Modern technologies somehow completely imperceptibly brought one more innovation to our life, previously available mainly for the military and geologists (lovers of hard-to-reach places), a screw foundation. At the same time, the relative simplicity and speed of creating such a construction using special piles gradually "moves" aside the ribbon and columnar foundations we are used to.

But whether such a foundation really is a universal solution for building a solid and durable foundation for a house. In the article we will explain how to do it, we will give detailed step by step instructions,

Screw pile

Screw piles

Screw piles

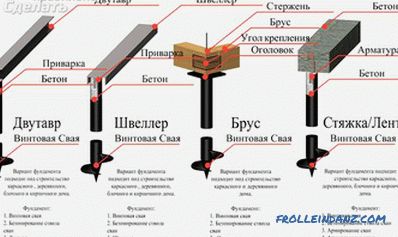

This is a metal pipe (treated with a special compound that slows down the corrosion process), the blade is welded to the lower pointed end. Such a pile is screwed (screwed) into the ground (like a screw into wood), practically without damaging it (only compacting it by immersing the pipe) and, therefore, absolutely not reducing its carrying capacity.

These piles are available in several types:

- with a screw blade (used on soils with poor bearing capacity) or imitation of thread cutting for the most part of the pile length (such piles are usually used in northern areas where it is required to not particularly disturb the permafrost when building the foundation for buildings and structures);

- with different pipe diameter - the larger the diameter, the larger the weight of the building is able to perceive the pile (without its deformation), but do not forget that the thicker piles (diameter greater than 108 mm) akrutit hand will not succeed;

- with a different diameter of the blade - for lower strength and water saturated soils blade diameter is larger than for dry soils and dense.

And, of course, the type and shape of the pile also depends on the manufacturer, which produces it.

What a screw foundation looks like

What a screw foundation looks like

A screw foundation looks like this:

- in the corners and at the intersection of the inner walls, as well as along the length of the wall of the structure, piles are screwed into the ground (the pile height varies from 1 to 3 meters);

- all piles are cut to the same level and fastened with metal , or wooden beams to create a single rigid structure - grillage;

- there is a free ventilated space between the ground level and the bottom of the building (grillage).

Strengths and weaknesses of

Difficulties for the installation of screw piles

Difficulties for the installation of screw piles

fairly simple design. However, “pitfalls” are waiting for you here:

- piles should be chosen strictly in accordance with the calculation made by the designer on the basis of hydrogeological surveys on your land plot, the depth of soil freezing and the weight of the future building. snow cover applied to a building in winter (otherwise you risk either overpaying for piles of greater length or diameter, or to get a completely unstable structure that you will “lead” in a year);

- , depending on the soil, you can screw the piles manually pretty hard (even if 4-5 people take part in this process);

- the presence of trees, tall shrubs, fences or other buildings in the immediate vicinity of the foundation site creates problems for manual piling;

- not all firms do their job efficiently, respecting technology.

Installed pile

Installed pile

However, the screw foundation has advantages:

- no bulk excavation work is required;

- can be installed on any terrain, without prior leveling the terrain;

- piling works are carried out at almost any time of the year.

Basics can be arranged on any soils with the exception of rocky ones, since the rock itself is an excellent solid base (for a band or columnar one).

Preparatory work

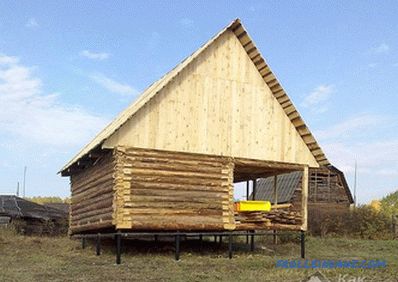

Bath on screw piles

Bath on screw piles

It is quite possible to make a foundation under small building (garage, gazebo, veranda, one-story wooden frame house):

- the pile can be welded by yourself using the drawings posted on the Internet, or you can weld the piles in the image (for this you will need to order the calculation, and then purchase one recommended pile at the factory);

- also independently (with the help of friends) you can load the piles into the ground, being guided when arranging them with available drawings and perform and grillage.

For a screw foundation, it is not worth saving on material. Piles should be made only from new pipes of the required thickness, while they should be thoroughly cleaned of rust and covered with a protective compound.Particular attention is paid to the quality of the welding joint at the point of attachment of the blade, since on sufficiently dense soils, the seam may burst without sustaining the load applied to the pile.

To facilitate the process of screwing in the pile in its upper part (which you then cut off with a “grinder”), you must make two holes - you will be able to put bars in them with which the pile is screwed into the ground.

Marking of the screw foundation

Marking of the screw foundation

Marking of the section

Installation should be carried out as accurately and competently as possible. The maximum permissible error in the vertical section and between the piles is no more than 2 cm. Otherwise, in the future you may be faced with the need to repair the grillage due to its sagging. And this, in turn, will lead to a violation of the load-bearing wall and even to the building skew.

The basis on the screw piles should be located so that the load on it and on the ground is distributed as evenly as possible. So take a plan of the house and break it into rectangles. On their sides and diagonals should be placed blocks of supports, taking into account the required distance between them. With all this, each pile should be in the center of all the supporting beams at home.

Marking the area for installing piles

Marking the area for installing piles

So, divide the house plan into rectangles, having previously determined the size of each of them. So, you can calculate the number of piles and distribute them over the area so as to evenly distribute the load on the foundation. After the completion of the planning, transfer the markings from the paper to the surface of the earth, on which the house will stand on piles. In the installation points of piles hammer in pegs.

Work steps

Work is performed in the following sequence:

- Dig a lead hole for each pile (just remove the top layer of earth with grass in this place), depth which should not exceed 10-15 cm, and the width should be 2-3 cm larger than the blade diameter. Some professionals advise not to dig the leader hole, which increases the stability of the pile, but at the same time increases the efforts to screw it into the ground by hand. You can not dig deep holes and just install piles in them, deepening them just a few tens of centimeters. One of the necessary conditions for high-quality immersion of screw piles is the intact soil around it, which allows the pile to transfer the load from the structure not only to the lower end and the blade, but also to its entire lateral surface.

Self-installation of screw piles

Self-installation of screw piles

- Install the pile and together with the assistants with Using a special rod, screw it into the ground, constantly checking the verticality of its position. The pile should sink into the ground below the level of soil freezing in winter.

- Align the top of all the piles to the same level (mark it on each pile using a level), cut off the excess with a grinder.

- Pour concrete into the pile (this will increase its strength and reduce the rate of metal corrosion).

- Weld a metal plate (not less than 8-10 mm thick) protruding beyond the pile boundary several centimeters from all sides to the top of each pile.

- Perform a grillage by attaching the beams to the plate using welding or bolts.

Screw foundation of the screw foundation

Screw foundation of the screw foundation

Video

Learn all about arranging screw foundation, watching the following video: