How to lay tiles on wooden floor? This is a question that excites many, since it is rather difficult to combine incompatible materials. This is due to the property of wood to expand and narrow depending on the temperature. Such movement can damage ceramic tiles. Most often chips are formed on the tile, the seams crumble and individual elements can peel off. In order to lay ceramic tile on the wooden floor, it is necessary to study the principles of work.

The wooden floor on which the tile is laid must be waterproof.

The following tools will be needed for laying:

- spatula;

- rule;

- rubber hammer;

- level ;

- tape measure;

- tile cutter;

- lacing.

Why it is not recommended to lay ceramic tiles on a wooden floor?

To put tile on a wooden floor is an extremely unwise decision. This is due to several key points:

Laying options.

- Wood, unlike ceramic tiles, is warm. Therefore, to cover it with cold tiles is impractical.

- The laid tile hermetically closes the wooden base and prevents air penetration. This contributes to processes such as decay, which will subsequently destroy the wooden floor.

- A tile has a significantly longer shelf life than wood.

- A non-static base of wood can cause the destruction of a tile.

It is very important to know that it is strictly forbidden to lay ceramic tiles in a new wooden house. The first few years the design shrinks, and this will necessarily lead to an increase in flooring. The minimum period of shrinkage that must be waited in order to use ceramic tiles is 2-3 years.

Assessment of the condition of the wooden floor: features

Before proceeding with the laying of ceramic tiles, it is worthwhile to thoroughly approach the preparatory process. First you need to assess the condition of the wooden floor. There can be three types of condition:

- after dismantling the floor is unsuitable, only the lag construction remains;

- logs covered with plywood, chipboard or OSB;

- fit condition.

It is very important to inspect the coating: it must be intact, with no visible signs of rotting or mold. The quality of the repair depends on the general condition of the wooden floor. In order to ultimately lay tile, it is necessary to make a static, smooth and durable surface.

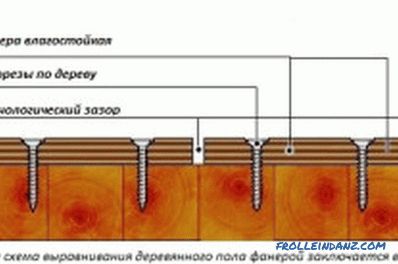

The first way to prepare the base is dry leveling

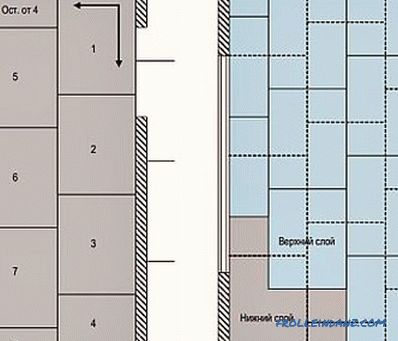

Scheme of dry floor leveling.

Today the most reasonable and common method of leveling the floor and making it static is the dry leveling method. In order to lay the tile, you must apply moisture-resistant plywood. It is thanks to her that the surface will be solid and immovable. In order to perform such a floor, you can use several methods:

- Today there are ready-made kits that significantly speed up the process of installing or repairing the lag. Such kits include plastic screw supports, which are used to regulate the surface.

- The construction of a new lag system on top of the old plank floor and the subsequent covering with sheet material. The main disadvantage of this floor is the reduction in useful height.

- The old floor can be covered with an additional layer of sheet material.

Sheet materials are also subject to linear movements, but the indicators of such movement are insignificant. In order to protect the tile from destruction, it is necessary to use a two-component polyurethane adhesive, which differs from the usual higher elasticity.

Before proceeding with tile laying, the joints between the sheet material must be carefully ground and filled with sealant.

In addition, in order to increase moisture resistance, the entire floor area must be covered with a special primer composition.

In this method of preparing the base, you can highlight some advantages:

Tools for laying tiles.

- The void between the lags can be filled with insulating materials, which will significantly increase the heat and sound insulation of the room. As such material, expanded clay, mineral wool, foam plastic can be used.

- Carrying out all installation or repair work takes little time.

There are some drawbacks, the main one being the height of such a floor. To hide the difference, it is necessary to make a small threshold at the door. By increasing the height of the floor, the height of the room will be slightly less.

The second option for preparing the base is the wet-screed method

It is almost impossible to make a complete concrete screed on the wooden floor. This is due to the carrying capacity of the wooden structure. Therefore, the alignment of the wooden floor is carried out in a lightweight form. In order to make such a screed properly, you should follow the principles of creating a floating floor. The essence of this method lies in the fact that the concrete layer should not come into contact with the walls and the underlying wooden base. To do this, before pouring the mortar onto the wooden base, a waterproofing film is made.

Along the perimeter of the entire room between the wall and the screed should also remain a gap. Such moments will allow the wooden base to narrow and expand freely. In this case, the concrete layer and ceramic tiles will be in a static position.

On average, the thickness of the screed that is poured onto the wooden floor should not exceed 3 cm. It is not recommended to do more, as the load will increase. Less thickness will not be reliable enough for laying tiles.

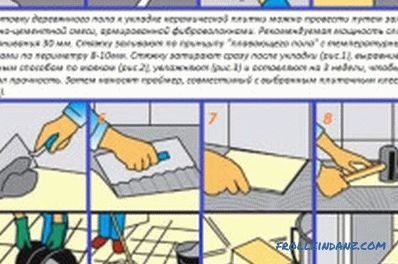

Stages of the work

Tile laying sequence.

To level the floor with a screed, you must first check the quality of the coating. Wood is subject to such processes as rotting and the formation of fungi and mold, so it is recommended to inspect the entire floor, dismantling the upper flooring. If there are damaged items, they must be replaced with new ones. Before assembling the structure, all parts must be soaked in antiseptic agents.

It is worth paying attention to the distance between the lags: if the pitch exceeds 50 cm, then it is worth strengthening the construction with additional elements. This is necessary in order for the wooden flooring to withstand the load of the concrete solution.

As a board flooring, you can use boards 4 cm thick, pre-treated with an antiseptic. In order to maintain ventilation between the boards, it is necessary to leave a gap of 1 cm. Sheet material with a thickness of at least 12 mm is placed on top of the plank floor. To fasten the sheets, it is necessary to use galvanized screws, the step between which should be no more than 20 cm. Be sure to leave 3 mm gaps between the sheets.

Paraffin or bitumen paper is recommended as a waterproofing layer. You can also use dense polyethylene. All materials are overlapping. Along the perimeter of the walls, it is necessary to create an overlap of about 10 cm. In order for the material not to interfere with the work, it can be attached to the wall with adhesive tape.

The screed solution can be prepared by yourself or you can purchase the ready mix at the hardware store. For alignment, you must use a rule. After the screed is completely dry, you can begin to lay the floor ceramic tiles. It all depends on your skills and abilities. You have already done the main job. Good luck!

Didn't find the answer in the article? More information on the topic:

-

Nuances of leveling the chipboard

Leveling the floor chipboard plates accompanied by a number of activities. Preparatory work, installing lathing, mounting chipboard. Practical recommendations.

-

How to make yourself a log house for a well

Instructions: how to make a log house for the well. The stages of the installation of the well do it yourself. What is required for work. The advantages of wooden logs over wells or concrete rings.