Lags - this is a timber that can be made of wood or various polymers. Their installation on the basis of the floor can perform its finishing coating.

Lags are wooden bars of various designs and shapes that are used to make the floor.

Lags have a different design and, depending on it, can vary in shape and size. Depending on these features, there are different ways to help solve the problem of how to fix lags.

Types of lag and flooring

Despite all the variety of designs, lags have the same function and perform the following functions:

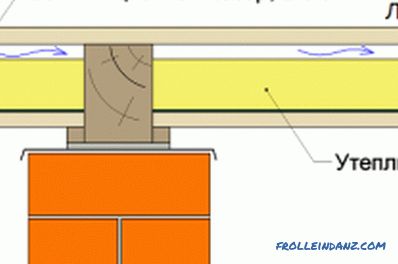

When installing lags, there is a ventilation gap that allows you to ventilate the space under the floor.

- Create a space under the floor that will be ventilated.

- Helps to make a horizontally flat surface.

- Reduce noise.

- Increase thermal insulation.

- They distribute the load on the lower layers of the base of the floor.

Arranging the floor with lags can be done in the following ways:

- On an earth foundation.

- On the ceiling of buildings.

- On a concrete base.

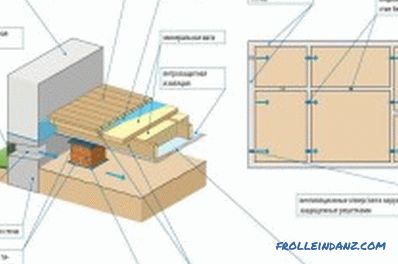

To equip the floor on an earthen base, it is necessary to remove the upper vegetative layers of the soil. After that, you need to tamp the prepared surface and pour gravel on top of it. The gravel layer should be 40-50 mm. A concrete mortar is poured on top of the gravel, waterproofing is arranged, and then a sand-cement screed is made. On the resulting structure you need to put and fix the logs, on the surface of which you need to mount the final coating.

Floor plan on lags on the ground.

You can use another installation method. For its implementation it is necessary to make columns of silicate brick. Their height should be 20-30 cm. They are built only on a concrete foundation, the depth of which should not be less than 50-60 cm.

Bricks on the top row should be mounted in a perpendicular position relative to the log. To maintain the necessary levels of horizontal arrangement, you can use special linings between the pillars and the lags.

The required number of brick columns will be determined relative to the material of manufacture and the design of floor bars. In order to reduce this number, it is necessary to use large-thickness bars, and on top of them install a second layer of thinner material.

The thinner the stacked material is, the smaller the distance between the pillars should be. Determination of the optimal number of pillars and lag thickness should be carried out at the design stage.

Setting the lag on the floors

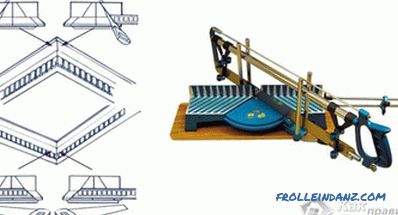

In order for the floor to be even, logs must be loosened with a plane.

Beams for overlapping are often not planed until an ideal surface is obtained, this does not allow for a flat horizontal floor. Therefore, in order to avoid possible curvature of the floor, which can later lead to its creaking, you need to adjust them yourself using a planer. In those places where there will be large level drops, you can use linings.

To perform all installation work, you need the following tool:

- Electric Planer.

- Drill or screwdriver.

- Construction Level.

- Hammer.

- Screwdriver set.

After laying the wooden boards, it is necessary to mount them. You can perform it with dowel-nails. For ease of installation, you need to drill holes in the logs, the diameter of which should be less than the diameter of the dowel-nails by 1-2 mm Moreover, the preparation of the pre-holes will help avoid the cracking of the wood. For fixing the lag is used 2 holes on the ends.

If large gaps arise between the beams, then the second layer should be laid on top of them. These logs should be installed sideways (with a smaller thickness). You can use thick plywood, which must be laid in a staggered manner.

Fastening on concrete

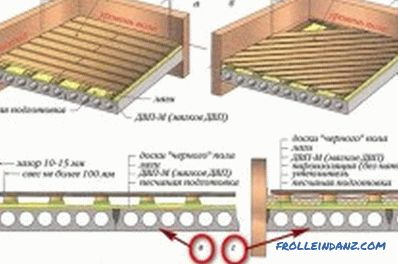

Construction of wooden floor along the logs.

In order to install the lags on the concrete floor, the procedure for their installation will be slightly different:

- Laying the waterproofing material.

- Installation of a heat-insulating and noise-insulating layer.

- Pouring a cement-sand screed.

- Installation of raised floor and log.

- Installation of the final coating.

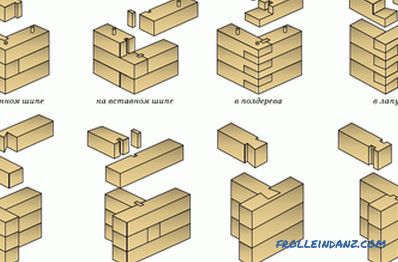

When laying a lag on a concrete base, their length may be different, but be at least 2 m. If the length of the room is longer, you can dock on the ends of the material. To enhance the strength of the docking joints, it is possible to make longitudinal sections at the ends of the beams, which are 10–15 cm long, and their width is equal to half the width of the beam.In the two adjacent rows of butt joints there should not be a single joint longitudinal gap, they should be spread by 40-50 cm.

The base for the beams should be carefully prepared. For this purpose, all the required layers are laid (waterproofing, noise insulation, etc.). To achieve structural strength, all insulating and insulating layers must be poured over with a cement screed.

In order for the resulting structure to be well connected (fixed), it is necessary to fix the beams to the base with anchor bolts. When gaps between the rows are formed, they must be sealed with the help of heat-insulating materials. This should be done very tightly, not sparing insulation.

Recently, adjustable lags have become widespread. In their body there are plastic sleeves in which the thread has already been prepared. Racks from plastic twist into these holes. These racks are attached to the base of the floor using dowels-nails. The presence of such racks allows for a small offset of the lag in height, which will help to accurately set the horizontal level of the floor covering.

If you approach the solution of the problem correctly, how to fix the logs correctly, this will help to achieve a perfectly flat surface of the floor covering. It will make living in the house comfortable and comfortable.

Didn't find the answer in the article? More information on the topic:

-

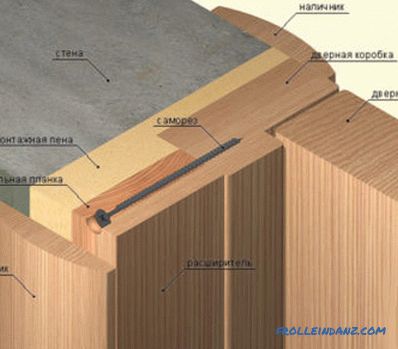

Wooden doors for your own homework

Recommendations for how to make wooden doors with their own hands. Options for interior doors. What materials can be used for this product. Installation of the canvas.