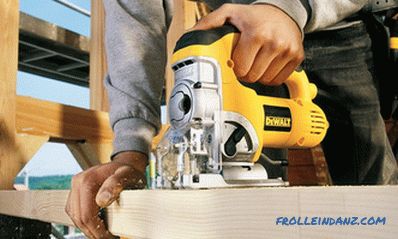

In this material we will describe how to use a jigsaw, how to properly cut various materials and sawing out shaped elements. You will learn about the safety rules when working with the tool, the intricacies of its maintenance, frequent breakdowns and how to avoid them.

Preparing the tool for work and additional tools

The Jigsaw is a kind of universal device that in some cases can replace a number of tools. Before starting work, it is necessary to carry out an external inspection of the instrument: make sure that the power cable is intact, check the electrical connection.

It is also important to choose the cutting blade correctly - for each material undergoing cutting, its requirements. The markings applied to the material should be clear and well visible. You can use the laser guide if it is included in the jigsaw. However, experienced craftsmen, for a more accurate cut, are advised to focus on the marks applied to the sole. All work is best done on the saw table - this item can be purchased at the store, or arrange it yourself.

A number of manufacturers produce additional devices designed to assist in the performance of various operations. The following extras will be a good help:

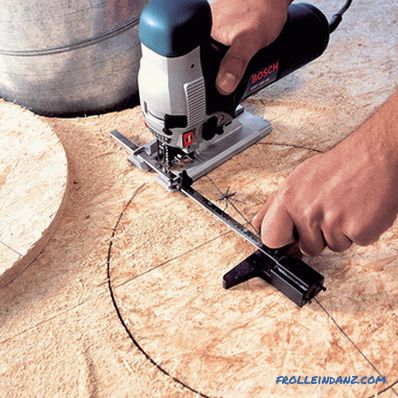

# 1. Parallel stop-compass - useful for cutting circles.

# 2. Parallel stop - for straight cut.

# 3. Guide rail - simplifies cutting in a straight line.

# 4. Removable pad for the support block - can be made of plastic or metal and is used to increase the jigsaw slip on the surface of the processed material.

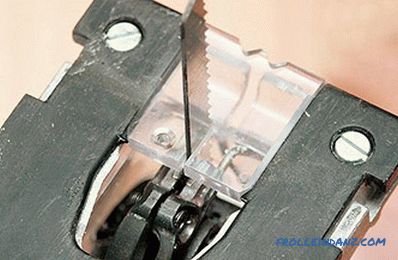

# 5. Anti-splinter liner - used to reduce the likelihood of chipping during work, especially relevant when sawing laminated lumber.

Having studied how to use the jigsaw correctly, you can proceed directly to the cut. The choice of the file and mode of operation plays an important role in the process of sawing the material and operating the tool. With an incorrectly chosen mode of operation, the jigsaw can break. Therefore, do not neglect the recommendations described below.

How to cut a tree

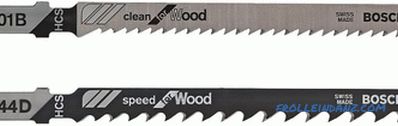

Select the file . Cutting of wood species is performed with standard files with upward-pointing teeth of medium size with tooth pitch from 2.5 to 4 mm. The length of the file is selected in accordance with the thickness of the workpiece.

Travel frequency . The stroke frequency is set to maximum. This indicator should be reduced only when the fabric is prone to overheating, or discomfort is felt in the process.

Pendulum Turn . To increase the cutting speed, it is necessary to turn on the swing wheel. It adversely affects the quality of the kerf, so it should be used when fast work is important, and the quality of the kerf is not particularly important.

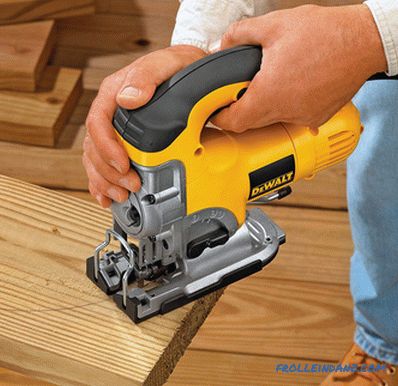

The cutting process . Work should be on the back of the material to avoid damage to the product. Before cutting the workpiece must be marked. When cutting, the tool must be pressed flat against the surface and guided smoothly. It is not necessary to push him forward much, because as he cuts, he moves ahead in the material, especially when the pendulum mechanism is turned on.

How to saw chipboard, laminate

Next, we will look at how to cut chipboard exactly with an electric jigsaw to avoid damage to the laminated front surface.

File selection . Experts recommend using a reverse cut file. However, in the course of work, there may be a feeling of discomfort due to increased vibration, but the quality of the cut will not suffer. If the sawing is done with regular sawing, the work is carried out on the back side of the material being processed.

Travel frequency . The stroke frequency must be set to the maximum.

Pendulum mechanism . To avoid chipping the pendulum mechanism must be turned off.

The cutting process . The tool must be pressed tightly to the surface of the material, while it must be guided smoothly without strong pressure.

Chips appear on the part of the material that is facing the tool. Therefore, if the cut is made by sawing with ordinary teeth, then you can determine the front side of the product in advance by making a cut on the back side.

In addition, an antiskol insert can be used to make cuts in a chipboard or laminate. This is a small detail with a kerf, which is inserted into special guides on the sole.The most ideal liner is the one in which the cut exactly matches the thickness of the saw blade. Therefore, some manufacturers complete with jigsaw supply several such liners. At the same time, I drank it in each of them myself. Then you can start sawing chipboard.

How to cut metal

Select the file . For cutting metal surfaces used files with a small tooth - a tooth pitch of 1 - 2 mm. Visually, such a file resembles a hacksaw blade for metal and can be used to cut other materials in order to increase the cleanliness of the cut.

Travel frequency . Cutting speed must be set as low as possible.

Pendulum mechanism . Pendulum swing completely off.

The cutting process . The tool for the workpiece must be moved slowly without pressure. The sheet of tin must be firmly fixed in advance by positioning it so that the line is cut as close as possible to the support.

If it is necessary to make a curved cut in thin tin and position the workpiece so that the cut line is not close to the support, it must be placed between two sheets of hardboard or hardboard. All markings are applied to the top sheet of fiberboard. This will prevent the formation of a burr.

It is also recommended to take short breaks in work and use additional sources of cooling to avoid overheating the file.

How to cut plastic

File selection . It is better to use a cloth with a small tooth, the same as for metal. This will improve the overall quality of work.

The jigsaw settings are set individually, depending on the type of plastic.

Pendulum Turn . To obtain an even cut, the pendulum stroke is set to the minimum position, or completely switched off.

Stroke frequency . Speed - no more than 40% of the maximum.

How to cut a tile

Select the file . For work on this material applies a special cloth, without teeth. Abrasive materials are applied to the surface of such files. Cutting tile or ceramic tile is rarely used, because the consumption of cloths in this case is too large.

Pendulum Turn . Pendulum move off.

Stroke frequency . Works are carried out at the minimum set speed.

The jigsaw is ideal for cutting short curved elements into a tile.

Features of cutting out round and oval elements

In this section, we will discuss how to properly cut an electric jigsaw round or oval elements. First you need to put a markup on the material. In most cases, a hole is drilled in the workpiece from which the product will be cut. The diameter of the drill should slightly exceed the width of the blade. For cutting curvilinear elements it is necessary to take a narrow file intended for such works.

The jigsaw is output to the desired path slowly. If you want to cut a circle of the correct form, you can use an additional device - krugorezom. To do this, it is necessary to determine the center of the circle and fix the stop-compass there, to make cutting.

For such work it is better to choose a narrow canvas. In the process of cutting, you need to focus on the position of the blade, since the elements that help in the implementation of a straight cut (fly guides, lasers), in this case will only knock down the direction.

In some cases, you can do without drilling a hole in the workpiece. To do this, the tool is installed at the edge of the sole behind the marking line. The jigsaw turns on, and with careful movements, bends down until it touches the working surface. The angle increases until the workpiece has been cut through. After that the tool stops, the file is taken out and established in standard working position. The exit to the marking is carried out by the method of gradual rounding of the cut line. Any effort on the instrument should be avoided.

For cutting out non-standard figures or patterns, the jigsaw is installed with the help of special fasteners or a saw table in a stationary state, nailing up. In this case, you will have to wield not a jigsaw, but the workpiece itself, moving it in accordance with the marking. This cutting method provides a maximum overview of the work process, adherence to the cutting line, control over the workpiece. Tool settings are set according to the material being processed.

Features of cutting out straight elements

Despite the fact that this type of work is one of the most common, lack of experience can cause difficulties with exactly Saw a jigsaw any element. It is recommended to opt for a file with a wide blade designed for straight cutting, in order to better maintain the marking line. For a smooth cut, an important role is played by the “smooth start” function. The tool in this case begins to gain momentum gradually, so that the jigsaw is better controlled at the initial stage of cutting.

In the course of work, you should not make excessive efforts to move the jigsaw forward, otherwise it will lead to the failure of the file or tool mechanisms. Worn blade should be replaced immediately, because the dull file causes an increased load on the electric drive. Sawed billet must be securely fastened.

To perform straight cuts, you can use a parallel stop or guide rail.

Sawing with the guide bar

First, the workpiece must be marked out. Thereafter? having installed the jigsaw in a special shoe, and then the shoe into the tire, the tool is positioned along the cutting line.

By setting the tool file along the cutting line, the guide bar is attached.

The tool is put into operation and run along the tire. It depends on the operator a little. Much more on the quality of the cut will affect the quality of the file and the jigsaw itself.

There are tires with clamps that allow you to make both straight cuts and cuts at an angle.

Sawing with a parallel stop

A parallel stop often comes complete with a jigsaw, but regardless of this, almost all models have a slot in the base for attaching a parallel stop bar.

You can make a high-quality cut with the help of this device only in the following cases:

- Reference plane along which it will move Shoe must be flat and parallel.

- The jigsaw must be of high quality and resistant to distraction.

- The parallel stop itself, i.e. its rod and shoe, must be strong and rigid.

- The operator must firmly press the shoe against the support surface while moving the tool.

Features of cutting with angle

Cut at an angle can be performed only by tools that support this function. The cutting process at an angle is provided by adjusting the base of the jigsaw. Manufacturers often equip their products with several clamps - usually at 15, 30, 45 degrees. A square or protractor can also be of great help in controlling the position of the tool's base.

Special attention should be paid to the selection of the file. Homogeneous blades are suitable for the majority of jobs; for non-uniform sawing, it is better to use non-uniform (bimetallic) blades. The cost of such files is somewhat higher than the uniform ones, but they are much stronger and have the ability to bend without breaking.

Cutting with the help of the saw table

The table design allows you to greatly simplify working with a jigsaw, especially when cutting elements of round, oval or complex shape. Such a table can be bought or made by yourself.

The tool is securely fixed from the bottom of the table top, with the blade pointing up.

Switching on and off is done via the buttons located on the side of the table.

In this case, the operator does not move the tool itself, but the workpiece in which the cutting is performed.

This machine allows you to better control the workpiece, to follow the marking line. As with the jigsaw, great effort should be avoided on the object to be processed.

The most frequent breakdowns, how to avoid them and safety measures

It is important not only to know how to cut with an electric jigsaw, but also to try to avoid causes that can lead to breakage of the tool.

Electric motor . Most often in the jigsaw fails the engine. There may be several reasons for failure: burnout of the rotor, stator, wear of the notches on the shaft. To avoid a rotor burnout, you need to purchase an instrument whose power will be sufficient to perform the required tasks. For example, if you need to cut a large thickness of workpieces, a 400 W jigsaw will not be enough - the engine simply will not withstand the load and burn out. This may lead and not enough high voltage. It is not recommended to install reduced speed too often: lack of cooling and high currents can lead to winding burnout.

A notch on the shaft may wear out due to constant shock loads on the tool stem. Impact loads on the stock occur due to improper tooling. Therefore, always follow the recommendations when selecting a saw blade.

Power Button . Sometimes jigsaw owners are faced with a malfunction of the power button. Clicking on the "trigger" leads to the closure of the chain and start the engine. If metal dust gets into the case, the normal operation of the power button may be impaired. To eliminate dust in the process, you can use a special vacuum cleaner (household does not fit). Failure of the "trigger" can cause natural wear of conductive paths. I must say, this process is quite long.

Mechanics . Among the mechanical components, the stock can be a problem: this part is subjected to serious mechanical loads arising during the sawing process. The mechanism for fixing the web is the weakest in this system, since it is directly connected to the stem. Do not be afraid of damage to the gearbox, if the case reliably protects the internal mechanisms of the instrument from dust.

Safety and maintenance of a jigsaw

Basic safety rules must be indicated in the instruction manual. It is strictly forbidden to perform any work while intoxicated. Before starting work, make sure that the instrument is in good condition, there are goggles and gloves, voltage stability in the network. It is necessary to take care in advance of good lighting of the workplace. Power jigsaw should be done in a dry place. There should be no flammable substances near it.

At the end of the work, the instrument is thoroughly cleaned of dust, if possible it is blown with air (with the engine running, the efficiency of blowing will be higher). A lubricant is applied to moving parts as needed. Store the instrument in a dry place. Compliance with these simple recommendations will significantly increase the lifespan of the jigsaw.

Video: Selecting an electric jigsaw and working with it