One of the most important elements of the house is its roof, which protects the house from various atmospheric phenomena of nature and keeps it warm. Therefore, the roof of the house should be reliable and durable. The basis of a solid roof is its frame - truss system. The strength of the roof and, ultimately, the durability of the building itself depend on the correctly designed and correctly assembled structure of the rafter frame.

Roof made of metal tiles.

The rafter frame structure depends on the type of roofing and roof loads. The load on the rafters are permanent and temporary.

Constant loads are:

- the weight of the roof covering;

- the weight of insulation materials;

- the weight of finishing materials (when creating the attic floor);

- the weight of the truss frame and crates.

Temporary loads include:

-

The location of the tightening in the truss system.

wind pressure;

- snow weight;

- moisture weight when rain falls;

- loads during repair work .

During the design of the frame, its type is primarily determined (depending on the method of installation of the rafters). Rafters can be trailing, nested or combined. The number of rafters, the distance between them and their section, depends on the type of attic. It can be attic or non-residential.

Coniferous wood is usually used for making rafters. The moisture content of the material should not exceed 20%. Timber used for the construction of the truss system should not have rot and blue.

The material of rafters, lathing and counterbriquettes is treated with antiseptic and flame retardants.

Preparatory stage

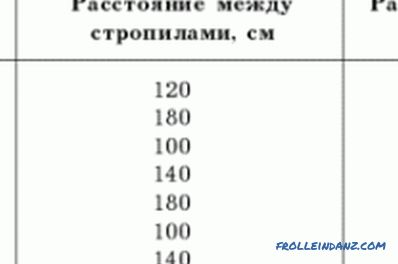

Table for calculating the length of the rafters, the pitch between them and the cross-section of the bar.

The creation of a roof begins with the selection of the type of roof and the material of the roof. In individual housing the most popular roof of the metal. This type of roof is light, durable, strong, has an attractive appearance, is quite simple to install and inexpensive. Metal tiles are much lighter than ceramic tiles (1 square meter of ceramics is about 35 kg heavier than metal tiles).

Then you need to calculate the number of rafters and the step of their installation. When building private houses, the step between the rafters is set from 0.6 to 1.0 m.

To calculate the required number of rafters, you need:

- Measure the length of the roof slope. Then this size is required to be divided by the step length between the rafters.

- Add the unit to the resulting value and then round the resulting amount to an integer. According to this method, the number of truss legs for the roof slope is calculated.

- Then it is necessary to divide the length of the slope by the number of rafters and determine their installation axes.

- The rafters pitch depends on the type of roofing and the slope of the roof slope.

Calculation example: Let the slope be 18 meters and the step size be 0.8. Hence, 18: 0.8 + 1 = 23.5 = 24 rafters are required to construct a roof frame.

Installation of rafters

Rafter systems for different types of roofing have slight differences. They mainly depend on the weight and size of the coating sheets. The following tools and materials will be needed to set up the truss system:

The optimal pitch and cross section of the rafter under the metal tile.

- chainsaw;

- wood saw;

- carpenter ax;

- chisel;

- construction stapler;

- construction level and plumb;

- hammer;

- nails;

- self-tapping screws;

- metal rafters;

- electric drill;

- screwdriver;

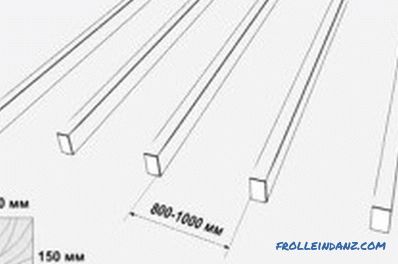

- bar 150x150 mm (for Mauerlat);

- board 50x150 mm (for rafters);

- board 25x100 mm ( for battens);

- 30x50 mm bar (on the counter lattice).

Having made the necessary calculations, preparing the required material and tools, proceed to the assembly of the roof system under the metal tile. The order of work is as follows:

- First of all, it is installed from the mowerlat bar. This is the base of the roof, which assumes the main load from the rafter legs. The beam is laid and fastened (with anchor bolts) along the perimeter of the walls, on a prepared reinforcement belt. Under the beam fit waterproofing (strip of roofing material).

- On a flat surface (according to the sketches) a template is made from flat boards, according to which truss trusses are made. In the skate they are attached with metal plates or nails.

- On the mauerlate, at the calculated distances, grooves are made to install the rafter legs.

- Prepared farms are raised and installed on the timber. First install and secure the extreme blocks. Vertical installation is checked by a plumb.

- Between the farms, the cord is stretched and the rest of the elements are mounted on it.The rafter legs are attached to the mauerlat with metal corners and self-tapping screws.

- Horizontal jumpers are installed near the upper part.

- At the bottom of the rafter legs, an eaves overhang is created with a projection of at least 50 cm from the wall. To do this, a wall or board is attached to the wall at the level of the rafters. A short board (fillet) is attached to the end of the truss foot with one end, the second end is attached to the wall.

This completes the installation process for the roof frame, then it is required to prepare it for laying the roof.

Preparing the frame for roof laying

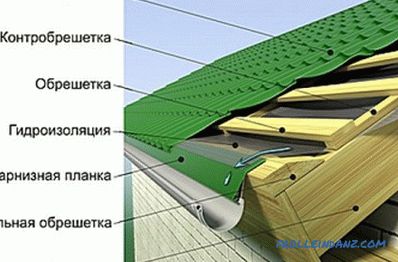

The rafter system on which the metal tile is laid is prepared as follows:

- A hydroprotective film is placed under the metal tile and fixed with a stapler. The film is installed with a sag of about 20 mm and an overlap of at least 150 mm. The edges of the paintings are glued with adhesive tape.

- On top of the installed film on the rafters, there is a counter grille (30x50 mm bars), which serves to create a roof ventilation gap.

- The crate is mounted on the counter grill (board 100x25 mm). The first bottom batten should be twice as thick as the next. The pitch of the batten is from 350 to 450 mm.

- The drain system fittings are installed on the prepared frame.

The installation of the truss system is prepared for laying the covering of metal tile.

If you have certain building skills and two assistants, you can make a strong framework for the roof yourself.

Didn't find the answer in the article? More information on the topic:

-

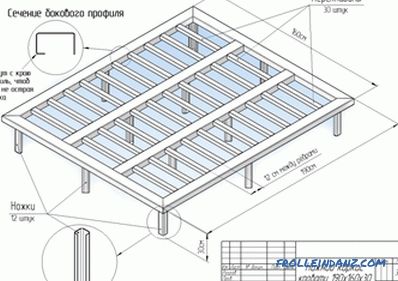

Quality furniture from shields with your own hands

Furniture from the boards with their own hands. Preparatory work. Full production of a bed from the first to the last step. The time after which you can begin operation.