We build from a bar. It is an incredibly comfortable building material. With it, in a short time you can build a house, bath, cottage, gazebo and other buildings. If we compare it with a conventional log, then the cost of such raw materials will differ significantly upwards. High quality timber is a very durable material. It is characterized by low weight, economy, visual appeal, no need for additional finishing.

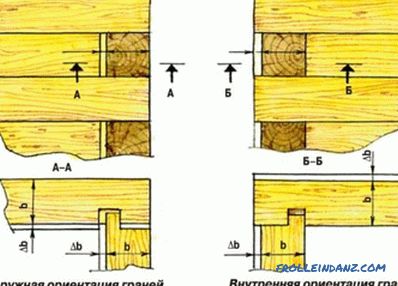

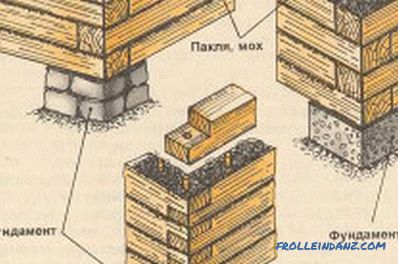

Beam orientation schemes.

The main advantage of a bar is its exact dimensions. If we compare the technology of building houses from logs, the laboriousness of this process is immediately apparent. Here you need to show not only diligence, but also professional skill. A timber, on the contrary, is constructed easily; it has a smooth and even base. Laying any insulating material between its crowns, you can easily build any building from a bar.

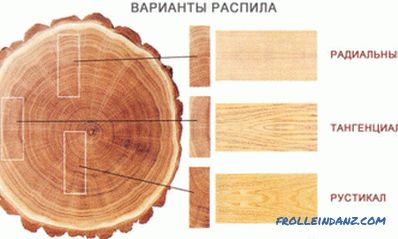

However, despite the ease of installation, a timber is inherently a tree, which is very variable, and these figures depend on the type of tree, the presence of the cut, the number of knots. At any time he can lead.

Drying of timber has a significant effect on the geometry of the material. In the construction of wooden buildings is not taken material of natural moisture. The use of dry raw materials makes it possible to save money on the exterior wall cladding. To determine the quality of the material, you should look at the connection of the grooves and ridges, they are required to perfectly fit into each other, there should not be gaps and gaps.

Some features of the timber

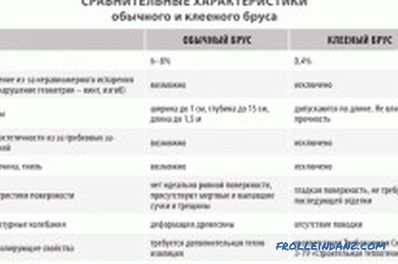

Comparative table of the characteristics of the laminated timber and the usual.

The main advantages of such materials are:

- The natural base is environmentally friendly.

- Attractive external indicators.

- Wood has a low thermal conductivity.

- Woods give a pleasant microclimate to the atmosphere at home.

- Any building can be built very quickly literally in a season.

- Beam structures are practically not amenable to natural shrinkage. For this reason, it is not necessary to wait more than one year before it ends.

- For the construction of such buildings do not need special knowledge and skills.

Defects of the beam:

- Ability to spread fire. To prevent such troubles, often used mixtures, flame retardants, they are saturated with a bar just before the installation work. It will not be possible to achieve absolute refractoriness, but you can save the building from fire.

- Ability to rot and mold on the surface. In this case, antiseptics help eliminate such manifestations. Such measures will help preserve the base of the tree from the imminent destruction.

- Any external weather changes affect the condition of the wood. Such phenomena can be prevented by treating the walls with varnish or paint, by building a reliable water flow and drainage system. A well-established roof can protect the structure from unpleasant consequences.

- The foundation erected in violation of technology is the reason for the destruction of the timber. Preparing to build a foundation, you should take into account the nature of the soil, this circumstance should be included when drawing up the scheme. So, freezing can lead to a change in the configuration of the structure and subsequent dismantling.

Tools for working with a bar.

There is practically no person who would not dream of living in his own house, built of pure material from an environmental point of view. Increased attention in this regard is paid to buildings made of natural wood. On the question of how to build from a bar, many homeowners are embarking on an answer, embarking on the construction of such structures. To answer this question, you can refer to the material below.

Virtually any business always starts with planning. Here it is necessary to select in advance the model you like, schematically outline the drawing of the future structure, it should reflect all the rooms and elements of the building.

It is important to provide for communications, to obtain permission for the construction of the building. After that, you can purchase materials.

From the tool you may need:

- tape measure;

- ax;

- chainsaw;

- level;

- marker;

- Bulgarian;

- grinder;

- planer;

- screwdriver and others.

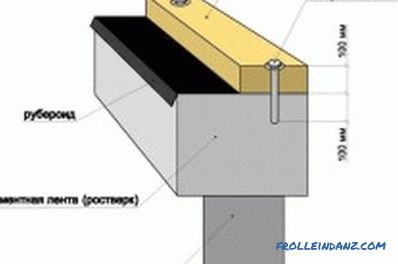

Construction of the foundation: nuances

Scheme of fastening the beam.

It is known that the foundation is the basis of any structure. A well-constructed construction of this sample contributes to the lengthening of the life of the structure. For houses from a bar it is possible to build their following types: screw, continuous, tape, assembly. Here it is necessary to focus on the indicators of the soil.So, clay soil refers to the most problematic base. It is characterized by instability, the ability to freeze, squeeze, blur. The main difficulties associated with high rates of groundwater. Building a foundation, it should be made below the limit of possible deformations.

Water seeps through the sandy soil, but such soils are able to subside, especially if the load reaches its maximum performance. The presence of such rocks gives rise to the foundation at a considerable depth.

Sugar and loam look like a composition of the above layers. The task of the builders is to determine the quality of the clay. Its poor performance is not the best effect on the object being built.

Rocky soils are among the best soil samples. This surface allows you to build on it any structure. In the gravelly soil there is a large number of stone fragments. As a result of this, the rocks are not subject to strong erosion and swelling.

Houses built from glued laminated timber can last for half a century. In the construction of such structures should pay attention to the quality of the source material. Use in the construction of raw materials of inadequate quality will eventually lead to damage to the whole structure. So that the wood is not subjected to putrefactive processes, for this purpose use special safe antiseptic solutions.

Walls: recommendations for their construction

Laying scheme for timber.

All parts of the structure from a bar are strengthened by dowels. Holes are drilled along the edges; fasteners are installed in them. The edges should be cut half and fastened to each other, the result is a butt joint. As you know, the beam is laid according to the method of puzzles. Pre-treated material does not require external cladding.

The required openings for doors and windows are formed when the walls are built. Very well in log houses look openings of wood. You can replace them with PVC structures that mimic the exterior of wood. When purchasing metal doors, you should take care of their insulation. Problems with this part of the work usually does not arise, there are a sufficient number of ready-made kits for sale.

After the above works, you can proceed to the construction of heat and waterproofing, and then begin to lay the roof. As facing materials often use slate, a professional flooring, a metal tile.

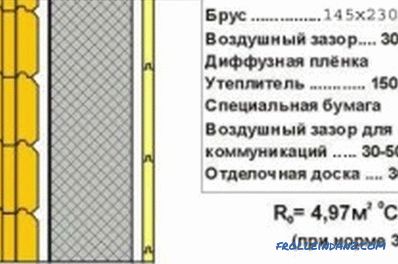

Warming scheme for a log house.

And what about the heating system and communication? Water supply at home can be autonomous or centralized. The second option seems to be cheaper if there is a trunk pipeline near the site.

In order to carry out sewage, a pit is made in the corner zone of the plot into which the tank is mounted in the form of a drum without a bottom. From such a well, a trench is being dug through to the house. The container is closed with a lid, then powdered with earth. Its volume depends on the type of soil and the amount of fluid passing through it.

As for electrical wiring, it is done under a layer of cladding material or in special boxes. The appliance for heating is placed in a separate room. Most often it is fixed in the basement, here are filters, water heaters and other equipment.

Thermal insulation of a building and interior work

Any structure made of timber requires its warming, as at low temperatures the wood cools quickly.

Insulating activities are carried out both outside and inside the building.

Scheme of a gable roof of a log house.

For this, the insulation layer is covered with drywall. Applying external warming, it is possible to change shape of a structure beyond recognition. The heat insulation layer is covered with a decorative coating.

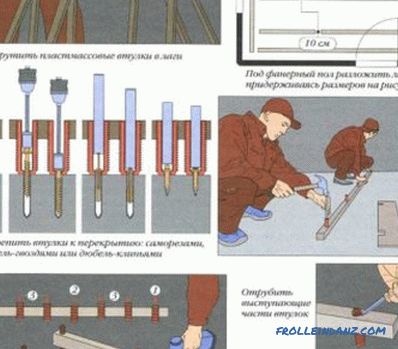

The floor and ceiling are supplied with a waterproofing layer. When the foundation is located at the zero boundary relative to the soil, a two-layer floor is used as a warming component. Building a house on 2 floors provides a basis for compacting structures of a horizontal and intermediate nature. As a cladding material for the walls use drywall.

Is it possible to build a bath from a bar?

A similar technique is used for the construction of a bath. The template is being prepared, the marking of the bars is done. Special strips are laid on the foundation, wooden beams are fixed on them. Once the first crown is installed, it is possible to fill the existing gaps with foam. At the end of the bath drilled holes for nog. After laying the bars, these parts are clogged, the second crown is connected to the previous one.

Other crowns are fastened in the same way. Do not forget about caulking seams, for this is taken any material and the necessary fixtures for work. Preference is given to natural raw materials.

When compared with log buildings, log houses have a number of positive characteristics, namely, higher base quality.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building with serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.