Working with bolts and screws has always been considered an important stage of repair. After all, the quality of such work directly affects the strength of fasteners. As a rule, a slow drill or screwdriver makes it much easier to work with screws. These are very useful tools that are powered by electricity and make it possible to easily and quickly twist and unscrew screws and other similar parts.

Screwdriver circuit.

Perhaps the most important element of a screwdriver is a bit. It represents a hexagon, which is screwed into one side by a screwdriver, and the other side is needed to engage the screws (it is a screwdriver). In this case, the working side, depending on the type of fasteners, can have different types.

3 basic rules for choosing bits for a screwdriver

To work with a screwdriver was easy and he served you for a long time, you need to be able to choose the right bits for it.

It is better to buy a set of basic types of bits for various mounts, because you will always have the necessary attachments at hand. Experts recommend having in their arsenal 5 types of bits, which are shown in the figure. But, in addition to species, it is also important to be able to navigate in what material these elements are made of.

Types of bits for the screwdriver.

So, when choosing bits for a screwdriver, you need to pay particular attention to some very important points. These include the material from which the bits are made, the presence of a protective coating on the work item, and the place where you are going to buy material.

- First of all, you need to choose a safe place to buy. If you need quite high-quality bits for a long term use, then it is better to give preference to special stores. Moreover, there all the goods will be certified, and you can also get a quality guarantee. To buy bits in the market at a cheap price is not desirable. The only exceptions are when you need bits one or two times.

- The next most important issue is the material from which the working part of the bit is made. As a rule, the best are 3 reliable alloy. It is an alloy of chromium and molybdenum, chromium and vanadium, as well as tungsten and molybdenum. But the bits of the steel should not be acquired - they will be erased very quickly, and the first time they will not be able to do the work with sufficient quality. Note also that in the bits of optimal quality of the above alloys made not only the work item, and the whole bit completely.

- It is also important to have a special protective coating on the instrument. If the bits are covered with titanium on top, then you may not even doubt the quality of the part. In terms of resistance to titanium, diamond and nickel are slightly inferior. Another protection option is tungsten-nickel alloy. In this case, tungsten will provide a high degree of strength, and nickel will maximally protect the metal from corrosion.

The choice of bits depending on the brand

The nozzle scheme for the screwdriver.

These were general basic tips for choosing the bits for the screwdriver. They should be guided in the first place. But it is also very important to know what the main brands of bits are and how they differ from each other. Today, there are three such brands.

These are bits of the type Torx hole, Pozidrive (Pz), Slot (Sl). These three brands have proven to be the most reliable and good. Therefore, it is advisable to consider them in more detail.

Bits for a screw driver of the type Sl

Marking of the screwdriver bits.

So, the sl bits are a slotted screwdriver at the working end. At the same time, depending on what type of mounting such a bit is chosen, the width of the slot can fluctuate. Usually a digit is written on the bit near the Sl marking, which will indicate the specific slot width in millimeters. In today's market, the width ranges from the smallest (with marking 0) to the maximum (with marking 7).

There are bits of this type also in length. In this case, it is best to choose a bit with a special limiter that will not allow, during operation, to tighten the screw deeper than necessary. It is very convenient when working with drywall constructions and when assembling some elements of furniture.

But bits of this type with a limiter are not always advisable to use. For example, when you need to ensure the most reliable grip with the mount due to the strong and fast torque, these bits should not be used. In this case, it is better to use the bits without a limiter.

Bits for a Pz screwdriver

A bit for a Pz screwdriver.

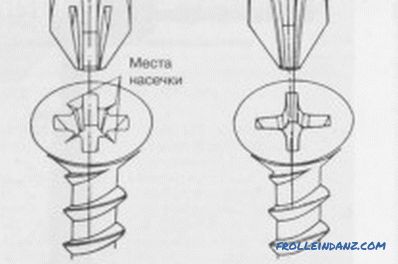

The next mark is the Pz type bits. It is possible to consider such parts universal, since they make it possible to work with universal countersunk screws, with screws with medium pitch, and even with all types of Pozi fasteners.The working part of such bits is a kind of cross with 4 main and 4 additional edges ("double cross"). Therefore, the tool is very well suited for cross mounts and mounts with a fairly large area.

The size of the screws varies from 2.5 to 4 mm. In this case, these devices allow you to work without rusted or damaged bolts, as well as with very dense materials. Such characteristics are provided due to the high degree of torque. It should be noted that this type of bits are ideal for screwing and unscrewing screws and bolts at different angles that are different from 90 degrees.

Torx nozzles

Torx nozzles.

Another good type is the Torx bits. In fact, this type of element is almost always the most expensive and powerful. After all, Torx provides the highest degree of reliability of coupling with the heads of anchors, screws and bolts. It is very important that slipping and shifting are practically excluded. They are quite convenient to use when considerable effort is needed for fasteners.

Again, it is customary to put a number from 8 to 40 (in millimeters) near the marking, which will indicate the size of the working part of the bit. As a rule, in some particularly expensive types there is also a hole inside with its own dimensions of the working part.

Most often, these bits are advisable to use in the production of works with spare parts for cars and home appliances. Indeed, in this version there is the widest range of selection of the size of the working part. In addition, there are even bits of sizes smaller than 8. Only here in the screwdriver it is better not to use them. And it is better to wear a bit on the universal screwdriver.

Selection parameters by the generally accepted characteristic

Types of bits for the screwdriver.

Besides all this, it is accepted to divide all kinds of bits into basic, combined and special. The main bits usually have a cross-shaped work element, which provides a large area of adhesion to the screw head. But there are bits of such a plan with a flat working element that looks like a regular screwdriver. But here the obligatory condition of the maximum grip area should be observed.

Combined bits usually have a working part from two ends. At the same time, these two parts must be different from each other, either by type of fastener, or by size. When working, the necessary part remains, but the unnecessary part is unscrewed, and this place of the bit is attached to the screwdriver.

It is quite another thing - special bits. They are intended, as a rule, for a fairly narrow range of applications. Such bits are divided into two main types: bits with detents-stops and bits with special springs. At the same time, the bits based on the limiters make it possible to manually adjust the screwing depth independently. But the springs allow you to optimally twist or unscrew the screws or screws at steep corners, and also in those places where it is hard enough to penetrate.

So, the main types of bits and tips for choosing them were considered. Whatever materials you choose, the main thing is that they are of high quality. Only then can you achieve maximum reliability of fastening, wherever it is carried out.

Didn't find the answer in the article? More information on the topic:

-

How to choose the right drill driver?

How to choose a power screwdriver so that it works long and reliably. What are the batteries for the specified tool, their main advantages and disadvantages.