Floating floor is quite simple and accessible for every method of flooring. This technology allows you to lay the flooring without the use of glue. That is, the draft layer and the finishing layer do not have a rigid connection. The whole point is to fix the floor with baseboards, as well as longitudinal and end edges. This article will describe the device of the floor of the laminated board.

Preparation of the concrete foundation

Lining the tape around the perimeter of the floor

Lining the tape around the perimeter of the floor

if construction occurs at the initial stage, then it is necessary to prepare a concrete base, for which a crushed stone of the same thickness is poured onto a pad of compacted sand with a layer of 25-30 cm. They level and also tamp, after which a sand-cement screed of 8-10 cm is made from above. The proportion of mortar for the reinforcing screed is 3: 1, where there are three parts of sand and one part of M-400 cement.

Consider in detail the implementation of the tie. Reinforcing bars, sometimes steel rods, are placed on the base. Then install the lighthouse elements (trimming water pipes, wooden slats), at a distance of 1.5-2 meters from each other. Their height should correspond to the top surface of the fill. Where required, wedges or plywood are placed under the lighthouses. And so that the slats do not move, they are fixed with a plaster composition. After that, the level of the horizontal surface is verified.

After completing the work, it is recommended that the beacons be removed, and the resulting depressions be sealed with the same composition.

If more stringent requirements are applied to the surface, a self-leveling compound is applied on top. For example, "Thom sit DX" or "Atlas SAM 200".

Powder (primer) is poured into a suitable container and filled with water according to the attached instructions. Everything is thoroughly mixed (it is better to use a perforator with a serpentine nozzle). It should be a homogeneous mass. After 4-5 minutes, the operation is repeated.

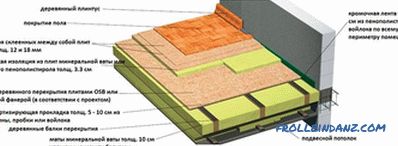

How does the floating floor

How does the floating floor

work? The resulting solution (liquid sour cream consistency) is poured onto the floor, starting from walls of the opposite door. At the final stage, the plane is rolled with a needle roller (to remove bubbles). Allow to harden the solution (day or two) and produce a primer. Next will be described in detail how to make a floating floor.

Flooring of laminated parquet

Laying of the floating floor

Laying of the floating floor

Now moving on to the finishing finish . Let's sort the option of laying laminate. We will need:

- laminated board;

- thin foam;

- waterproof glue;

- distance pads;

- adhesive tape , felt clamp and pencil with a ruler. Useful and mount.

The material is unpacked and allowed to lie down (day, two) during this time it will take the required size. The substrate must be dry and clean. Then foam is spread for soundproofing purposes (no need to glue it). You can use any suitable insulating material (as long as it is soft).

Laying Rules

Laying Rules

Installation begins at the far corner of the room and from its long side. A gap of 6-8 mm is left between the first panel and the wall, for which remote spacers are installed. Board draw a crest to the wall.

Now they glue the groove with a dotted line and insert the crest of the second panel into it. Thus, 3-4 parts are laid. The end seams in the adjacent rows are placed with an offset of 30-40 cm. The length of the parts of one row is clamped with a clamp, missed by their glue. Do not forget to put felt under the clamp claws, and glue the end edges with glue. After 3-4 passes, the rows are compacted with a wooden hammer. It will be correct when the distance clearance around the perimeter of the flooring is 7-8 mm (thickness of gaskets).

If the last panel is laid along an uneven wall, its contour is marked on the part. Saw jigsaw and only then dock. At the final stage, all side gaps are closed with baseboards.

Video

See below the instructions for laying a floating floor: