The name of the sandwich chimneys is due to the features of the device of their pipe, which is a combination of internal and external channels with a layer of thermal insulation laid between them. All those who would like to learn how to connect a sandwich pipe should definitely be familiar with their design.

Chimney construction

Chimney specifications

Chimney specifications

The main differences between chimney products from different manufacturers associated with the technical characteristics of the pipe channels and the type of material used as a thermal insulation strip.

In most products of this class, the inner pipe is made of stainless steel, while the material for the outer pipe channel is usually more expensive copper or brass. In addition, these structures differ in the diameter of their constituent pipes, as well as the thickness of the insulation layer. Chimneys in different versions may also differ by the temperature conditions in which their normal operation takes place.

Mineral wool is used as insulation in sandwich constructions, which by its physical characteristics resembles the well-known asbestos fiber.

The thickness of the heat-insulating gasket made of cotton can be from 30 to 60 mm, which provides the necessary stability of the structure to the effects of aggressive media and elevated temperatures.

Sandwich chimney

Sandwich chimney

Among the undoubted advantages of sandwich chimneys are their following remarkable properties:

- reducing the likelihood of condensation to a minimum;

- low pollution of the chimney with soot;

- increased level of fire safety;

- attractive design;

- low weight design.

The lightness of the construction of a sandwich-type chimney eliminates the need for foundation, which is another confirmation of its undoubted advantages.

Installation preparation

Arrangement of the opening in the ceiling

Arrangement of the opening in the ceiling

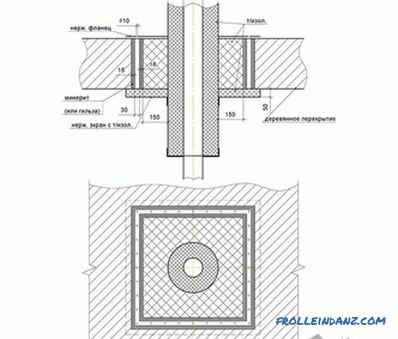

Preparatory measures in this situations are reduced to the protection of the passage of chimney through the interfloor overlap. For the safe installation of pipes in such areas, a special structural element is used (the so-called "through-hole"), the installation procedure of which is as follows:

- Before installing the nozzle, the latter must be carefully prepared (closed outside with a layer of thermally insulating material placed along its walls).

- After this, the inner cavity of the nozzle is insulated and prepared for installation. For this purpose, the marking of the place of its laying in the ceiling is first made, and then an opening of the required size is cut.

- Immediately thereafter, in the zone of contact of the nozzle with overlapping, the outer insulating layer is laid, after which the nozzle itself is mounted.

- For the purpose of additional heat removal between the pipe and the main pipe, it is necessary to provide a small air gap.

Joining of the chimney elements in the places of their passage through the ceiling is strictly prohibited.

Chimney Assembly

Chimney Assembly Scheme

Chimney Assembly Scheme

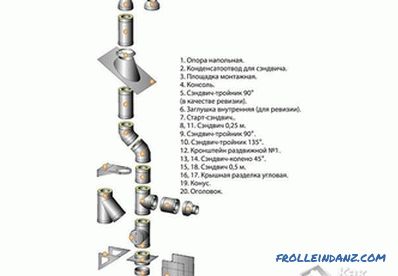

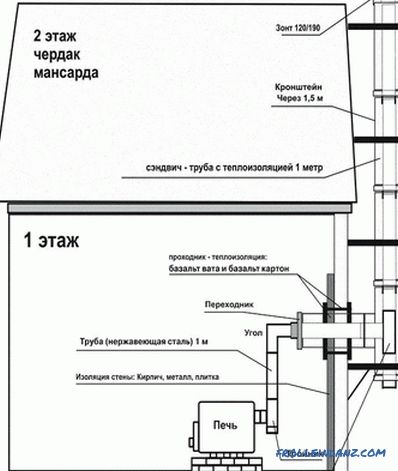

Chimney Installation Features We suggest you consider a sandwich with your own hands on the example of a two-loop system well known to most builders.

Installation of the structural elements is carried out from the bottom up, i.e. from the heat source towards the exit of the chimney.

When assembling, the next section of the inner tube is inserted into the already mounted part, while the outer billet is simply put on the previous one. A similar order of assembly of the structure will allow you to protect the chimney duct from the ingress of foreign moisture into it.

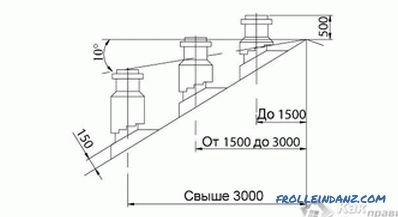

It should be added to the above that when installing the sandwich chimney, one of the options for placing the exit part above the roof plane can be chosen.

Chimney pipes on the roof - scheme

Chimney pipes on the roof - scheme

Features of installation

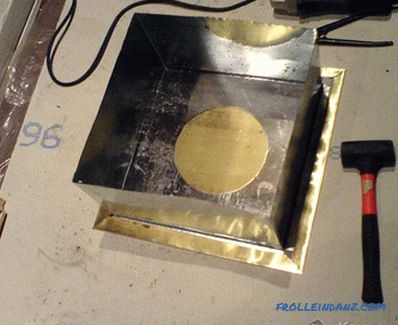

Cover for

Cover for

floors When installing the flues of the type we are considering, a number of features of the following plan should be taken into account:

- Sealing of the main channels is ensured by using a special sealant designed for a temperature of 100 degrees.

- For reliable fastening of all structural elements (pipe bends, tees, etc.), clamps of a special form are used. To fix the chimney base on the wall, typical brackets are used, usually installed every two meters.

- The length of the horizontal sections of the chimney construction should not be more than 1 meter.

In order to ensure the possibility of regular cleaning of pipes from the accumulated during operation of the burning chimney should be equipped with a special hole with a door (the so-called "revision").

Video

For detailed instructions on installing a sandwich chimney and its features, see the following video:

Photos

Chimney internal installation scheme sandwich

Chimney internal installation scheme sandwich

External installation scheme of the chimney

External installation scheme of the chimney

Chimney pass through the ceiling

Chimney pass through the ceiling

Elements chimney sandwich

Elements chimney sandwich

Chimney in the ceiling

Chimney in the ceiling