At present, many owners of country houses and summer cottages have fully felt all the advantages and advantages that automatic gates provide. Their installation allows the car enthusiast to quickly and without problems enter the territory of his plot, without wasting precious time opening the difficult and heavy entrance gates. The main thing is to correctly select and assemble the construction of the gate and equip it with a reliable and durable automatic system. Initially, it is necessary to determine the model of the door and its installation technology.

Sectional

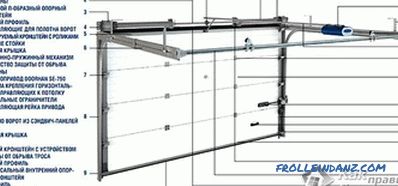

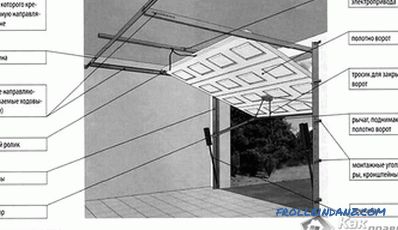

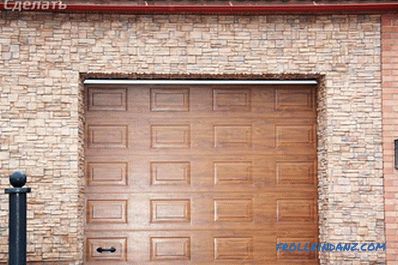

In many European countries, sectional doors are the most common type of protective device for garages and the entry area of a country site. In terms of technical equipment, their design is a separate section, interconnected by loops, moving along guides fixed along the aperture and displaced under the floor of the room. The movement of the canvas garage door of this type is carried out on a vertical plane. It is very convenient in everyday use, as it does not require additional space, allowing you to open the gate, even if the car is located directly in front of the entrance.

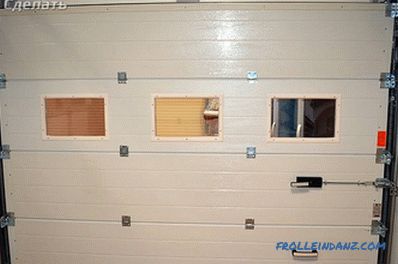

For ease of use, sectional doors can be equipped with a side door or a built-in wicket door.

A separate door significantly increases the convenience of everyday use of the garage, reduces heat loss in the room and increases the security level of the facility. Indeed, in the presence of a door or wicket, it is not necessary to fully open the gate to enter the box.

An important advantage of an automatic sectional door is the availability of a reliable and convenient access control system. You can pre-pick a rotating latch or a special valve for opening the system only from inside the room. To close the structure, an automatic bolt lock with a stable pin and a secure snap-on washer is installed outside.

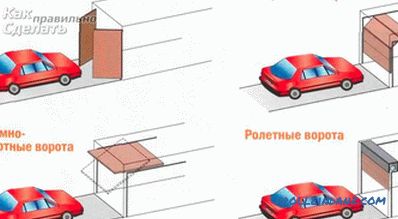

Species

Species

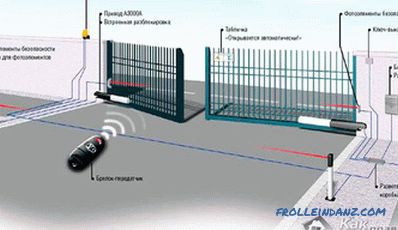

A well-chosen control system will provide the facility with high reliability at an affordable price. Mounted drive with closed door leaves is additionally a high-quality locking device.

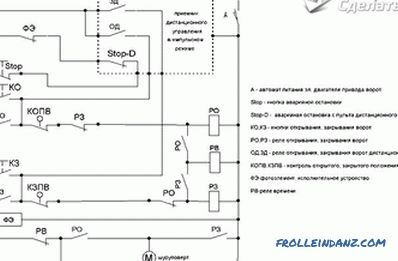

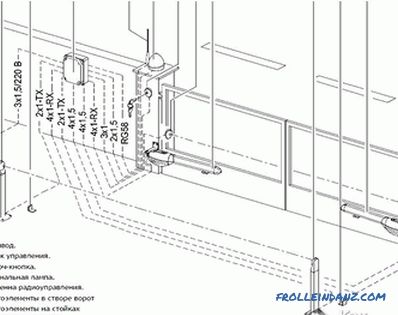

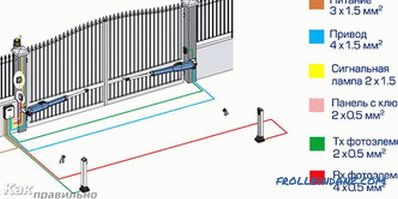

The gate is controlled by an electric drive using a remote control or a stationary device.

With the probability of permanent or temporary power outage, a special system is provided in the device for operative emergency shutdown of the automatic electric drive and activation of the manual control mode.

Sliding gates

Materials

Materials

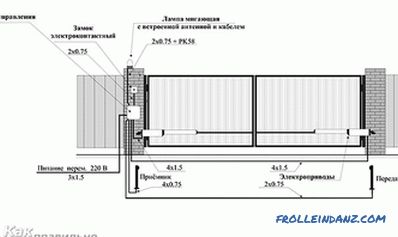

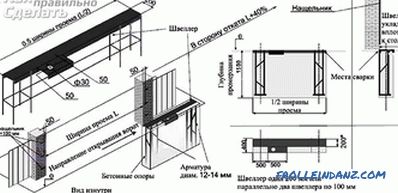

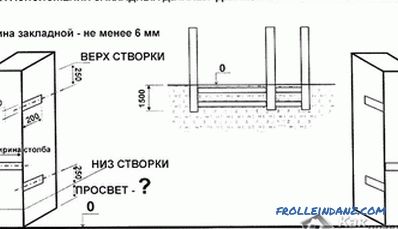

To protect the entry zone to any territory and its facilities are increasingly used sliding doors, operating in automatic mode. A steel cantilever pipe is welded to their bottom. In the course of its operation, the structure moves along roller carriages, which are installed on a special organized foundation. The lower corner of the sliding gate in the closed position is rolled into the catcher with an end roller. Such movement prevents lateral oscillations of the device during the opening of the web.

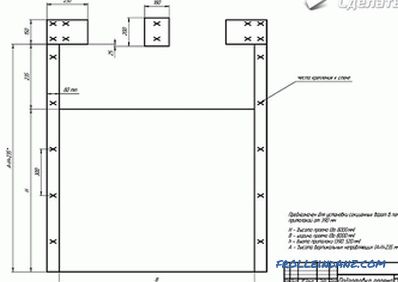

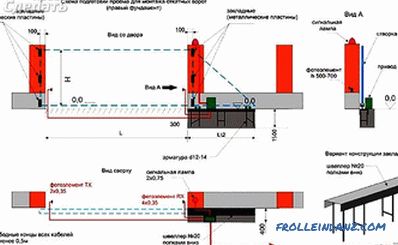

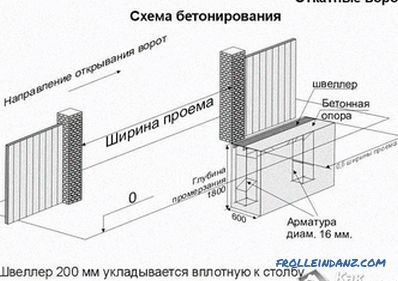

Concreting scheme

Concreting scheme

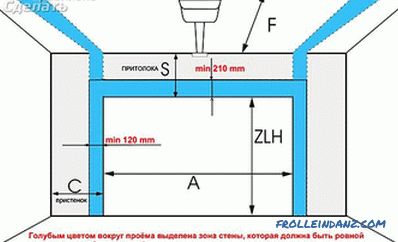

To install a sliding gate, an independent foundation is required.

The following should be considered:

- Installation begins with the arrangement of an independent foundation, the foundation located in the opening and on the side of it, in the direction of the opening of the structure.

- The frame of the sliding gates and their fastenings must have high wind resistance.

- Installation of a special holding part is required, which increases the width of the web construction in the direction of opening the gate.

- Sliding gates should be provided with an effective anti-burglary system and special protection against adverse external factors.

Video

The following video will help you to understand the device and the installation of a sliding gate in more detail:

Swing

Swing gates

Swing gates

Traditional hinged structures have remained the most common type of entrance gate for many decades. As before, they are still very popular today due to their affordable price, guarantee of safety and reliability of the system. In addition, they are very comfortable, functional and feature a large range of design and architectural solutions.

Today, beautiful and prestigious swing gates from a forged canvas, equipped with a durable and comfortable automatic opening system, are widely in demand. The frames themselves and the filling can be made of any building materials.

Automation

Automation

The design of the swing gates consists of the following elements:

- A metal frame made of steel pipes.The cross section of the frame is selected taking into account the size of the structure, wind and operational load of the canvas.

- Steel inner frame designed for finishing decoration with openwork forged products, sandwich panels, special wood or corrugated flooring.

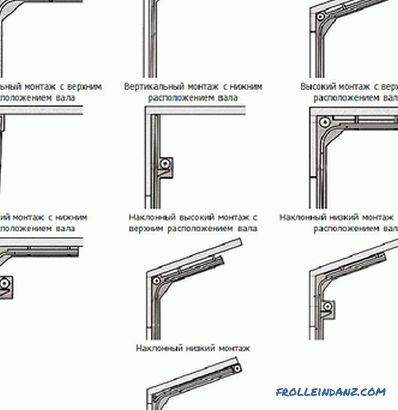

Restrictions on the choice of electric drive are related to the width of the door leaves and the total weight of each individual structure. Attention should be paid to the location of the automatic drive, which can be placed in different places. It is possible to fasten the drive to the doors or gate posts, to the supporting columns of the structure or outside the whole system.

Lifting gates

Lifting mechanisms

Lifting mechanisms

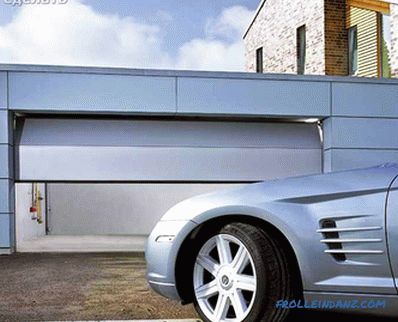

Regarding the sliding and swing gates, then they are used both for arranging garages and for entering the courtyard. Lifting gates are installed exclusively in garages. They represent the canvas, rising and shifting under the ceiling of the room.

Lifting gates are in great demand among consumers, as they are notable for convenience during operation, high protective properties against unauthorized entry, as well as an affordable price.

Subspecies

The elevating gate can be divided into 2 subspecies: rotary and sectional. If we talk in general, the design of these gates is similar, there are differences in the set of components, as well as the order and method of their installation.

The essential difference is that sectional doors are more mobile and flexible, are more reliable, and swinging structures are simpler. The safety of the latter is ensured only by the integrity of the web.

Sectional doors are made from sandwich panels and only, and for the pivot doors, a professional sheet, wood or insulated panels can be used.

Save money, do it yourself

There are 2 options for saving without loss of quality:

- Install the gate from the manufacturer according to the scheme attached to them.

- Independently manufacture the overhead gate according to the drawings.

Which of these options to choose is up to you. However, if you stop at the second option, it is better to immediately give preference to a simpler design of the overhead gate.

In order to save as much as possible on materials, you should accurately carry out their calculation in order to acquire the actually necessary quantity of them.

Construction

Construction

To save money, you can sacrifice the appearance of the gate by refusing to decorate it. As for the lifting mechanism, you can also save money here by installing a manual drive. But, you see, the use of an automatic electromechanical device is more convenient. I would not want to save at the expense of comfort.

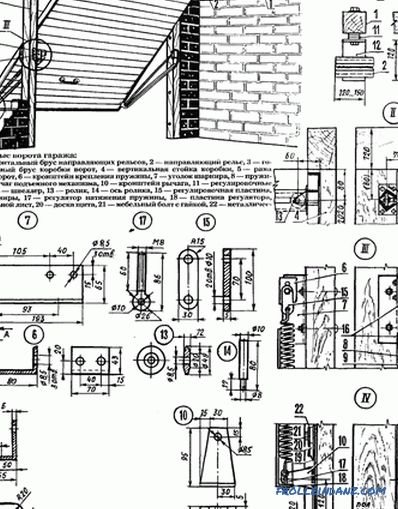

Technological sequence of manufacturing

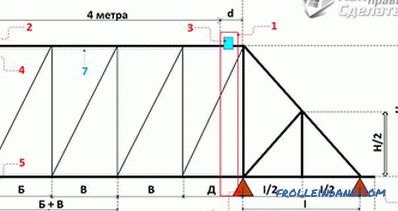

The main elements of the lifting gate are the frame, the canvas and the lifting mechanism. As the canvas can serve any material that would match the exterior of your home. The frame is made of metal profiles or square tubes. They can be fastened together by welding seam or bolt fasteners. With regard to the lifting mechanism, the choice here will be more difficult:

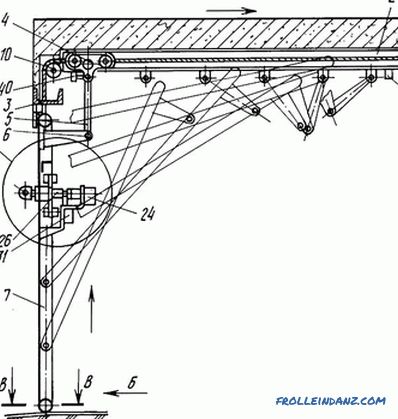

- Swivel-lever mechanism - involves accurate alignment of the guides vertically, ensuring smooth movement of the gate up / down.

- The counterweight system provides for the cable to pass through the block on which the counterweight is attached. This design has the right to life in cases when it comes to installing heavy gates.

Framework

Framework

So you will need:

- Profile / square tube for the frame.

- Fasteners.

- Channel Bracket.

- Pins.

- Spring.

Guide

Guide

First you need to make a frame. Dip it into the concrete base a few centimeters. It must be installed in the opening and secure with pins. After that, collect the canvas that you want to sheathe a metal shield. Make holes in the shelves for mounting the spring bracket and mounting to the racks. In addition, you need to make holes for the channel bracket on which the spring will rest.

Now you need to work with the spring. It must be connected to the bracket. This can be done using a metal adjustment plate. Then make the hooks and add a tension regulator below.

Running

Running

The next step is to make and secure the hinge and plate with the hole on the frame, and respectively, and the end of the lever. Then make the rails from the corners. One end of the rails must be welded to the plate mentioned above, to which the channel is welded. Then it needs to be fixed on the ceiling of the frame.

It is important to set the rails as horizontal as possible.So, you will ensure the smooth opening / closing of the lifting gate. Now we are installing the canvas, as well as automation.

Video

Photo

In the photos you can see the production options for the automatic gate:

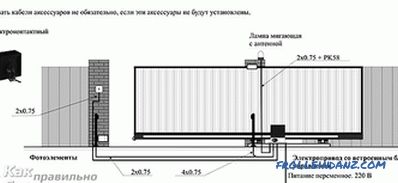

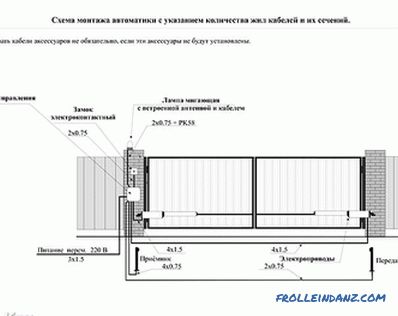

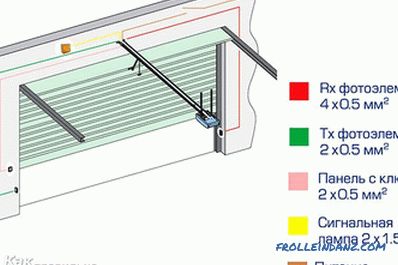

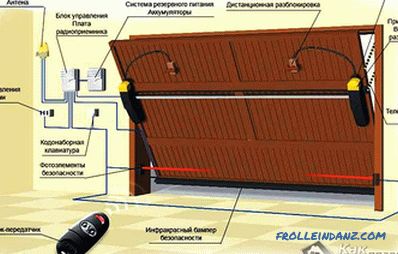

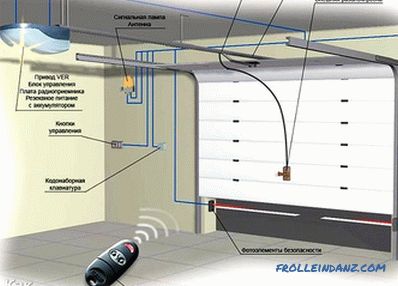

Schemes

The provided schemes will help you design your own model of automatic gates: