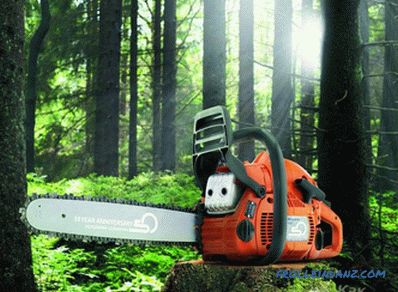

Sooner or later, even the best quality chainsaw will need sharpening. You can sharpen the tool chain yourself. The main thing is to determine in time that it is time to start sharpening.

Circuit status

State

State

Tips Before sharpening a chainsaw, it is necessary to determine the state of the chain. That is how you can find out if it's time to start grinding. The sharp chain differs from the blunt state of the teeth. The teeth of a sharp saw look a little different. If the teeth have the wrong sharpening angle, there are traces of the impact of solid objects like stone, and the edge is not as sharp as before, then it's time to start sharpening.

Tips Before sharpening a chainsaw, it is necessary to determine the state of the chain. That is how you can find out if it's time to start grinding. The sharp chain differs from the blunt state of the teeth. The teeth of a sharp saw look a little different. If the teeth have the wrong sharpening angle, there are traces of the impact of solid objects like stone, and the edge is not as sharp as before, then it's time to start sharpening.

When the chain gets blunt, the chips become uneven, with traces of oil.

The sawing process itself can signal the need for sharpening. Usually, a sharp saw produces clean, large chips, the cutting process is easy, fast and free. Cutting becomes harder and harder.

Sharpening of teeth

Sharpening device

Sharpening device

You can sharpen the chain with a simple file. You can also use a special electric machine, but working with it will require some skills, so a newbie is better to do the process manually. Recently, special sets for sharpening the chain, without removing it from the chainsaw. However, this patented device is intended only for special PowerSharp circuits.

Cover for sharpening the teeth

Cover for sharpening the teeth

For safety, you need to apply a brake before sharpening the chainsaw chain.

When sharpening, the chain is not removed from the saw. File manipulations are done by yourself.

- Having put the chain on the brake, it is necessary to clamp the tool between the knees.

- The work will require a round file with a diameter of about 5-6 mm, as well as a number of files of different shape and size.

- Next you need to install the guide.

- In the process, the cutting teeth are sharpened and the control tooth is removed.

- To remove a control tooth, you need to apply a special pad.

Chainsaw Care

Care

Care

For a chainsaw to last a long time without any problems, you need to properly care for her.

-

Fuel The tool works primarily on a mixture of gasoline and oil. Oil - a very important component, it is necessary for the operation of chainsaws. In no case can not use the unit on gasoline alone. The ratio of gasoline and oil should be approximately 1:40.

Fuel The tool works primarily on a mixture of gasoline and oil. Oil - a very important component, it is necessary for the operation of chainsaws. In no case can not use the unit on gasoline alone. The ratio of gasoline and oil should be approximately 1:40. - When choosing gasoline, you should pay attention to the brands that have an octane number above 90.

- The oil serves to lubricate the chain. It must be regularly added. You must constantly monitor the level of oil in the unit.

- Saw adjustment should be made continuously. In modern devices, this is not a big problem. The oil level can be determined through a special window, and the tension of the chain is adjusted using a special wheel. Moreover, excessive tension is prevented by a special mechanism.

- When working with a chainsaw, safety precautions must be observed. This tool can cause irreparable damage to health in case of careless handling. The most dangerous moment in the work, when the saw bounces in the direction of the operator. A special shield is provided for protection. However, you still need to be extremely attentive. The same applies to sharpening the saw. During sharpening it is necessary to install limiters.

- Before sharpening the chainsaw chain, you need to check the length of the edge of the tooth. If it is too short, it’s time to replace the chain. You can buy a new chain in a specialized store. Installation can be carried out independently.

- Timely sharpening the chain increases its service life - this is an indisputable fact. The earlier the chain enters the grind, the less layer will have to be removed from the edge.

How to disassemble a chainsaw

Before storing the chainsaw, you need to properly disassemble and process:

-

How to disassemble First of all, you need to completely remove the gasoline from the saw. For this little merge it. It is necessary that the tool stalled in the process. Only then can one be sure that nothing is left in the tank.

How to disassemble First of all, you need to completely remove the gasoline from the saw. For this little merge it. It is necessary that the tool stalled in the process. Only then can one be sure that nothing is left in the tank. - The oil contained in the tool must also be poured. It is not useful for any other needs, because it contains steel filings.

- When done with liquids, you should start disassembling the tool. All parts must be thoroughly cleaned. The air filter must also be cleaned.

- After removing the chain, clean it and put it in a container with engine oil. It will be great if it remains in it for the entire shelf life. Thus, the chain will remain best.

- Most often, of course, after cleaning, the saw is collected (together with the chain) and sent to a dry warm room. Keep the tool in the cold can not.

If you leave the chainsaw in the cold, and then start driving sharply, then there is a possibility of serious damage to the saw headset.

A chain, like any metal, is compressed in the cold. With a sharp start, it will simply break or damage other elements of the tool. It threatens costly repairs. After all, the saw itself is not the cheapest unit. In some cases, you will have to re-purchase the headset. Therefore, it is better to follow the instructions for use and storage tools. This will save on unnecessary expenses. The chain can serve very long with careful care.

Video

Manual sharpening technology is presented in the following video:

The automatic system for sharpening the chain is described further: