During the construction of modern country buildings, their future owners often have to independently engage in the manufacture of floor decks. However, before you do the overlap between floors, we strongly recommend everyone to get acquainted with the technology of their facilities.

Ceiling requirements

Floor construction

Floor construction

Interfloor subject matter overlap, the choice of which must take into account the strength and durability of the prepared structure. At the same time, as additional requirements for structures of this class, the following characteristics are usually considered:

- thermal insulation properties of floors;

- sound insulation between floors;

- fire resistance .

However, the main condition for the effectiveness of interfloor overlappings remains high structural strength, providing the ability to finish ceilings and reduce the likelihood of cracks and other defects on them.

When assessing the advantages of interfloor structures, special attention is paid, of course, to their sound insulation characteristics. If there are rooms with a high level of humidity in the project (a bathroom, for example), an additional advantage may be the presence of waterproofing in them.

According to the method of their installation, all structures of this class can be divided into beam ceilings and monolithic type floors.

Beam overlaps of type

Floor plan with wooden beams

Floor plan with wooden beams

Beam structures are made on the basis of metal, wooden or reinforced concrete beams with their subsequent finishing with all necessary elements of floors. Consider each of these categories in more detail.

Wooden beams

Overlapping structures made on the basis of wooden beams are the most common type of flooring in private construction. Such popularity is due to the following reasons:

- ease of floors made of "business" wood;

- simplicity and ease of installation of beams;

- able to do without using a special equipment (lift or crane).

The strength of the constructed structure is largely determined by the width of the span of the wooden floor. Since the tree is easily deformed, to ensure the design bearing capacity of the beam should be laid with a normalized step (from 0.7 to 1 meter). In this case, the following rule must be adhered to: the longer the gap between the beams, the thicker they must be.

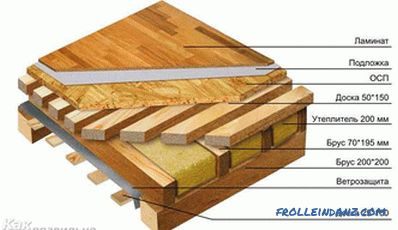

Selection of a section of wooden beams is made taking into account the optimal ratio of their sides (usually - 7: 5). In the intervals between them is sound and heat insulation material, laid directly on the so-called "hemming", which is also the ceiling for the lower room. In addition, to protect the structural elements from fire, as well as in order to extend their service life should be processed with appropriate protective compounds.

Construction of interfloor overlap

Construction of interfloor overlap

Beam sections that are in contact with bricks, in particular, should smear with resin and wrap a piece of roofing material.

The laying should have special niches in which the beams are fixed with anchor bolts of a suitable size. All subsequent operations are performed in the following order:

- directly on the "hemming" fit a layer of insulation consisting of mineral wool or other lightweight insulation material;

- then a layer of waterproofing is laid, which function to carry out a usual polyethylene film;

- a roll forward is made over the beams, consisting of a draft and finishing floor, which is usually covered with plywood on top.

Metal beams

Due to their durability, metal beams have smaller dimensions and save on the total amount of floor space required. At the same time, the bearing capacity of structures is markedly increased, surpassing that for wooden beams many times over. But before you make the overlap between the floors of metal, you should know that the latter are not without certain disadvantages, the main of which are low corrosion protection and the inability to provide the necessary level of sound insulation.

Monolithic floors

Reinforced concrete

Reinforced concrete

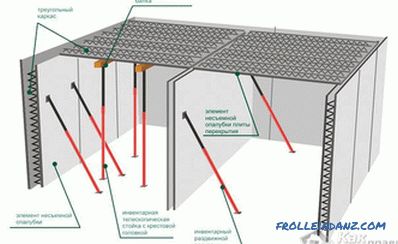

Solid or flat girders are usually made of materials of homogeneous structure in the form of slabs or prefabricated (precast-monolithic) panels. Classical reinforced concrete slabs placed on top of the bearing walls and partitions of buildings can be attributed to the products of this class.

Scheme of precast-monolithic overlapping

Scheme of precast-monolithic overlapping

lifting equipment.

Video

To calculate the number of beams, special programs are used, how to use them, see below:

We also offer you to watch a video about making a monolithic concrete floor: 2>