One of the most important operations performed when replacing window blocks is the manufacture of slopes, the quality of the arrangement of which ultimately determines the appearance of the entire window as a whole. Today in construction practice there are three types of window slopes:

- plastered;

- plasterboard;

- plastic slopes.

Plastering slopes

Plastering slopes of the window

Plastering slopes of the window

This kind of slopes It refers to the old technique of facing window openings and is considered to be very impractical and inconvenient in execution. The disadvantages of such slopes include:

- poor thermal insulation properties;

- the possibility of condensation due to rapid temperature changes;

- high probability of plaster cracking due to contrasting operating conditions ;

In the manufacturing process, such slopes are plastered in several layers, after which they are necessarily coated with a primer and painted. Their production (taking into account compliance with all requirements on the topic “how to properly make a window slope”) will take, as we see, quite a lot of time; besides, only professionals can perform high-quality plastering work.

If you have chosen this type of slope, you should consider the following recommendations, mainly concerning preparatory procedures:

- when working, the frame should be closed with a protective material;

- it is advisable to reinforce the upper slope with a mesh netting;

- before starting the plastering, ideally even planks that serve as control surfaces should be nailed to the side slopes on both sides.

Plasterboard slopes

In comparison with plaster slopes, gypsum cardboard slopes are considered more durable and in the case of warming them with cotton wool can provide good thermal insulation for windows. But because of the increased sensitivity of drywall to moisture, you will hardly be able to obtain good waterproofing with it. Therefore, it is allowed to install such slopes only in rooms with a low humidity level.

Note that their production also requires a certain skill and ability to perform many auxiliary operations (plastering, priming, painting, etc.).

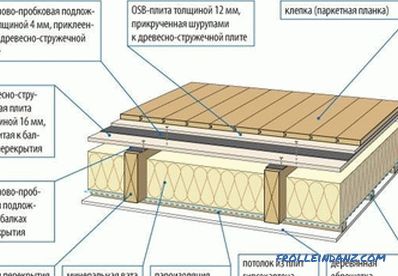

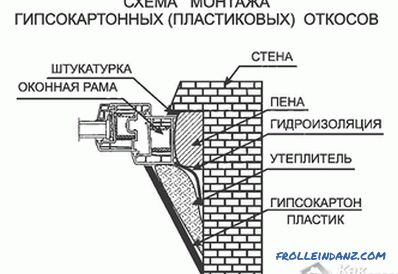

Installation scheme for plasterboard slopes

Installation scheme for plasterboard slopes

To make plasterboard slopes, the following is done:

- The profile corner is taken and cut into segments according to the size of the window block. Then these segments are attached along the edge of the window profile (along the entire perimeter of the block) with the help of screws, which will later be hidden under the drywall.

- After that, a drywall blank is cut (moisture-proof material is best suited for this purpose) to the width of the slope and to its entire height. Part of the slope on the side of the window is filled with mineral wool, and the inner edge with the cut face is attached directly to the corner. The second edge, facing the edge of the room, is glued to the slope with a special glue.

- The perforated corner is fastened to the corner part (from the side of the room) with the help of a sealant, after which the joint near the window is sealed and the entire surface of the slope is carefully puttied. After polishing, it is covered with a special primer (deep penetration) and painted on top with water-based paint.

Video

One of the ways to make plasterboard slopes:

Plastic slopes

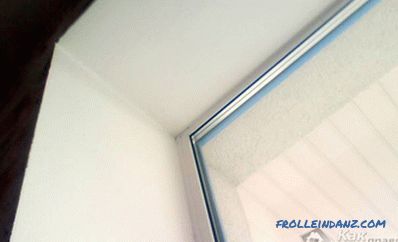

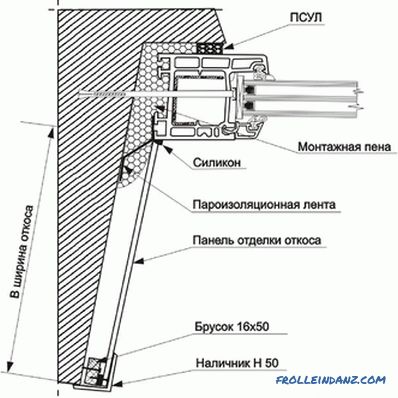

Installation scheme of plastic slopes

Installation scheme of plastic slopes

Demonstrate how to make a window slope most conveniently using the example of a plastic modification that is currently considered the most universal and practical. Slopes made of plastic are easy to clean and do not fade with time. As a heater in such constructions mineral wool is used, which provides the windows with excellent waterproofing properties and eliminates their fogging. Installation of plastic slopes is carried out in the following order:

- First of all, along the perimeter of the slopes, with the help of self-tapping screws (flush to the wall) wooden slats are filled, which serve as the basis for flexible plastic. To obtain high-quality slopes, the slats must be positioned strictly vertically, which is achieved with the help of a building level.

- Next, using a level, a vertical (left and right) and upper horizontal lines of the outer edge of the slopes are drawn with a pencil and the starting strip is filled with self-tapping screws. The groove of this starting strip will serve as the fastening of the plastic slope.

- Then, an F-shaped profile is mounted, which is first measured according to the height of the slope. This profile is attached to the wooden slats using a construction stapler.

- After that, it remains only to install plastic slopes with their simultaneous insulation. One edge of plastic is inserted into the starting strip, and the other (after laying mineral wool under it) is fixed in an F-shaped profile.To obtain high-quality joints plastic must be measured with high accuracy.

As a result of competently performed operations, you will be able to get a completely aesthetic and completely tight construction. To eliminate microscopic irregularities, it is recommended to wipe the joints of all parts with white silicone.

Video

You can see the process of making PVC slopes in detail in this video: