I didn’t take the tools in my hands for a long time, and my hands were longing for work ... Well, it means it's time to make something new. Join me and you, dear readers. This time I will tell you how to make a bed with your own hands.

Before you start making anything, I always “sham” on the Internet in search of what I want, but more often I cannot find anything suitable. Maybe I'm just too picky? Something I am borrowing on one site, something "stealing" on another, and so on until my plan is mature, which is, in fact, a hybrid of various network projects. Every great designer is actually a big thief!

Before you start reading my story-instructions on how to make a bed, I want you to measure your mattress and make sure its size is close to 200 * 150 cm. Why is this important? If you can not find the answer to this question yourself, I will tell you: the mattress should "fit" into the bed frame! If the size of your mattress is slightly different from the size of a queen, do not forget to make the necessary adjustments when cutting lumber. In addition, pre-determine the purpose of the bed - whether it is a standard bed for sleeping or a couch for a day rest. It depends on how to make a decorative finish.

Materials and tools you need to create a bed

Materials

Now go to the nearest building materials store (with a tape measure) and purchase the following sawn timber:

- 4 boards 2. 5 * 20 * 240 cm (pine) for making a frame;

- 3 boards 5 * 10m240 cm (pine) for making support beams;

- 3 boards 2. 5 * 5 * 240 (pine) for decorative finishing;

- 1 bar of 10 * 10 * 240 cm (fir or pine) for the manufacture of legs;

- 19 boards 2. 5 * 7. 5 * 240 cm (pine) for the manufacture of rack bottom.

If you walk through the big stores selling building materials, you will notice that there is wood of various quality available for sale. Choose straight boards with a minimum number of knots (the more knots, the more time and effort you will have to spend on polishing). Of course, high-quality lumber is more expensive, and in this case you have to look for the very "golden mean". For example, I purchased high-quality materials for the manufacture of the frame and decorative trim, I took second-rate wood for the legs, but I bought the cheapest grating slats I could find.

Tools

Required tools: (Do not be alarmed to see this list! Your investment will pay off very soon, and then save thousands and thousands ...):

- tape measure;

- circular saw;

- Kreg Jig set (device for drilling holes at an angle);

- drill ;

- glue for wood;

- adjustable measuring angle;

- belt grinder;

- clamps;

- 30 mm self-tapping screws;

- 50 mm self-tapping screws;

- 60 mm self-tapping screws;

- water-based acrylic varnish;

- stain;

- brushes;

- emery paper

- coating on wood.

Lumber cutting

Frame:

- 2 boards 2. 5 * 20 * 205 cm

- 2 boards 2. 5 * 20 * 148. 5 cm

Supports:

- 3 boards 5 * 10 * 202 cm

Legs:

- 6 bars 10 * 10 * 10. 5 cm

Slatted bottom:

- 19 boards 2. 5 * 7. 5 * 148 cm

Decorative finishes:

Standard bed.

- 2 boards 2. 5 * 5 * 157. 5 cm

- 1 board - 2. 5 * 5 * 202 cm

Couch (what I will do).

- 2 boards 2. 5 * 5 * 150 cm

- 1 board 2. 5 * 5 * 209. 5 cm

Making the frame of the bed

To begin work on creating your own wooden beds from the manufacture of the frame.

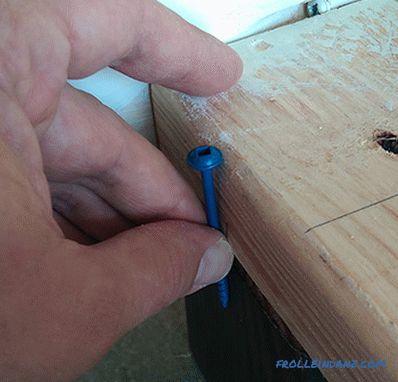

I fastened its boards, twisting the screws from the inside at an angle. And for drilling at an angle of the guide holes, Kreg Jig turned out to be indispensable. The tool is very convenient and easy to operate. Try it, you will not regret it!

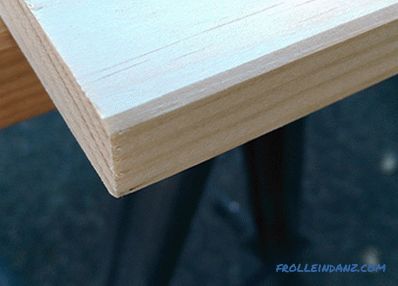

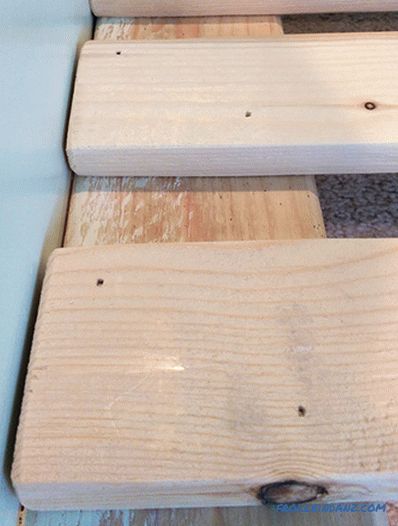

To give the edges of the detail a neat look, I processed them using a manual strug. If you do not have such a mini planer, you can use a grinding machine for these purposes.

Looks great.

I processed the ends using a grinding machine.

After all the parts were polished, and the guide holes were drilled in their ends, I applied a little wood glue to the joints and. ..

... fastened the boards with 30 mm self-tapping screws.

Wipe off any excess glue with a damp cloth until it is dry.

Through the square I made sure that all the corners of the assembled structure are straight.

The frame is ready.

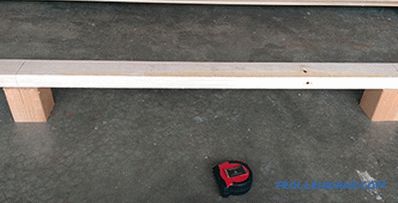

My advice: at all stages of work, take careful measurements to make sure that you are doing everything correctly.

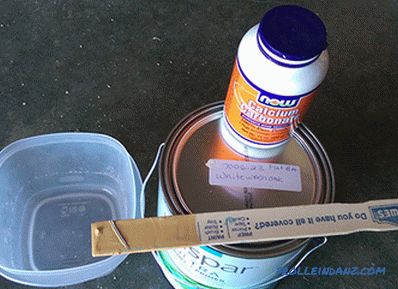

Now is the best time to paint the frame.

Why not make a paint based on calcium carbonate powder at home? I borrowed the recipe on this site: hnydt. co / 2013/08/06 / diy-chalk-paint /. For its preparation, I used the paint brand Valspar color bleached oak.

It does not look exactly like I expected ... Well, all right.

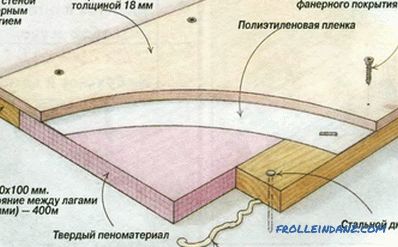

Making the supports for the rack bottom

Instead of watching the paint dry, I drilled the guide holes in 5 * 10 cm boards that will serve as supports for rack bottom. To do this, I again used Kreg Jig, reconfiguring it to a large thickness of the board (simple adjustment using an Allen key).

To determine the location of the guide holes, measure 5 cm from the end of the bar, and then mark every 25 cm.

As a result, you should have the same effect as in my photo.

When the paint was dry, I set the frame on its side to attach the prepared bars.

Using an adjustable square, I drew a line 5 cm from the bottom of the frame.

He generously applied joiner's glue along the entire length of the bar and along its ends.

I placed the bar on the place intended for it and fastened it with 50 mm screws at the ends and in the center. Then I turned the frame over and pressed the bar along its entire length with clamps. There should be no gaps between the bar and the frame! Now you can screw the screws into all other pre-drilled holes.

Marked the center of the sides with a length of 148. 5 cm (i.e. 74. 25 cm from the edge).

Here you see a 5 * 10 cm bar from which a central support beam will be made. I make two guide holes at one end and one hole at the other end.

I laid a support under the bar so that it would be on the same level as the line drawn 5 cm from the floor (and with two other supports). Applied glue and screwed screws.

Then I filled all the holes with wood putty . After it dries, you need to polish these places with fine-grained sandpaper.

Making the legs of the bed

For the legs you need a bar with a section of 10 * 10 cm and a length of 10. 5 cm. We need to prepare six such bars.

Measured 2. 8 cm, set the saw 45 ° and combined its blade with the mark made ...

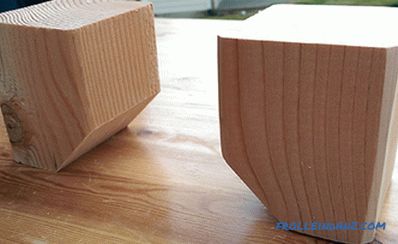

These are the legs I got. In my opinion, they look good. On the left - just sawn, on the right - already polished. Basically, you can skip this stage completely. It's your choice, after all!

This is how the beveled legs look under the frame.

Under 5 * 10 cm with supports of 10 * 10 cm, the legs sit perfectly.

Two legs, located under the central support, I did not begin to mow.

To determine the location of the central legs, I measured 50 cm from each end of the support beam (1/4 of its full length). Drew the center lines and the perimeter of the legs. Having done this, I can not worry that the drilled hole will be outside the leg.

Creating decorative elements of the bed

We now turn to decorative decoration. Since my bed will perform the function of the couch (it will stand a long side against the wall), the longer piece of the decoration will be frontal. If you are making a standard bed, see the dimensions given at the beginning of the article.

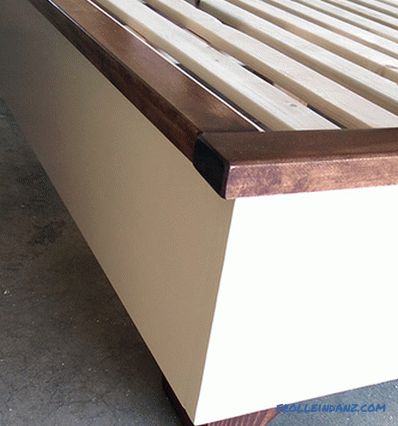

I have polished the slats for the trim and the legs. .. looks beautiful!

Now that all the parts are polished, you can start painting them! For this, I used a dark walnut stain.

After the stain had dried, I covered the wooden surfaces with Minwax water-based varnish.

After the first coat of varnish has dried, the surface must be sanded to get rid of any bubbles and discontinuities. Use a sanding pad (or a piece of wooden block) with fine-grained sandpaper to do this. Pay attention to the white film on the tree - it is perfectly normal!

It remains to wipe the dust from the sanded surface and apply the second and third layers of varnish.

Making slats for the bottom of the bed

Now the decorative slats can be set aside for a while and start cutting the slats for the bottom of the bed.In order not to spend a lot of time on measurements, I cut out the first rail and used it as a reference. Simply align the ends of the rails and draw the line.

The finished battens should be sanded and the wood dust removed with a damp cloth.

Fastening the legs and decorative elements

I used 60 mm self-tapping screws (two on each leg) for attaching the legs. Before screwing them in, I drilled the guide holes of 2. 5 mm with a drill. Pre-drilling holes reduces the risk of splitting wood. In addition, the guide holes greatly facilitate the process of screwing screws.

The same applies to the central legs.

It's time to decorate. Apply glue to the upper part of the frame (the most effective application is wavy!) And on the ends of the decorative strips.

Press the trim strips to the frame with clamps. I used unnecessary trim boards as pads. This allows not only to increase the pressing area, but also to reduce the risk that traces of clamps will remain on the decorative slats.

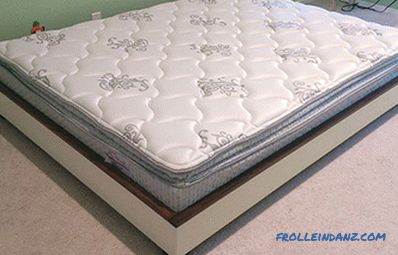

Here we are close to completing the manufacture of the bed with your own hands, its outlines are clearly visible. It remains to secure the bottom rails. I used a pneumatic hammer and 30 mm nails. You have options! You can use parquet nails and hammer them by hand. You can screw in the screws by pre-drilling the holes. You could probably even glue the slats to the supports.

I drove two nails at each end of the rail and two nails into the middle support.

Pay attention to the location of the screws, securing the legs. Do not fall into them!

In order to distribute the slats evenly, you can use an insert from unnecessary cutting of the board. I did not do this, but, nevertheless, all the slats were located at the same distance from each other.

Fixing the last fragments of decorative decoration ... In my opinion, it turned out well! What do you think?

The mattress fits perfectly!

And here are the blankets with pillows. ..

Well, well, friends. Now you also know how to make a bed of wood with your own hands. So, a visit to the furniture store is canceled!

Source: hnydt. co