The essence of the caulking process is to seal the joints and joints. To make living in your own home comfortable, you cannot do without such a construction phase. What and how to caulk a log house is a matter that requires a detailed investigation, since neglecting them will affect the construction of the house as a whole.

The insulation by a caulk of a wooden house is done by plugging the gaps between the logs outside and inside the house.

The types of materials for the caulk vary: moss, jute, tow, batting. For each building there is a type, for example, it is customary to caulk a rounded log with a rope that looks like a decorative element. All materials purchased in stores must have quality certificates.

Materials used: features

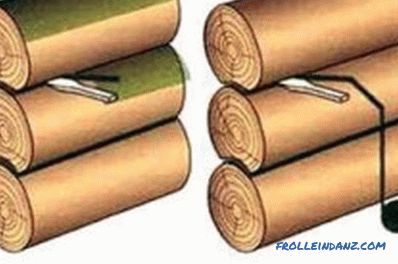

Methods of caulking iron.

- Moss. Known for a long time the material used for caulking. But now the masters do not recommend using it for such a purpose. Why? Over time, the moss turns into dust, and the wind simply inflates it from the cracks. Accordingly, there is no insulation. It is very good to use moss for a bath both as a joint seal and for laying a timber or log. Considering that this natural material never absorbs water, it is better not to find it, but only as a warming bath.

- Tow. Also not very recommended material for caulking iron. It is very difficult to twist it so that it does not crumble. And it will be necessary to tighten tightly, for the birds have long chosen such fiber for their own construction. It absorbs vapors and condensate, so the tow is always wet, and in the heat it crumbles into dust, and caulking must be done again and again.

- Jute. The material of the new generation. Not to be confused with jute felt. Such a compactor is not hygroscopic, therefore, if you caulk a log cabin with jute, it will remain dry. And felt will absorb all the moisture, besides, the mole loves it very much. We must be attentive to the recommendations of sales assistants.

- Lnovatinovaya tape. Modern material with all the qualities of jute: does not interact with moisture, easy to install. But he is much rougher that will take more time to work.

- Caulking with a sealant is a new method of sealing and quite effective. Only necessarily bottles with a mass must be appropriately labeled.

The list is incomplete. Each owner can use any compactor in the process, but being guided by the conviction that grandfathers have built this way, the caulker cannot be made good - they (grandfathers) had no choice and made what to.

Tools for caulking

To do the job qualitatively, you need the appropriate tool:

- caulk is a straight-type caulking iron; >

- kiyanka;

- additional tool for forming the roller;

- mittens or construction gloves.

How to caulk a log cabin correctly?

Tools for a caulker.

Preparation includes all manipulations with the frame: removal of old material, cleansing of logs or lumber from excess chips and litter. For such work, the center caulker is ideally suited, with its rounded blade, it will easily get all the excess out of the seams. Can be vacuumed. It will also be a good idea to walk around the seams with chemical protection from fungus and mold and thoroughly dry them. An exception can be made only for caulking moss - it will still have to soak.

Then we proceed to the process itself. There are two technologies for laying the compactor: in the set and in the extension. The first one is convenient for coil caulks. Fibers are twisted into a similarity of a ball and the thread formed is pushed into the gaps by forming loops and a straight caulk. Kayanka hit the handle. This should be done carefully so that the blade of the tool does not damage the material. The second method can be applied to caulk a log cabin with jute. The material is spread out over the entire length of the log, and one edge is pushed into the slot, then the second is rolled up in the form of a roller and finished with a double-horned tool, all the material is caulked into the seam. It is impossible to hurry, otherwise the caulker will go in waves, and it will have to be cut, thereby leaving room for gaps. That's all.

Before the start of finishing works, it is necessary to cut all the cracks in the log house and treat it with an antiseptic.

The essence of the above is clear. But in order to make a cauldron correctly, whether jute or moss is unimportant, one should know:

- The process consists of three stages: the first caulker, the second and the last. The first is supposed to be done immediately after construction. Do not be too zealous to get down to business. The material is placed for testing, so that during the initial shrinkage, construction flaws are visible. The second caulking iron of a log house occurs in a year, and the last cavern after a few years, when it becomes clear that the log house had "sat down" finally.

- Lead cant be carried out neither in cold nor hot weather. From 10 to 20 º C heat will be just right.

- The log of the log begins from the bottom up and fully along the crown, that is, round. It is not necessary to do everything at once, otherwise there is a risk that the layer of material laid in the seam will be uneven.

- It is impossible to disregard round elements and corners, a semicircular instrument was invented for caulking them.

Blade with different materials

Types of materials for a log caulk.

The compaction of the frame with moss occurs as follows: the litter is cleared out of the seams, and then the pieces of natural material, which are preliminarily wetted, are placed in the slots. Moss is necessarily moistened, otherwise it will be difficult to lay in the seam. But the caulking log of lumpy jute or ribbon is stretching (the method described above).

It is customary to seal the seams on the rounded constructions, because their appearance needs a decorative caulker. It can be beautifully performed by a professional, but it’s also worth a try. Pistol mass is squeezed into the seam and a spatula installed exactly between the logs, the excess is removed.

Sealant is used, if the structure of the log house is not intended for plating, beautiful seams are visible from afar.

The caulking unit of the log house is set: a ball is twisted, and the material is compacted into gaps and grooves by twisting the loops. Sviv need to carefully and push deeply so that the birds did not get.

The methods for separating the frame with moss or other materials are different from each other, but nevertheless, the essence is the same - sealing of interwoven seams and gaps. The venerable carpenters even have such a trick - to level the entire log house with the help of a caulk, putting a layer of more or less where necessary. Amateurs do not need to do that - there is a risk of knocking over a log or a bar.

From a job such as a log cutter, you cannot go anywhere. Even if the houses are made by high technology, wooden construction involves such an installation. For a comfortable stay depends on many factors, and even more so on a robe.

Didn't find the answer in the article? More information on the topic:

-

Processing of wooden floors

Processing of wooden floors: how to save the flooring. Varnish, wax, oil, advantages and disadvantages of materials. All the secrets of wood flooring tools.

-

How to make a cauldron of a wooden house?

Cauldron of a wooden house: features of the choice of material for carrying caulks, technology caulking of wooden houses. Tools and materials used in the work.