How is the connection of rafters with a power plate made? The strength and reliability of the roof under construction provides the roof system, which is the basis of the roof structure. The quality of the roof depends on the strength of the connection of its individual elements.

Fixture for rafters.

Materials and tools:

- rafters;

- mauerlat;

- saw;

- hammer;

- wire;

- studs;

- templates;

- nails;

- clamps;

- brackets;

- steel angles;

- bolts, nuts, washers;

- steel plates;

- self-tapping screws;

- brackets.

A necessary condition for a high-quality roof assembly is the correct installation of ridge beam and mauerlat boards. If at installation of the truss system any mistakes are made or the fastenings of the parts are performed poorly, this can lead to the deformation and destruction of the roof.

Therefore, the work is carried out according to the rules and technologies specified in the building codes that regulate the installation of the roof.

Types of truss systems

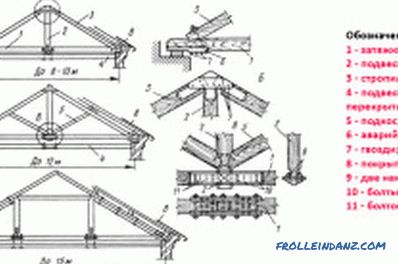

Typical types of truss systems used.

Rafter connections may be waved or hung. Therefore, different methods of fixing elements.

The weight of the roof and boards creates a certain load on the walls of the building. This load must be uniform.

Fixation units are divided into the following types:

- installation of the boards during extension;

- installation to the power plate;

- installation of components to the special parts, which ensure the reliability of the roof structure.

Scheme of rafters.

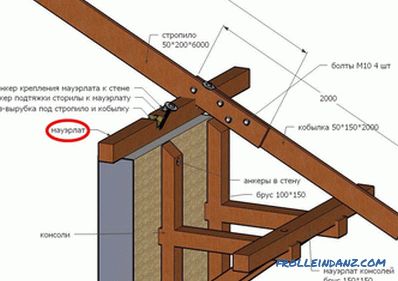

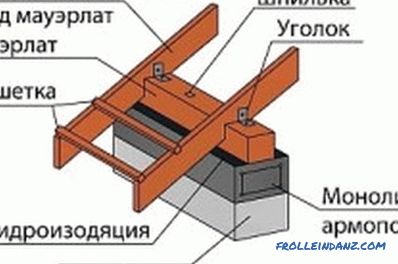

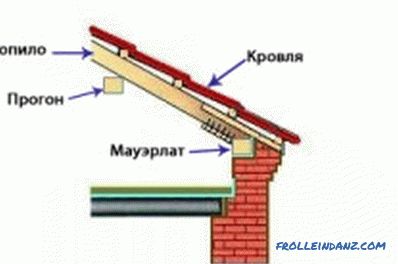

Mauerlat is a large beam, which is laid along the axis of the supporting walls parallel to the ridge of the roof.

The Mauerlat is a bar that has a cross section of 15x15 cm. It is fixed to the supporting wall with studs that are brickled in concrete.

This is done with a wire that is used to tie up the support bar.

In construction, there are two methods for fixing rafters to a power plate.

The first method provides for rigid fixation of planks and beams, the second - a sliding fastening.

Hard connection between the rafters and the power plate

Attaching the rafters to the power plate.

Rigid fixing of the boards is used when mounting the nylon beams. In this case, you need to firmly install the truss foot on the beam.

There are no additional loads for turning, shearing, twisting or sliding at this node.

The required rigidity of the knots can be achieved in two ways: by attaching a retaining bar to the boards and by means of a trim which is carried out on the rafter leg.

Installation of boards with cuts to beams

Key elements of hanging rafters.

First of all, on each leg, a cut is produced using the appropriate template. At this stage, the depth of the saddle is not more than 1/3 of the height of the bar. After that, the rafters are installed with a saddle in the power plate and fixed with nails. They are nailed on both sides of the board at a certain angle to each other. Then another nail is vertically hammered. This creates a fairly rigid reliable connection. This method is used when installing the roof in construction in most cases.

In the mauerlate, the rafters cannot be cut, as this may result in the destruction of the structure. Cutting is done only in truss boards.

In case of rigid installation, the beams evenly distribute the effect of loads on the bearing wall of the building.

Another method of connecting the rafters and the mauerlat is carried out with the help of a special meter bar, which is suspended from the rafter leg. Meter bar rests on the bar. For fixing the bar used metal corners. They do not allow the rafter to move in any direction.

If during the construction of the roof on one side of the rafter leg a rigid connection has already been made, then on the other side use a different look.

When weather conditions change, the wood from which buildings are made can change its shape. If rigid fastenings are made on both sides, this may cause additional loads on the frame of the building. This may cause deformation of the bearing walls of the house.

Sliding attachment of rafters and power plate

Layout of the roof with a sliding support.

This type of compound is used in the construction of houses from logs or lumber.

After the construction of a building is finished, the wood changes its shape for a few more years, shrinks or expands. Thus, the shrinkage process at home is carried out.

At this time, the elements of the roof truss system also shrink. It is precisely because of this that it is impossible to perform their rigid connection, otherwise it may cause deformation of the whole building. Therefore, it is necessary to provide a certain freedom of movement in the attachment points of the rafters and the power plate.To do this, use the installation system, which is referred to as a sled. Use metal corners, which have elongated holes for connections.

Installation of spacers and hanging boards is carried out using clamps or staples. In addition, you need to attach the truss legs to the bearing walls with wire twists. As a result of such an attachment, the roof will not move when the wind is gusting.

When shrinkage of a wood house occurs, the installation of rafters using a sliding method ensures the reliability of the roof structure of the house.

Methods of metal fasteners

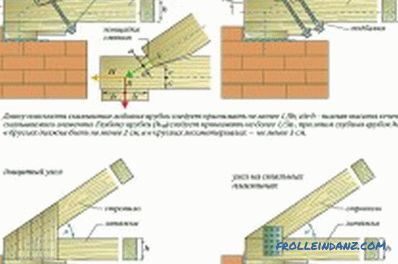

Recommendations for fixing the lower ends of the rafters to the building.

Depending on the roof construction, a certain method of joining trusses is selected. At the same time using different metal fasteners.

Metal brackets, bolts, plates, screws, steel brackets, wire ties are used as fasteners.

In the case of brackets when connecting the rafters to the power plate, it is not necessary to perform a tie-in on the rafter. Thanks to it the bearing capacity of rafters increases.

The brackets are made of galvanized steel with a thickness of 0.2 cm. Attach the brackets with anchor bolts, screws or nails.

Apply perforated durable fasteners to the fastener.

Ways of connecting rafters to mauerlat

If the construction of a building uses the simplest method of roof construction, the connection of rafters and mauerlat is performed in the same plane with the truss foot.

Methods for attaching rafters to the power plate.

Then the load of the roof elements has a point character. It is not distributed over all the bearing walls of the building using beams.

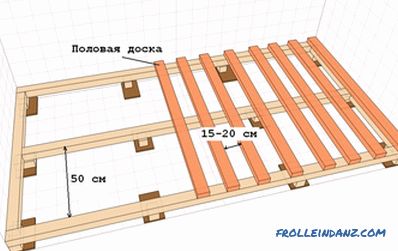

In the floor beams, which project 40 cm, special grooves are cut out at the ends, and boards are inserted into them.

For high-quality mounting of cross-beams, a string is used, which is pulled on the outermost beams.

Boards that are installed in the slots need to be attached to the beams with steel corners. In some cases, they are attached to the beams with wooden linings. This method of fasteners is not as durable as when using steel fasteners.

The installation of the boards in the ridge part is performed end-to-end. The end of each rafter is cut at an angle corresponding to the corner of the roof slope. To do this, make a template. Under the ridge of the board connect with two nails that hammer at an angle.

Ridge joints can be fastened with a steel plate or a strap made of wood, which is bolted. In the manufacture of ridge girder boards attached to the ridge beam.

The most commonly used overlap joint. At the same time rafter legs attach sides and fasten them with bolts.

Fastening the boards on a ridge girder

Connection of rafters by cutting in half-wood.

Usually the length of the boards is 6 m. If it is necessary to use boards of greater length, add timber. To bond the details of the design can be different.

Butt-to-cut installation is made of bars, the ends of which are cut at a right angle. Wood pads are hammered on the connection site on both sides. Fastening elements are placed in a checkerboard pattern. Instead of wooden plates, you can use metal plates.

The overlapping assembly is made of bars, the ends of which are cut at any angle. The length of the connection bars must be at least 1 m. Fasteners are placed in a checkerboard pattern. If bolts are used, then metal plate washers should be used so that the fasteners do not sink into the wood.

If the fasteners are made with bolts, metal plates, steel corners, then they are more durable than mounting nails.

When installing the roof system, which is the basis of the roof, it is necessary to adhere to the strict technology of work. The reliability of the roof and the duration of its use depend on the method of fastening.