The stool is a fairly popular element of the interior. Especially it is needed in large quantities, when the owners like to receive a lot of guests. You can make stools with their own hands.

The stool is versatile and compact, which is why this type of furniture can be seen today in any living space.

But if this is the first time to do this work, then you should know a few points:

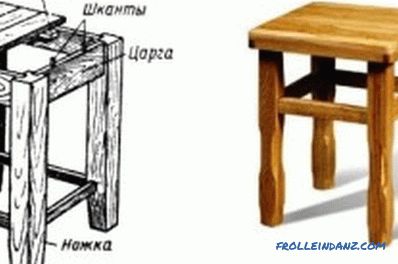

- The most reliable type of connection is a “tongue and groove”. But it should be used in the case when you already have skills in carpentry. It requires accuracy when cutting grooves, otherwise the design will not have durability, and during operation, wood fibers will create a creak.

- The stool is designed for permanent movements. Therefore, the material for its manufacture is required to select such that it does not quickly "disheveled". He should also hold fasteners well, such as screws, nails or screws.

Both of these points need to be considered before making a stool, especially if a novice takes on the job.

What to make a stool?

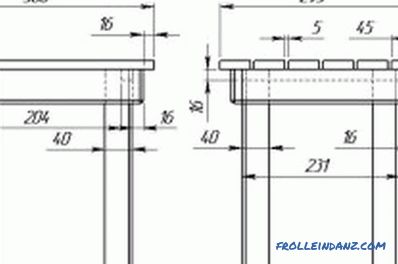

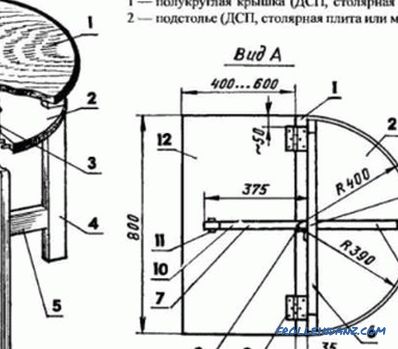

The drawing and dimensions of an ordinary stool.

Depending on the style of the interior, you can find chairs of absolutely any shape and material, even metal. For lovers of exclusive, you can pick up a stone or glass stool. Although the most popular and accessible material is still stools made of wood.

The simplest design of such a chair consists of a seat, 4 legs and connecting plates. You can make a stool using the following materials:

- 3x30 mm bar that will serve as legs;

- two boards (14.5x30 cm, thickness - 2-2.5 cm);

- plywood sheet (thickness 1.2 cm);

- glue;

- emery cloth;

- acrylic varnish;

- screws of size in 4 cm.

If there are such materials at hand, you can safely begin to make a stool.

Selection of the right tools

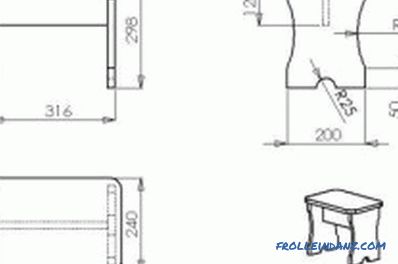

Drawing of a stool with solid legs.

Basically, the design of wooden stools is nothing complicated. The main thing - stock up on the right tool, namely:

- a fine-toothed hacksaw;

- a cross-head screwdriver;

- a drill;

- a construction meter and a corner;

- with a simple pencil;

- with a drill;

- with a brush under the varnish.

If there is an elementary knowledge of construction equipment, then one of the above elements can be replaced by an analogue. But a newbie is better to follow this list so that it is easier to carry out all the work.

Instructions and action plan on how to make a stool

- The very first stage is the preparation of the support, that is, the legs. To do this, the timber is cut into four equal lengths of 43 cm. Support for the “fifth point” will be made from the boards, so it is cut into two blanks 14.5 x 30 cm in size.

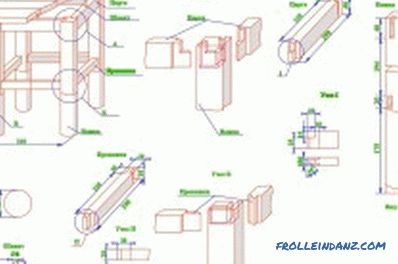

- Plywood will serve as a connecting strip. For this purpose, the sheet is cut into segments 10 by 27 cm. After that, a groove (1.2 x 5 cm) is cut at wide edges, while keeping the distance from the edge of 3 cm, equal to the thickness of the leg. The resulting elements are collected in a square, which will serve as a frame.

- Next, the plywood frame, the seat and the legs are joined.

Stool assembly scheme.

To do this, it is necessary to make holes in the appropriate places with a drill, where all the elements of the stool will be fixed with screws. To make the clutch more reliable, the joints can be opened with auxiliary glue. For this purpose, suitable and PVA. For wood stools, it will not be superfluous to work on a facet, or rather remove it. This will smooth the edges of the parts, due to which the product will have a more presentable appearance.

The tree has such a structure that during the carpentry work with it, barbs are formed on the surface. In order to grind the stool, sandpaper is used, and experts recommend doing it in two rounds. That is, first to work with coarse sandpaper, and then fine-grained walk on top. Grinding helps to eliminate not only burrs, but also to give the entire product a “aligned” look.

The final point is opening varnish. It is best if the varnish will be applied in two layers. But only the subsequent opening is carried out when the previous layer is completely dry.

When designing stools made of wood, one should also remember about personal safety. For example, shavings can get into the eyes or burrs under the skin. Therefore, you should think in advance about the means of protection: gloves, glasses, etc.

The second version of the design of the stool

We have described above how to make the simplest stool with your own hands. But there is another option for more interesting cross-shaped legs and a soft seat. That's about this model further and will be discussed.

To begin with, we prepare the working tools and materials:

The device of an ordinary stool.

- wooden beam with a cross section of 60 mm;

- rail (3x6 cm);

- plywood sheet (thickness 1.2-1.5 cm );

- foam material (minimum thickness 10 cm);

- seating fabric;

- nails, screws, construction buttons;

- circular saw and screwdriver;

- brush, stain;

- varnish for opening or painting;

- marker, pencil;

- measuring tape;

- body .

And again, the base of the legs is prepared first. To do this, 4 pieces, each 60 cm long, are made of timber. They are made cuts in 45 degrees. Such works are performed with the help of the vessel.

When the segments are ready, they must be crossed between each other in pairs, that is, mounted in the manner of the letter "X". For this purpose it is necessary to prepare grooves on each piece. The size of the depth of the notch should correspond to half the thickness of the initial bar itself. That is, if the thickness of the timber is 6 cm, then the groove is 3 cm. At the same time, it is necessary to control the legs to fasten tightly with each other and not to crawl beyond the 6 cm mark, that is, the thickness. Thus, you should get a pair of X-shaped structures.

For the stool to be stable, both crosses must be tightly fixed to each other.

For this you need a bar made from a piece of timber. The length of the strap should correspond to the size of the stool. In this case, it is 48 cm long. In order to fasten both crosses with a plank, screws are necessary. To make the product more presentable, small recesses are made under the fasteners. At the end of all the work, these notches will disappear under a special filler or with the help of special plastic hats.

It is necessary to fasten the legs and in the upper part of the cross. Two screws are used for each joint.

The last moment is the “hiding” of the screw heads. Also legs need to be varnished or painted in any other chosen color.

Practical recommendations

But what is the stool without a seat. In the first case, a variant of wooden stools with a hard-top seat was made. In this case, the design is made with a soft surface.

The seat will consist of a hard, and on top of - a soft base. For the lower case is just designed plywood. Its recommended thickness is not less than 12 mm, otherwise the design will be too fragile and will not be able to fulfill its intended purpose.

In this example, the base has dimensions of 40x60 cm. In general, this is the average size of wooden stools. This base is cut out of plywood using a circular saw. The appropriate size should have foam rubber. Still used cushioning material, which will fix the foam with plywood. So, it should have an area of 30% more than the base.

While covering the product, it is necessary to measure the height and width of the obtained seat. It should also be borne in mind that the fabric should be attached to the plywood, which means that it is necessary to make additional stock. Best of all, when the upholstery does not have wrinkles at the corners of the stool, it will last longer without a fray.

To lock the fabric, use the buttons. They can be fixed in two places: on the bottom and on the sides. If the buttons are the simplest, then they are used for the first attachment, but if there are decorative ones available, then they are best placed on the sides. Although for a more reliable fixation, both of these methods can be combined. To stool had a neat appearance, tight-fitting is carried out only when the fabric is stretched.

In fact, for the design of a stool, you can take absolutely any fabric or even a leather substitute. It all depends on the interior, the desire of the owner and his financial capabilities.

The last step in assembling such a stool is to join all the elements into one structure. With the help of screws, the seat is attached to the resulting cross-shaped legs.

As is clear, assembling a wooden stool with your own hands is simple. All the necessary materials and tools are easy enough to find at home or even borrow from a neighbor. And at the same time there is always the opportunity to accommodate all their guests at home, rather than running around the neighbors and asking them for spare chairs.

Didn't find the answer in the article? More information on the topic:

-

How to make furniture of your own quality

How to make furniture yourself. What are the materials, and what is their difference? Variants of the drawings, as well as a description of the manufacture of an example. What else do you need to know when deciding to do this kind of work?

-

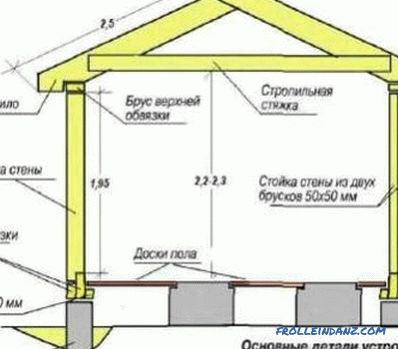

Wooden garage: do-it-yourself construction

It is quite possible to build a wooden garage with your own hands, and in a fairly short time.How to build a garage frame type: recommendations for the execution of works. Walls, floor, roof of the garage.