As one of the possible options for arranging rough flooring today, quite often, specific designs, called adjustable floors, are chosen. Arrangement of such structures involves the use of a lag system mounted on mechanically adjustable supports, due to which all procedures for leveling the base are noticeably simplified. In addition, when using such a foundation, it is still possible to adjust the position of ready-made floors during their operation (in areas of arbitrary area).

Construction

Scheme of an adjustable floor

Scheme of an adjustable floor

In order to make adjustable floors on lags, first of all you should be familiar with the principle of their device. Immediately, we note that in this case (by analogy with the traditional installation system), a clean floor covering is mounted on top of the base, consisting of special wooden boards or log.

The main difference between the mounting method we are considering and the classical scheme consists in a special method of fixing the genital lags, which in the first case occupy a strictly fixed position, since they are mounted on a static basis (on cranial bars). When preparing the adjustable base, the supporting bars are equipped with special movable sleeves with screw thread. Acting as supporting elements of the structure, such sleeves during rotation change the position of the logs vertically and correct the plane of the base.

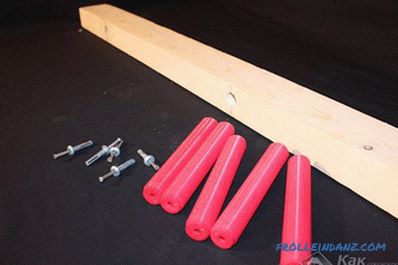

Rack bolts

Rack bolts

Thus, by rotating the sleeves embedded in the lags, it will be possible to raise or lower portions of the genital base needing adjustment. The possibility of alignment without dismantling is the main advantage of designs on adjustable lags.

Despite the seeming fragility of embedded plastic bushings, the strength of the floor assembled on their basis is quite high. To increase the bearing capacity of the draft base, simply increase the number of movable support bolts.

Material preparation

Preparation lag

Preparation lag

Adjustable floors are installed enough just under the condition that the organization of assembly work strictly fulfills the following requirements:

- Wooden bars made of coniferous wood that do not have cracks, chips, knots, as well as obvious signs of rotting are selected as supports.

- The quality of the plastics from which the bushes are made and their holders should not be in any doubt.

- To extend the life of the structure, its wooden elements should be treated with an antiseptic. In addition, to exclude the possibility of fire of wooden parts, the latter are treated with flame retardants.

- In the event that there are no ready holes in the blanks of the floor lag, you will have to prepare them yourself using a special drill, whose diameter is 1.0-1.5 mm less than the cross section of the plastic sleeve itself. This approach ensures maximum rigidity of the landing support in the material lags.

Drilling holes

Drilling holes

Preparing the base

Before you make adjustable floor, you should carefully prepare its base, which should be sufficiently rigid (best of all, if it is a concrete slab or screed poured over the subfloor).

Prepare the floor

Prepare the floor

To prepare the concrete foundation, you will need to do the following:

- clean the plates of debris and dirt;

- perimeter cracks and crevices with the help of the grinder cut to a depth of about 30 mm and then filled with epoxy-based sealant;

- to increase rigidity process the top layer of concrete with a special reinforcing mixture (sold in dry or liquid versions);

- lay waterproofing on the reinforcing material.

The above preparatory operations will allow you to get a reasonably solid base, as well as provide the required microclimate in the space under the floor.

Assembling the construction

Pre-placement of the lag

Pre-placement of the lag

Direct assembly of adjustable floors should be done taking into account the following recommendations:

- Ready-made lags with holes for the supports are pre-dispersed on the base surface with a pitch depending on the type of future coating.

- For tile or linoleum, this distance should be about 40 cm, and for covering from parquet or laminate it is chosen within 60 cm.

- There is a small gap between the wall and the extreme lags (about 15 mm ).

- A gap of not less than 3 cm must also be provided at the joints of the sexual bars stacked longitudinally.

We advise you to take full responsibility for the requirement to comply with the specified temperature gap necessary to prevent possible deformations of structural elements when the temperature and humidity of the air in the room changes.

Installation of support columns

Installation of support columns

At the next stage of installation, you can proceed to the installation of the lag using adjustable the height of the plastic racks. To do this:

- using the holes in the bars as guides, drill holes in the concrete base to accommodate the dowels;

- insert the support legs into the holes and bait them on the threaded connection. When screwing in carefully, make sure that small chips or dirt do not get inside the threaded connection;

- then hammer dowels into concrete slots and fix the prepared support legs in them;

- adjust the log position using a special key aligning them on the ground plane. We make sure that the maximum difference in height does not exceed 1 mm per 1 running meter.

Alignment

Alignment

The elevation of the supports should be started from the edges of the cover, gradually moving to its center.

Speakers cut with a grinder

Speakers cut with a grinder

After all adjustment operations are completed - you will need cut the protruding parts of the support sleeves with a conventional chisel or grinder Try to fix the struts of the structure as rigidly as possible so that over time they cannot loosen. All subsequent flooring operations are performed in the generally accepted order.

Video

This video footage from the beginning to the end shows the process of mounting an adjustable floor on the logs: