The tension fabric today is recognized as an aesthetic, fashionable and practical element for ceiling decoration. At the same time, many are interested in whether stretch ceilings are not harmful to health, since very often the unpleasant smell scares the consumer. In order to understand this issue in detail, it is necessary to study what a modern stretch ceiling is made of and whether harmful fumes are released during operation.

Chemical composition

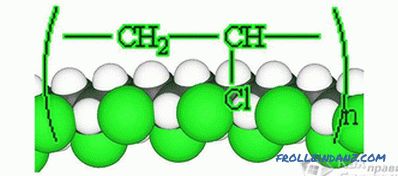

Polyvinyl chloride

Polyvinyl chloride

First of all, it is worth considering the composition of the most common type stretch ceilings, which are made of PVC film. Most tensioning cloths consist of polyvinyl chloride, which is a polymer. This polymer is produced from:

- phenol;

- cadmium;

- toluene;

- chlorine.

These components, when heated strongly, can release harmful substances in large quantities, which means they are harmful to humans. It is also worth noting that this is only possible if you choose a low-quality film, the cost of which is too low. If we talk about a high-quality product from well-known manufacturers, then when it is heated there will be a very small amount of volatile chemicals, namely phenol and toluene. They can be harmful to health only in great concentration.

PVC film

PVC film

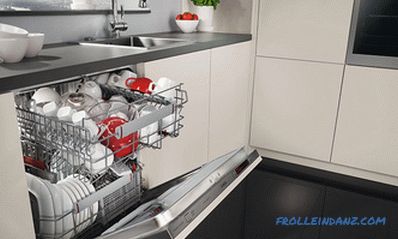

PVC has many advantages and positive aspects to consider when purchasing:

- moisture resistance;

- resistance to aggressive media (chemicals);

- incombustibility;

- easy installation;

- long service life;

- ease of care.

It is also worth noting that fabric stretch ceilings are no less popular nowadays. They are completely natural and environmentally friendly, so do not bear any harm to people.

In the modern world, polyvinyl chloride is used in many areas, especially in the manufacture of industrial goods. In accordance with international standards on the labels it is designated by the abbreviation PVC.

Opinions of experts and physicians

The ceilings emit a specific smell

The ceilings emit a specific smell

Each person has his own opinion on innovative materials, so they add up to legends. Many of them have a negative characteristic. But in order to know exactly how harmful stretch ceilings, you need to get acquainted with the opinions of physicians.

- Harm to human health. Everything that is produced and manufactured today must have supporting documents and certificates regarding quality. It is also necessary to have full compliance with international and domestic standards. Therefore, we can conclude that in the presence of the entire package of documents, one cannot unreasonably blame the material for causing harm.

- Toxic smell. One can agree on this score, but only partially. For example, if we talk about ceilings that are made on the basis of textiles, then they have no smell. But the PVC film emits a specific smell only for a few hours after installation. Enough to organize high-quality airing, to reduce the time period. If the smell has not disappeared within a day or two, this means that the material has a low quality indicator.

- No air circulation. The almost complete tightness of the stretch ceiling design suggests that it will be quite difficult for the air to circulate properly. This leads to a decrease in the amount of oxygen in the room. In fact, this opinion is absolutely erroneous, since the installation processes provide for the presence of gaps through which the flow of air will be normalized.

- Damage to the fabric. It would seem that the fabric stretch ceilings are harmful? But there are myths about this that are not scientifically proven. Diligent manufacturers use only environmentally friendly fabric, without the inclusion of synthetic fibers, which means that we can talk about their harmlessness.

Fabric ceilings

Fabric ceilings

To be completely sure of the quality of the product being purchased, carefully read the accompanying documentation: quality certificates, laboratory tests and technical indicators.

Choose a quality

Odor can be observed after mounting

Odor can be observed after mounting

Basic The criterion that should be armed in studying the quality of the film is the smell. After installation, it will be mandatory, but, nevertheless, the smell and smell are different. Therefore, it is divided into three main categories.

- Low odor. After the wizard has completed the installation in an apartment or house, there will be a faint odor for several hours or days. To get rid of the smell, arrange ventilation. Such ceilings will not cause any harm to residents.

- The smell lasts about a week.It speaks of medium quality material. To avoid harming the body, it is best to leave the whole family for a couple of weeks after the installation work, since such a neighborhood would not be useful. Also note that this product is not suitable for a bedroom or children's room at all, but it is permissible for a kitchen, bath and bathroom.

- The unpleasant smell did not disappear after two weeks. In contrast to the two previous options, this one has a sharp and sweetish hue. That is how phenol smells. So, this material is harmful to the human body and it is necessary to dismantle the canvas.

It is rather difficult and even unrealistic to determine the degree of odor before mounting the ceiling structure. To avoid an unpleasant situation, loss of time and personal funds should be addressed only to trusted companies and organizations. These will be able to advise you to your colleagues, friends and relatives who have already become owners of the ceiling and were satisfied.

To receive compensation for the provision of poor-quality material, always ask the supplier of checks and other documents that confirm the purchase.

Where the scales tilt

You can study this question for a very long time, each participant in the discussion will have his own opinion and stand on his own until the end. To resolve the dilemma about the dangers and benefits of stretch ceilings and take any side, you need to find out how the material behaves when heated.

As is well known, many materials are harmless themselves, but when the surface is heated, the structure can release harmful and dangerous pairs for the body. The same applies to polyvinyl chloride. So, after installation, a small smell very quickly disappears, but with the arrival of a hot and sultry summer, it is worth thinking about how the heat in the room will affect the material.

Odor occurs due to warming

Odor occurs due to warming

According to the technical parameters and laboratory tests, PVC film is not subject to change up to 65ºС. If the ceiling surface is exposed to a higher temperature, then the harmful substances will become volatile and will spread around the perimeter of the room. Thus, a person who is present in the room at this moment will endanger himself. But who can just sit in a room with an air temperature of 70 ° C or more?

When installing the ceiling, specialists use a heat gun that warms the film to the required temperature to give it elasticity. Experts advise not to be in the room at this time.