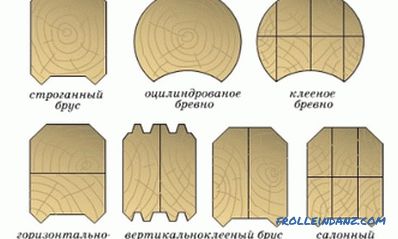

It is possible to build a log house from a bar for the purpose of both permanent residence and temporary residence. The frame is built from such a building material as a bar, and glued. If you plan to permanently live in a house of timber, then the building material should be planed, and if for temporary it is not necessary. In any case, the beam is laid with the cut side inward.

Scheme of species and cross sections of the beam.

Features of log cabins from a bar

Collect the bars with your own hands, unlike log walls, should be directly onto the finished strip-type foundations. Houses or log houses built from timber are sure to shrink, which precludes laying the walls immediately after the construction of the house. Usually they wait at least about a year or two years in order to lay high-quality walls that will serve for a long time. Such a building material, like timber, has only positive characteristics.

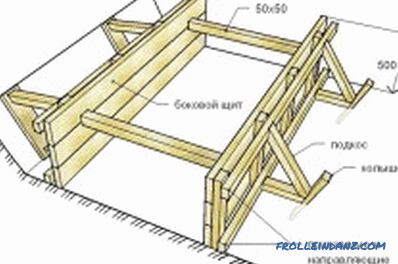

Figure 1. Scheme of assembly of shields for the base.

You can use a profiled bar, saving on finishing materials. A timber can retain moisture in its structure for a long time, therefore, the drying of a built house takes a long time. To build a log house alone should not be necessary to invite an assistant. The process of building a house from a bar with his own hands is not complicated.

To build a high quality log house, you must use wooden dowels, which you can easily make with your own hands. For this purpose, conventional boards or their trimming, remaining after performing any work, for example, related to the installation of the batten, are used. It is better to carry out dug-holes from harder trimming of boards, for this on the one hand they are faced with a saw. Then sawn into boards having a width of 120 mm, the main thing is that they should be smooth.

How to lay the foundation for a log house from a bar

Principles of strip foundation construction

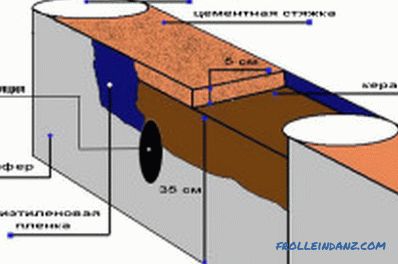

Figure 2. Layout of the ventilation foundation arrangement.

The first step to start the construction of the timber is laying the foundation. Before performing the work, an analysis of the soil at the construction site is carried out, which is reduced to geological studies related to the search for the groundwater level and the determination of the soil composition.

For each type of terrain with a certain groundwater composition, special types of foundations are provided that will serve for decades, and the presence of groundwater will not have a destructive effect on them. Before starting laying the foundation for a log house, it is necessary to dig a trench for the future structure. This is due to the removal of the fertile soil layer. First, sand is poured into the trench, which is compacted by pouring it with water. After that, stone is poured into the trench to begin to reinforce the foundation.

Reinforcing with rebar can be both in the upper part of the foundation and in the lower part. This will give the highest durability of the entire future log construction. Reinforcement is carried out with the use of concrete, if you do it yourself in a concrete mixer, then it will not be as expensive as if you buy ready-made concrete in a hardware store. Delivery of concrete is carried out by such a mode of transport as a mixer truck, and it can only drive into areas with the largest area, otherwise the concrete will have to be unloaded in another way.

The best option would be to use a concrete mixer installed on the site. This will allow you to independently prepare a concrete solution for the reinforcement of the foundation, but the quality of the composition will not be as high as that of the finished concrete. At the bottom of the trench with sand and stones lay reinforcement, and then pour this space with concrete. The whole tape of the foundation, if it is tape, is poured with concrete to the ground level. The foundation can be arranged with the use of formwork, as well as a columnar view of the foundation with a certain composition of the soil.

Figure 3. Scheme of the reinforcement cage for the foundation.

When using a concrete mixer, it should not be closed in the place where the engine is located, as constantly cooling air is required to cool it after and during operation. Before the construction of the log house from the beam after the complete foundation of the foundation should take place from a week to a month for the construction to fully survive.

For a certain type of soil, for example, wetland, it will be necessary to make a spatial framework. Only after that create a formwork and pour concrete solution into it. If the foundation is laid in warm weather, then its surface should be laid out with sawdust or other material, for example, moss, roofing material. You can simply fill it with water. The thickness of the formwork boards should be about 40 mm. It is necessary to choose shields for formwork of the required height and length.

Foundation plinth

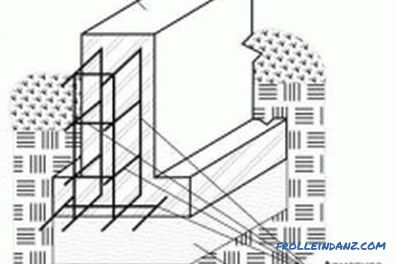

The distance between the plinth center lines is usually taken as the initial size of the shields. Shields are assembled directly on the ground using special pads. The assembly scheme of shields for the base is shown in Fig. 1. Shields with the smooth side must face the inside of the base.

Special windows for ventilation should be provided in the basement of the foundation, which are 15–20 cm from the ground. They are located on opposite sides of the basement construction, each opposite to the other. To create them, you can use asbestos-cement pipes, adjacent ends to the shields, as shown in fig. 2. This position of the pipes will allow not to fill the ventilation holes with concrete solution.

Figure 4. Methods of connecting the beam.

The reinforcement frame of the basement is placed in the upper part, as shown in fig. 3, the concrete screed is then cast. Armature rods should be laid in an overlapping manner, tying them with wire.

In this way, you can get a rigid structure that is firmly connected to the foundation of the future structure. Starting to do the pouring of the concrete solution in the formwork, on the boards it is necessary to mark the fill line on top. When the base of the log house is ready, start laying the first crown.

To properly lay the top trim on the basement, roofing felt is lined in two layers, taking into account the entire perimeter of the structure. To do this, the strip of ruberoid bent along, and then laid on the base. To make a harness, use even bars, on which there are no cracks, various hops, rot.

How to build a log house correctly from a bar

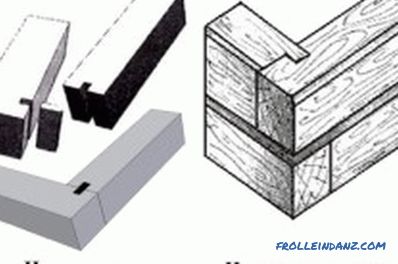

To protect the gaps between the bars from water ingress, you should remove the chamfers from the upper edges, which will be 10x10 mm in size. Connect the corners of the log should follow the thorn-groove method. It is possible to connect the timber on the keys and on the main spike, as shown in fig. 4 as a diagram. The connection of the corners of the initial crown can be carried out in a half-wood method, and the fastening of the subsequent rows is carried out on the keys using the root spikes. The main tools and materials for construction are:

- timber;

- saw;

- hammer;

- pins;

- nails .

Figure 5. Different ways of fixing beams and logs.

There may be gaps between the rims of the bars, so you should lay them with heat insulating material caulk. As a heat insulator, use felt or tow, cut into strips, whose width is 20 mm less than the size of the beam width.

For a better drainage of water from the seams that run horizontally between the bars, they cut a chamfer from 20 to 30 mm wide. To reduce the degree of conductivity between the bars is possible through the use of grooves, stuffing rails in the shape of a triangle.

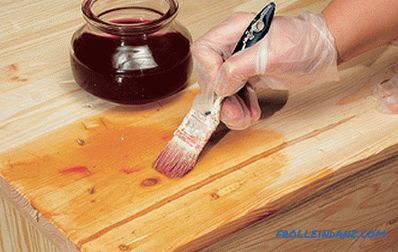

Using pins that have a rectangular or round shape, it is possible to dock the bars in a vertical position, as shown in fig. 5. In order to disinfect all the bars, which belong to the first crown, this is carried out by lubricating each of the bars from all sides. The ends of the bars leave without treatment composition.

Sawing curved boards with your own hands should be done by creating small pieces of them that fit into the window openings and door openings. Oil-treated bars are placed on the base, fastened with staples. It is possible to construct block walls similarly to the process of building log walls.

The cobbled walls have seams which are arranged in a horizontal direction, which is the main difference between log houses from logs and log buildings.

The seams are the most vulnerable parts of the walls of a log house, so they need not only to be warmed, but also to be coated with linseed oil or oil paint.

The bars of a log house can be protected from biological effects on wood, as well as atmospheric influence, by covering the wall of the bar from the outside with a plank or facing brick.

The plank horizontal wall lining facilitates the laying of the heat insulator. If the wall thickness is less than 150 mm, then additional heat insulators are used, and if the thickness is about 200 mm, then you can do without heat insulators.