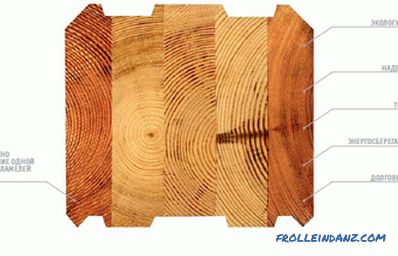

Many centuries ago, Japanese masters first used the technology of bonding bamboo and wooden plates to give strength and flexibility to the handle of rifle bow. Thanks to this idea, the modern building materials market can offer the consumer one of the most high-tech products in the field of wood processing - glued laminated timber.

Advantages of laminated veneer lumber.

Its cost is hardly suitable for low-budget construction solutions, but compared to the quality characteristics of a conventional bar, this price is fully justified. Despite the fact that the glued structure has more advantages than minuses during operation, it has disadvantages. They are not so significant as to influence the decision on the acquisition, but it is better to get acquainted in advance with possible sharp corners during construction or furniture works.

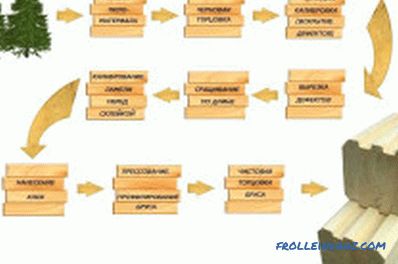

Production technology of laminated veneer lumber

How this production is carried out is worthy of familiarization in order to better understand the advantages and disadvantages of laminated veneer lumber can manifest during its use. In this production, wood (usually coniferous varieties), carefully sorted and sawn into boards, is aged in drying chambers until the required moisture values are achieved.

Production scheme for laminated veneer lumber /

Then the raw material is machined, all possible defects are eliminated, and another quality is sorted. After that, a toothed profile is cut along the long side of the boards, and gluing of blanks on special equipment takes place.

The advantage of this technology is that the product acquires increased strength and shape stability, while possessing insignificant weight. The cube of finished products weighs almost 2 times less than the same amount of ordinary timber. During the construction of the building, this significantly reduces the load on the foundation and the cost of its construction. Such advantages as the ability not to undergo deformation, not to shrink and to resist ignition at the level of metal structures, complements the high environmental friendliness and immunity to aggressive chemical environments. All these advantages relate to products whose manufacture was carried out in compliance with exact technology. Nevertheless, weaknesses in this building material are still present:

- high cost;

- difficulty finding a reliable manufacturer;

- due to the recent appearance on the market building materials - the lack of information about changes in properties during a long process of operation.

Disadvantages of glued laminated timber

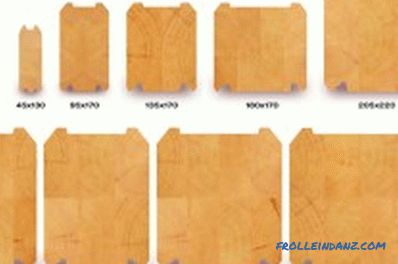

Types of glued bars with dimensions.

The high cost of this material is indeed its negative side. But this is explained by the costly and very complex manufacturing process, which includes many technological steps. All of the above advantages may be absent in products of unscrupulous manufacturers using low-quality wood, saving money on adhesives and time on the process of drying wood. Poor qualifications of employees and poorly adjusted equipment can lead to a violation in the locking joints, incorrectly chosen raw materials - to the appearance of cracks and deformation. Compression of boards with an unusable adhesive composition, which can also cause allergic reactions among the inhabitants of the dwelling, leads to the same consequences.

Therefore, you should purchase only certified products of well-known and proven manufacturers, then it will have all the insulating, strength and environmental characteristics.

When drying, wood tends to change its radial and planar dimensions unevenly, and this can lead to the appearance of delamination and deformation of the cross-section of the glued beams. In the manufacture of this building material has the optimum moisture parameters, but by the time it reaches the customer it has time to be exposed to the effects of weather and swell somewhat.

This can lead to its further shrinkage, as well as the appearance of negative fungal processes in wood. Preventing such consequences will help treatment with antiseptic agents, which for years to come will provide protection from rot and mildew caused by harmful microorganisms.

Didn't find the answer in the article? More information on the topic:

-

What is a construction carriage

Information about what a carriage in the construction and construction of a flat-carriage houses using the Norwegian logging. Advantages and disadvantages of the monitors house.