. |

Weigh the pros and cons, and then make the final decision regarding the choice of foundation type.

Foundation filling

Manufacturing of a shallow strip foundation is acceptable under the following conditions:

- The soil is dry and non-flowing in the soil.

- The groundwater level is quite low.

- In winter, the frost is not very strong.

- Buildings are not heavy.

Do not try to guess the type of foundation for a heavy structure.If you are not sure, invite specialists who, having performed the appropriate checks, will give an exact answer.

Let's start with the simpler and most frequently manufactured for a bath shallow foundation.

- We have exterior markings, now we need to perform internal ones, taking into account the fact that the width of the foundation must be at least 50 cm, and must extend beyond the limits of the structure by 510 cm on each side. Therefore, if the bath is 3 * 4 m, then the largest size along the outer perimeter will be 3.2 * 4.2 m.

- It is important to take into account the installation location of the furnace and at the same time make the foundation for it.

- For convenience, in the corners you need to install wooden structures that look like benches. They need to be set in the same plane along the height of the future formwork and attach a measuring cord to them. How to do this is shown in the illustration.

For strip foundations, marking is performed both along the outer and the inner contour

For strip foundations, marking is performed both along the outer and the inner contour

- It is necessary to remove the fertile top layer of soil and put it aside, then dig a trench, the clay from which can then be used as bedding.

- As for the trench depth, in some cases it may be 35 cm. Much depends on the depth of freezing and the soil itself. You need to get to the durable clay layer and in no case dwell on the ground. Therefore, most often the depth is within 50–60 cm.

- The bottom of the trench needs to be leveled by checking its horizontal position.

- Now it's the turn of the sand bedding. It is necessary to pour a layer of sand at least 15 cm thick inside the trench, moisten it with water and tamp it well. For this, it would be more convenient to use the rammers, but you can also manually, using a weighty bar with handles nailed to it.

- The next layer is filled with gravel of the middle fraction and is also carefully rammed.

- Now it is the turn of the formwork, the height of which should reach the tensioned cord. You can make it from scrap materials or wood, harvested for other purposes, since this temporary structure will be dismantled soon after the foundation has been poured. Finished shields need to be installed along the trench and well fixed, otherwise the poured concrete can move them.

The formwork must be securely fastened. You can also immediately insert a sleeve so that you can carry out communications

The formwork must be securely fastened. You can also immediately insert a sleeve so that you can carry out communications

- In order not to dirty the boards, and to prevent concrete from flowing out through the slots, formwork from the inside It is closed with plastic wrap, which must be fixed with a stapler or thin nails.

- Now we need to make the frame of metal or plastic reinforcement, fastened with knitting wire.

You can perform all calculations in our online calculator.

- The fabricated frame should not reach the edges of 5 cm. It should be carefully lowered into the trench so as not to tear the film protecting the formwork. To raise the frame above the bedding, you need to put pieces of granite under it, as it, unlike a brick, will not crumble under the influence of moisture.

- If any communications pass through the foundation, then for them you need to leave holes, in what the liners will help, as is done in the photo above. The same applies to the manufacture of products.

- Plan your time so that the foundation is poured with concrete for the day, as breaks are unacceptable here - then the tape will not be monolithic. It is convenient to deliver the concrete with a mixer and pour it directly from it, otherwise it will have to be kneaded in a concrete mixer, on the basis that cement M400 will need 1 bucket, sand - 3, crushed stone (or gravel) - 5 buckets.

- The foundation poured with concrete should be sealed with a vibrator or pierced. After shrinking, you need to add some concrete and level the pad. If a base is made for a wooden house, then foundation bolts must be fixed in the non-frozen concrete.

- Not earlier than in a week you can remove the formwork.

It should be remembered that concrete has not yet gained full strength, therefore it must be treated carefully or wait 28 days and then build a bath.

Video: building a foundation for a bath

Masonry walls

When building a bath from blocks, stone or brick, you need to to level the foundation with a cement-sand mortar, and lay a roofing felt on it, folded in half. Masonry starts from the corners. Having installed the first blocks on the cement-sand mortar, you need to make sure that they are in the same plane and only after that a string is drawn on the upper outer edge, which serves as a guide for the laying of a number of building materials.

When laying the next row, the masonry mixture may differ: a brick and shell wall is erected on the cement-sand mortar, while the mixtures recommended by the manufacturer are used for masonating lightweight blocks.

Having installed jumpers above doors and windows, you need to install formwork on top and make armored belt, fixing foundation bolts in it for the subsequent fastening of the power plate. After the concrete has hardened, it will be possible to start making the roof.

Construction of the frame of the bath

The basis of such a bath is a frame made of wood, which is insulated and sheathed with various types of finishing materials. You need to choose quality materials and follow the sequence of their installation.

For the manufacture of the framework, boards from well-dried larch, aspen or linden will be needed, because this wood has a low thermal conductivity. Shields manufactured will be resistant to deformation.

On the foundation is made the frame of the lower trim from a bar 100 * 100 mm. At the ends of the bars need to make cuts in half the thickness and fasten with each other with screws. If bars are used 50 * 100 mm, then the frame can be assembled end to end with the help of metal corners. The size of the bar used depends on the type of foundation, design and size of the bath.

Production of the base for the frame bath

Production of the base for the frame bath

- In the next step, the end strapping board is installed, and Already attached to it are the floor logs. The bar is used 50 * 100 mm.

- On the opposite side, the logs are cut so that the second end trim can be installed.

- Lags need to be arranged so that between them the prepared heater becomes closely between them, then the end boards are nailed.

- The frame of the walls is assembled from a bar of 50 * 100 mm, and then installed in its place, all parts are fastened together in a single structure.

To ensure the vapor barrier of the frame bath, you need to use a vapor barrier film that will avoid the accumulation of moisture inside the frame. Mineral wool or fiberglass is used as a thermal insulation material. They are able to provide a high level of sealing without disturbing the natural air exchange.

It is preferable to carry out the insulation and wall covering after the installation of the roof. This approach will protect the wood and insulation from getting wet.

Floor

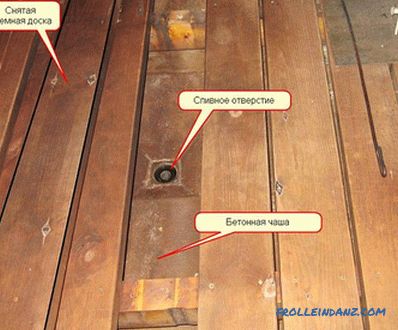

Construction of a concrete floor with wooden flooring

Construction of a concrete floor with wooden flooring

If in a frame bath it remains only to warm the floor and lay the floorboard, then for other buildings you will have to work harder - you need to install logs, make a subfloor, fix the vapor barrier, put insulation, perform waterproofing, lay the floorboard, which in a few years will have to be changed. Given that the cottage in the country will not be thoroughly dried due to lack of time for it, because after the weekend you will need to quickly go to the city, then if there is such an opportunity, it would be preferable to make a concrete floor and revet it with tiles. On it are stacked wooden shields, which can be brought out to dry in the barn and quietly go home.

Wooden floor with insulation

Wooden floor with insulation

It is clear that for the frame and other buildings installed on the column or pile foundation, only wooden floor with insulation is acceptable. More details about this process are described in the following two videos.

Video: how to install floor joists, make insulation and ensure the drain in the bath

Roof construction

Over any bath should to be a reliable roof, but the options for its creation may be different. In any case, you need to put waterproofing and then insulation, think about the type of roof and the choice of a suitable roofing material. Without waterproofing, steam will penetrate unhindered into the attic, and, settling on beams and rafters, will contribute to their rapid destruction. In addition, the condensate formed on the roofing material will begin to drain on the insulation, which will affect the properties and durability of the latter.

A large influence on the choice of the type of roof has a type of terrain, since it is necessary to take into account the technical parameters of the structure.

- So, in the holiday village, especially when it is located among tall trees, you can safely make a high gable roof.

- If the dacha is located in the steppe zone blown by all winds, then the slope for the roof should be made minimal.

- With a small bath and small snow loads, the roof can be made leaning. The same roof is often made in the bath attached to the house.

To avoid extremes and errors, we recommend that all calculations be performed in an online calculator. So you will have a clear idea of what type of material is suitable for a particular type of roof and how much it is required.

Video: how to make a roof of a bath

Interior and exterior finish

Although wood is most often used for interior decoration, not all wood is suitable for this purpose .It is necessary to choose the right material, especially for the steam room, in which high temperature is created at high humidity. Immediately it should be said that for the finishing of this room it is impossible to use sawn from pine, as well as fiberboard, chipboard and linoleum. Therefore, you need to purchase lining of larch or linden.

As for the other rooms, the conditions there are not so extreme, so there are no such high requirements for the material used - which cannot be used in the steam room, it is perfect for a rest room and a waiting room. Pine wall paneling in the dressing room will give off a pleasant aroma and create a feeling of comfort.

Finishing of wooden and brick bath clapboard is almost the same. First, the crate is fastened to the wall, and the lining is mounted on it. An exception is the steam room, in which the heat-reflecting foil should be under the crate.

Exterior decoration is performed not only to make the bath beautiful, but also to protect it. For finishing the bath from the outside, you can use the following materials:

- Imitation timber.

- Siding.

- Wall paneling.

- Block House.

- Facade tiles.

- Paint.

It remains for you to choose the appropriate material and decorate the facade.

Ventilation in the bath

Sometimes there is an opinion that good ventilation in the steam room is useless, because through it all the heat comes out, and it is made very weak, or it is completely absent. But there is another extreme, when the ventilation process is not controlled, and the heat evaporates from the bath. In such a steamy room at the top is very hot, and his legs feel cold.

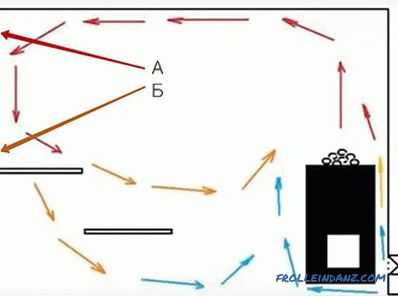

In fact, during the adoption of bath procedures, the air in the room should be updated 2-3 times per hour, but this is not enough, since the ventilation must be properly done. Usually the inlet is located near the bottom of the boiler, and the exhaust under the ceiling on the opposite side. While the steam room is warming up, the exhaust window is closed. Then it opens, and the warm air begins to rapidly out of the room. As a result, the steam room becomes cool and uncomfortable. You can make the ventilation, as in the diagram.

Scheme of air circulation in the steam room

Scheme of air circulation in the steam room

Such a device allows you to keep warm air under the ceiling and out half cooled through the hole located below (B), so it will be comfortable in the steam room. When you need to thoroughly ventilate the steam room, the upper vent opens (A).

In addition to the steam room, ventilation is necessary in every room of the bath. In order not to waste precious heat, you can make it possible to close the ventilation holes in those hours when there is no need for airing.

Furniture

The canopy and all the furniture for a country bath can be made independently. If there is no desire to make something else, then there are many offers on the network for the sale of everything necessary for the dacha.

With a strong desire to save on furniture, you can revise old stocks. Maybe there is something that needs to be repaired, but there is no way that hands reach this? After a small restoration of such furniture can serve a considerable time. The main requirement is not to use furniture made of chipboard, since this material will deteriorate very quickly due to high humidity.

Schemes

Bath plan 6 * 7.2 m

Bath plan 6 * 7.2 m

6 * 6 m

6 * 6 m

5 * 4 m

5 * 4 m

4 * 4 m

4 * 4 m

3 * 5 m

3 * 5 m

3 * 3 m

3 * 3 m

Photo: original baths