Sliding gates can be called the most popular type of gate today. Previously, not everyone could acquire such a design due to the high cost of both fittings and other elements of such gates. Today, their price is much more affordable. The advantages of such gates - practicality and durability. But since this is a complicated technical design, it is better to provide installation of the gate to professionals. If you are confident in your abilities, have some construction skills and tools, then installing a sliding gate with your own hands will not be fraught with many difficulties. Moreover, you can save on hiring specialists. The main thing you need is to take into account technical requirements, selection of components, compliance with regulatory loads and following the instructions. Let's take a closer look at the installation process.

Elements and accessories of the gate

Elements and accessories

Elements and accessories

In essence, having everything you need to do the work, you will be easy to install the gate. Especially deep knowledge in construction you do not need enough basic knowledge, material and follow the recommendations of experts.

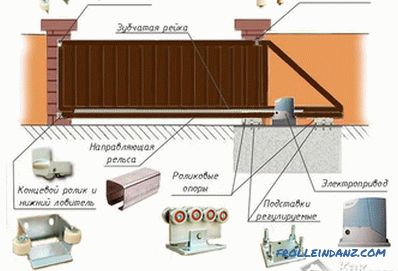

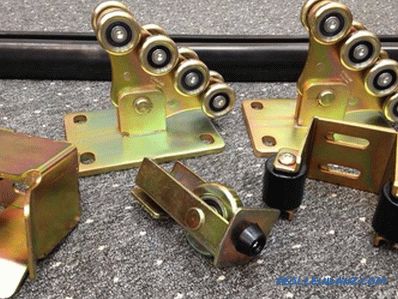

For work, you will need consumables, but the main and important part of the elements is the hardware responsible for the movement of the gate. It consists of:

- roller carriage or carriage (2 pcs.);

- lower and upper catcher;

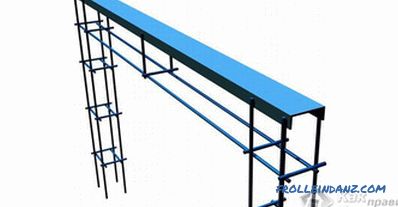

- guide U-shaped beam;

- toothed rack;

- removable end roller;

- upper retainer with rollers;

- plates for fixing the roller carriage.

Pay attention to quality

Pay attention to quality

When choosing quality fittings, pay attention to proven manufacturers, considering the price and quality of products. You can also ask for help from professionals who will help you choose the best option.

It is much easier to buy a ready-made set of gates with all the necessary elements that you only need to assemble and install into place. It has a special installation instructions, thanks to which you can easily do all the necessary work.

Work plan

Foundation plan

Foundation plan

Then you can learn all the nuances by installation of sliding gates in order. First of all, it is necessary to determine the scope of work, among which:

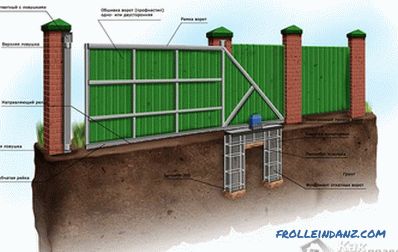

- Digging of trenches and foundation construction. Sliding type gates are quite heavy, so you need to make a foundation for smooth and proper operation.

- Wiring, if you want your gates to open independently of the drive, or if you plan to install a video camera on them.

- Installation of roller elements.

- Installation of the gate on the rolling mechanism. At this stage, you need to hang the gate without adjustment.

- Fastening hardware that catches the shots on target.

- Final gate adjustment.

- Automatic connection, if available.

Plan everything carefully

Plan everything carefully

If you want your gate to serve for a long time and without interruptions, you need to strictly adhere to the plan and follow the instructions carefully following each step.

Trenching and foundation preparation

Foundation preparation process

Foundation preparation process

First thing for you you need to perform preparatory work for the device foundation. Start with trench planning. To do this, follow the following tips:

- From the border of the gateway, retreat a distance that is half the width of the entire passage. For example, the width of your passage is 4 m, then the length of the foundation will be 2 m from the border.

- The trench width depends on the width of the structure of the gate itself. For example, the width of your gate is 20 cm, then you need to dig a trench 10-15 cm wide more in two directions, that is 40-50 cm.

- Depth is a subject of controversy for specialists. Some say that it is important to deepen the trench below the level of freezing, others - that this factor does not affect the future foundation at all. According to the first, the foundation should go deep into 1-1.5 m, according to the second - 0.5-0.7 m will be enough. What depth you choose, especially your decision. We recommend doing it no more than 1 m.

After you have decided on the dimensions, dig a trench in the right place with a shovel. You should get the same as in the picture below.

Prepare the mortgage element

Mortgage

Mortgage

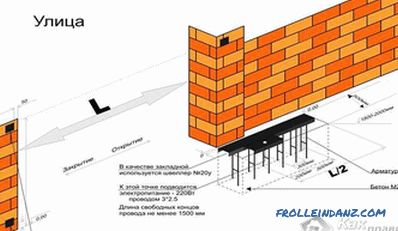

To make the mortgage item, you will need:

- a channel 18-20 cm wide (it can be replaced with a corner of the same dimensions),

- fittings Ø 12-15 mm;

- welding machine.

Installation of the mortgage

Installation of the mortgage

The stacking element is a construction of channel and reinforcement, which The future is installed in a trench and will be concreted. Take a metal channel and cut it to the length of the entire trench. If it is 2 m, then the channel should be 2 m long.After that, it is necessary to weld reinforcement to it in order to form a metal frame. The length of the bars of the reinforcement should be greater than the depth of the trench by 5-10 cm so that it can be drowned in the ground. How exactly you will weld the reinforcement depends on you, there are no restrictions here, it can be boiled in 15 cm steps. The main thing is that the frame is strong, has a vertical base, which is connected with jumpers.

Instead of reinforcement, you can take a different type of metal product, for example, corners.

Once the frame is ready, it can be installed in a trench. But before that, the bottom of the trench should be filled with sand or fine gravel and tamped down by making a cushion for the foundation 5 cm high. Flush the reinforcement so that the channel surface is flush with the road surface. With the help of the construction level, set the frame perfectly smooth. If there is a strong bias on either side, remove the frame and fill the sand in that place. If the mortgage is placed unevenly, this will prevent the gate from moving correctly.

At the same level with the road

At the same level with the road

The foundation must be at the same level with the road. Ground clearance can be no more than 5 cm, so that in the winter, you do not have problems with use.

Wiring electricity

Electricity is running

Electricity is running

If your gates are equipped with an automatic opening and closing of the gate, or they need to install video surveillance , you need to take care of laying electrical cables. They must be carried out immediately before pouring the foundation. The cable is placed in a special corrugated hose and laid in the foundation structure. You need to decide in advance on the place where the drive will be installed, and lead the wires there. The free ends of the wires need to bring above the basement at 1-1.5 m. In order to do everything yourself, look at the diagrams and drawings of electrical wiring for sliding gates.

Foundation Pouring

Install the formwork and fill in

Install the formwork and fill in

Once you have laid the wiring Mortgage element can be poured concrete mix. To do this you will need cement mark M400, sand and gravel. The proportions are as follows: for 1 kg of cement you need 3 kg of sand and 4-5 kg of crushed stone. Water should be half the weight of all components. It turns out:

1 + 3 + 4 = 8

8/2 = 4

The total is 4 liters of water per 1 kg of cement, 3 kg of sand and 4 kg of crushed stone. Knead the required amount of solution and fill the trench. It is important that the channel surface is not concreted completely, the concrete must be at its level. Now the foundation must be left to dry. It will take 3-5 days, for which it will get stronger and will be reliable enough for further work.

Assembly of the door leaf

Assembly of the gate

Assembly of the gate

To make a frame for the gate, You need to have the skills to work with welding machine , since all elements need to be welded together. If you do not have experience in welding, you can ask for help from a friend or in a special workshop, where according to your drawings you will make the frame of the gate.

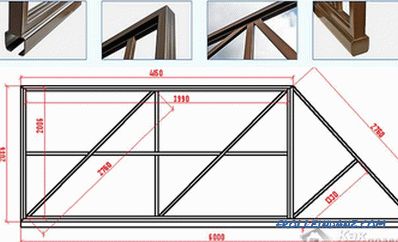

Layout for assembling the frame of the canvas

Layout for assembling the frame of the canvas

To make the door frame, you need to purchase profile pipes. Their size will correspond to the desired size of the gate. There are many variations of designs that you can do. The main thing is to choose the right one for you, cut pipes of the required size and perform welding works. Professionals are advised to cook the frame so that the horizontal cross member was on top of the vertical pipes. Due to this, you will prevent corrosion, you only need to block the horizontal pipes. When the structure is ready, the joints must be cleaned and the frame covered with protective paint.

If your gate is larger than 1.5 m in size, in order to strengthen the construction and prevent sagging, you need to weld cross-pieces in 50 cm steps.

At this stage, the lower pipe should be welded guide U-shaped beam, through which the movement of the gate will be carried out. After that, the frame is sheathed with a profile sheet.

One of the options for how to make a portal frame is presented below.

Installation of roller trolleys to the channel

Installation of roller trolleys

Installation of roller trolleys

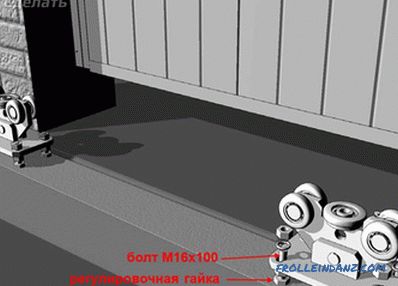

Roller trolleys can be call the most important mechanism, since they must withstand the load of the whole structure, therefore, they should be fastened to the channel as reliably as possible. Plate for mounting rollers must be welded to the channel. They do everything as smoothly as possible and in the same plane so that the gate can move freely. To set them straight, you can use a laser pointer or a tensioned cord. Another option is to draw a parallel line on the foundation, which will be a tangent line to the edge of the plate.Weld the plate should be in the middle of the channel. To do this, retreat 15 cm from the edge, closer to the opening and fix the first plate. The second plate is mounted on 10 cm from the opposite edge.

Installed roller bearing

Installed roller bearing

Now you need to fix the roller carts on the plate. They are usually connected with bolts and nuts. Tighten them to securely and install the gate. Check the smoothness of the course, take control measurements and adjust the position of the roller bearings to expose the gate perfectly smoothly. To do this, you can use the cord, which must be pulled along the opening line of the gate, at a distance of 20 cm from the surface and 3 cm from the second pillar. The cord will serve as a guideline to help expose the gate perfectly smoothly.

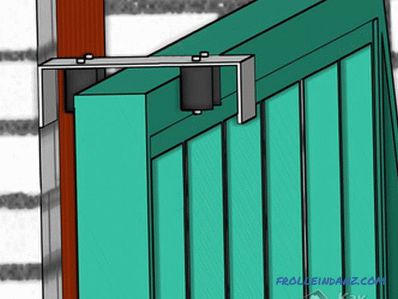

Installing the upper retainer

Upper retaining

Upper retaining

So that when the gate is moving, they pulled out, on top of the pole set the latch or guide. He will stop the gate and not let them swing in strong winds. To do this, on the support pole should note the holes for mounting. Measure everything correctly so that the upper frame without obstacles can enter the retainer.

On the pole you need to install the bracket for fastening the guide. If you fix it in concrete or brick, use an anchor with a stud diameter of 10 mm. If you attach it to the metal, then fit the special screws. In a case when welding is applied, rollers need to be removed.

After securing the lock, check it. The gates should walk smoothly, keep upright, and the rollers should hold them tightly.

Clamps are different, roller or in the form of a conventional bracket. Which device to choose - your decision.

End roller and caps

End roller

End roller

Bottom by the end of the guide U-shaped beam, in its front part, you need to fix the removable end roller, which is inserted inside the profile. It is fastened easily, by means of a bolted joint. On the opposite side you need to install a cork (plug) or the same clip.

This roller is needed so that when the gate closes, the guide rolls onto the catcher located on the bottom, which will be mounted on the post on the other side. Thus, you can reduce the load on the support plates that hold the rollers on the foundation. Plugs or plugs are an obstacle to snow, rain, dirt and debris that can penetrate the guide rail. If not, then the roller carts can quickly fail, and the gate will not open smoothly and easily.

Attaching the upper and lower trap

Trap

Trap

To fasten the lower and upper trap, you need to close the gate all the way. At the pillar, mark the places where the frame of your gate ends. In this place, above and below, you need to secure the mortgages, to which the catchers will be attached. Depending on the mortgages, they can be fixed by welding or bolting.

The catchers will soften the contact of the door frame with the support rollers, as well as minimize the loosening of the structure in strong winds. The lower catcher is also used to reduce the frame sagging, which may appear after a long operation of the gate. At the end, check the installation of your gate. Open and close them several times, make sure that the course is smooth and even.

Installation and connection of automatic equipment

Automatic installation scheme

Automatic installation scheme

If you want, In order for your gates to automatically close and open, you need to purchase special equipment and install it.

First of all, the installation plate to which the drive will be connected should be welded to the channel bar. Usually such a plate is included. For welding, you can use the profile pipes, which are welded to the channel, and then the plate is welded to them. After that, the engine itself is installed on the base and fixed with the help of bolts, which are also included. There are adjusting screws on it, thanks to which the engine can be adjusted up and down, left and right.

It remains only to weld the toothed rails to the U-shaped frame. There will need patience and accuracy, as the slats should be welded so that they are as one. Then, when driving, you will not hear any other knocks of the gate. Then adjust the drive so that it easily drives the gate into action. It remains only to configure the mechanism according to the manufacturer's instructions.

That's it, after all the manipulations your gate is ready for operation. You can be proud of yourself, because they themselves were able to do such a great job. Properly installed gates will be quite reliable, and their lifespan will please you.

Video

Watch a detailed video instruction for installing sliding gates:

Another video instruction: