Modern ways of processing plywood and wood allow you to create exclusive designs that amaze with their beauty and originality. Laser cutting of plywood has opened up the possibility of making very complex design products. It can be various lattices for decorating window openings, doors, inserts in furniture facades, suspended ceiling elements, internal partitions. Such products from plywood will harmoniously look both at home and in the interior of hotels, restaurants, bars, shops, clubs.

Laser cutting of plywood of different wood species differs in terms of the temperature of the beam and the degree of inflation.

Features of laser processing of plywood

Cutting plywood with a laser is among the most modern methods of processing sheet materials. Unlike traditional cutting with a manual or electric jigsaw, laser cutting of plywood allows you to achieve the minimum consumption of material, to perform the most complex shapes and patterns, jewelry detailing. This was made possible due to the very small thickness of the laser beam, which is a fraction of a millimeter, as well as the use of computer-controlled machine tools.

Advantages of plywood with laser:

Advantages of plywood with laser: the edges of the cut are very neat and smooth, no special physical effort is required.

- The high-energy beam acts like a point on the surface, carrying out contactless processing. Due to the powerful temperature increase at the point of contact between the wood and the beam, the material evaporates, resulting in a seam 0.01 mm wide.

- The edges of the cut are very neat, which is very important for cutting openwork small parts and engraving. Through the high-temperature effect, the edges of the cuts are slightly darker.

- In order to cut plywood, no physical effort is required.

- You can make absolutely any drawing or engraving - for this it is enough to have a sketch of the image in digital form.

- The quality of laser cutting depends on the wood from which plywood is made. As a rule, the deresined material from coniferous wood is best cut.

With the help of laser cutting you can:

- cutting of various blanks of different sizes from sheet material;

- souvenirs and gifts;

- decoration elements for facades and interiors;

- presentation and advertising materials;

- different patterns and patterns.

Equipment for the processing of plywood with a laser

Laser cutting is carried out using special machine tools with programmed control, the design of which uses gas lasers.

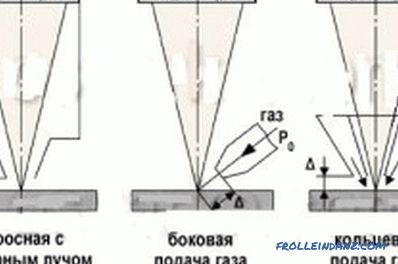

Auxiliary gas supply schemes for the laser cutting zone.

A person does not actually participate in the processing - it is fully automated. All you need to do is copy the selected pattern to the memory card, install it in the computer control unit of the machine and wait until the machine cuts out the specified contours. This procedure is very quick and waste-free.

To improve the quality of processing of wood sheet materials, in addition to machine tools, chillers and blowing systems can be used. Chillers are used for additional cooling of the flask with gas. They consist of a water pump and a refrigerant (freon), which does not allow the water circulating in the chiller to heat up. Pulling and blowing systems will help remove combustion products and subsequent cooling from the blanks. This reduces the degree of charring (darkening) of the cut edge.

Self-made machines, which can be used to perform laser cutting of plywood, are ineffective. Made in artisanal conditions, they can not provide the required laser power, high-quality cooling and power, perfect mechanical adjustment of all elements of the machine.

Laser cutting of plywood ensures maximum transfer accuracy of the original pattern. The elegant details of plywood are able to decorate even a very simple interior, giving it a touch of romance and sophistication. If necessary, they can be used to hide defects, radiators or other utilities. Depending on the cut-out pattern, such lattices can be almost opaque, which does not interfere with high-quality heating and ventilation of rooms.

Didn't find the answer in the article? More information on the topic:

-

How to choose the bits

for the screwdriverBits for the screwdriver: how to choose high-quality nozzles. 3 rules on the choice of bits. The choice of bits depending on the brands: nozzles of types Sl, Pz, Torx. Selection parameters according to generally accepted characteristics.