It used to be very prestigious to have a wooden floor at home. Of course, after a certain time they lose their attractiveness, and, accordingly, the owners come to the conclusion to replace them. In this case, the screed is fitted on a wooden floor. The main thing is not to remove the tree, because the whole process will be performed on top of it.

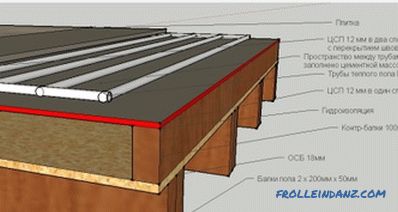

"Pie" screed on a wooden floor.

But while laying the tie on the wooden floor, you should be prepared for some problems. Firstly, if such repairs take place in a private house, then we must remember that there are utilities (plumbing, sewage, heating). Secondly, a floor screed with your own hands implies raising its level by several centimeters, which means that the doors that previously opened inwards must be shortened.

How to make a tie on a wooden floor?

You can lay the tie on a wooden floor only if its boards are not rotten or cracked.

Before embarking on such work, it is necessary to establish the quality of the floor covering. Wood tends to crack and rot, so there is a risk that after laying the screed the entire floor may collapse due to the large weight of the cement mortar. The wooden floor is self-made using cement mixtures with a high drying rate. With their help, the surface is fairly easy to align. Experts recommend additional use of reinforced fiber to ensure durability.

Tools and materials needed for the work on the coupler

Each stage of this process implies the presence of one or the other tool, as well as all the materials that will be involved. Therefore, you need to take care to have at hand:

For wooden floor screed, you will need fiberglass mesh.

- milling cutter;

- parquet putty;

- primer;

- vacuum cleaner;

- fiberglass mesh;

- pneumatic stapler with staples;

- drill with a whisk;

- steel spatulas;

- Bulgarian;

- construction level;

- wooden boards for the size of baseboards;

- elastic material for seams.

The steps of holding a wooden floor with your own hands

Looking ahead, I would like to note that the reliability of the floor can be assessed only after 28 days of drying the concrete mix. Only then can you assess the level of compression and deformation of the screed.

Preparation of a wooden floor

If the boards have a peeling surface or remnants of a previous cement-sand screed, they are removed by grinding or milling. It is also necessary to get rid of old autopsies and accumulated fat. In case of detection of irregularities greater than 1 cm, they are smoothed using special cement mixtures. If you had to carry out such a "fine" alignment, then the main tie will have to be done only after the end of the previous corrections.

Carry out filling gaps in the wooden floor.

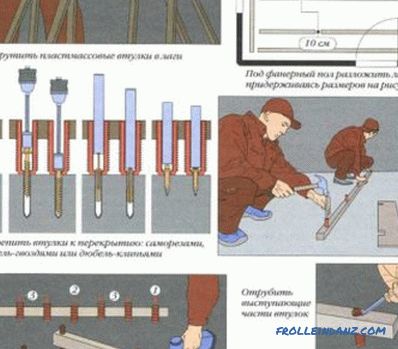

If rotten boards are found, they should be immediately replaced with new ones. The same goes for sagging. The wooden floor must be securely attached to the logs. It is necessary to seal up the gaps between the floorboards, for which we use parquet putty. It can be made independently, the main thing - to observe a proportion: sawdust and oil paint - 4: 1. Do not use water-soluble putty. It is necessary to dismantle the baseboards, replacing them with temporary thin planks. All the cracks formed are filled with putty. After you were able to make a wooden floor screed, the planks are removed, and those gaps that were previously filled up will serve as additional ventilation, which is designed to prevent rotting of the wood part.

Primer coating

After the floor has been sanded and the chips have been removed (using a vacuum cleaner), the surface is coated with a primer. This is done in order to increase grip and prevent the formation of air bubbles. In addition, there is water in the cement screed, and due to the soil opening the moisture is not absorbed into the base. But it should be remembered that the soil dispersion is applied only on a perfectly dry floor, otherwise it will not fulfill its purpose.

Base reinforcement

To accomplish this step, glass fiber mesh is taken and fixed to a wooden floor with a stapler. You should know that this grid is not driven directly into the floor, as it should be located approximately in the middle of the cement screed or in its lower layers.

Mix preparation

The use of a stationary concrete mixer will reduce the time required to work on mixing cement for screed.

The proportion of the mixture looks like this: for 25 kg bag, 6.5 liters of water are used.If necessary, you can add another 0.5 liters of liquid, but no more, since the floor solution will have a liquid consistency with your own hands, which greatly complicates the task and degrades the quality. A large amount of liquid leads to the fact that the mixture begins to exfoliate. For mixing proportions, a drill with a whisk is taken. The process is carried out for at least 1 minute until a homogeneous mass is formed. All work should be carefully considered so that the solution does not thicken and the instruments do not deteriorate if it hardens on them. If the type of tool allows, it can be placed in a container with water, after which it will be easy to clean it of residues.

The resulting solution must be used within 15 minutes after preparation.

When mixing, it is necessary to take into account temperature indicators. So, the temperature of the solution should be at least + 10 ° C. If the room where the screed is held on the wooden floor is cold, then warm water should be used (maximum + 35 ° C) while mixing the solution.

Wood flooring with a screed

It is applied only after the flooring is completely prepared together with the mortar itself. The main condition for a quality floor do it yourself at this stage is fast work. Using a steel spatula, the solution is applied to the floor. After 4 hours, the first neat steps can be taken. Sometimes there is a need for polishing surfaces, which is carried out after 6 hours of drying. The main thing - do not forget to dismantle the boards, which replaced the baseboards.

Of course, initially, in order to facilitate your work, you can create a marking on the walls with the help of a building level. Thus, you can navigate to what level is poured tie.

Working with expansion joints

This issue is dealt with after the final drying of the screed. In order to give the slots a geometrically correct shape, it is necessary to use a grinder, after which they are filled with a special elastic material.

Calculation of the mixture for the room

In order to properly procure all the materials necessary for the mixture, there is a calculation formula: 1.5 kg of the mixture per 1 m². In this case, the mixture will have a thickness of 1 mm. The screed itself should not be less than 1 cm on the wooden floor.

Still, experts recommend adding a plasticizer to the solution, and as an alternative, you can take regular laundry detergent (one handful of powder goes to 100 liters). Such an additive will help to gain additional strength and increase the water resistance of the screed. It should be noted that the working tool must be cleaned with water immediately after use. Thus, there will be no difficulty with it after the mixture has hardened. In the opposite case, the cleaning will have to be carried out by mechanical means.

It is very important for such a process to allow the coating to dry properly. Builders often use a method such as wetting with water. This helps not to crack the solution while it is drying. To do this, 2-3 times throughout the day, until the screed will dry, the surface should be moistened with plain water.

If during all stages the technology is adhered to, then the coupler is sure to be of high quality and reliable, and it can be used under any chosen floor covering.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building with serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.