Lumber made from natural wood is often used for construction. They can be classified by type of wood, forms of procurement and other parameters. Characteristics of lumber depends on a number of properties of a particular type of wood.

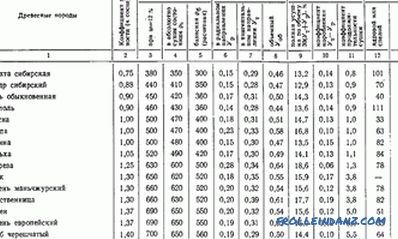

Table of characteristics of sawn timber.

Lumber classification

Each type of wood has its own properties. That is why it is customary to observe a convenient and understandable classification. All materials from natural wood can be divided into several groups:

- Bars are mostly rectangular in shape. The characteristic of such materials implies that the division in the group is carried out according to the form, method of manufacture, according to the size of the section. The section is usually performed from 100 mm and more.

- Boards can be divided into edged / uncut, sawn. The last group is divided into clean cut, with a blunt wane (blunt and sharp).

- Rivets are used for barrels. The group is limited, includes riveting with a cylindrical or blunt section.

- Boards and slats, sleepers are materials that are small in size and have a rectangular cross section. Their thickness and shape may differ slightly.

- Reiki is an unedged board, the edges of which are processed. Three sides of the board are uncut, and one is sawn.

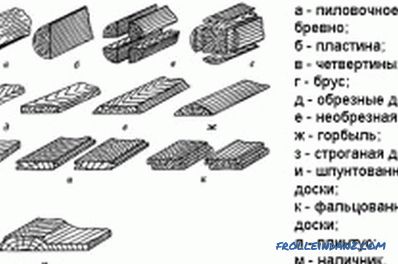

Lumber Classification and Characteristic:

Timber Types Scheme.

- By type of surface treatment. Timber can have surfaces wide (layers), narrow (edges), end (ends). In turn, the broad can be divided into external and internal.

- By the type of sawing wood. Relative to annual rings sawn timber is classified into radial, tangential, mixed.

- By type of wood. All sawn timber can be made of different wood species, each of which is best suited for specific purposes. Pine is leading in this area, it is possible to make various kinds of products from it, including for covering walls and roofs. Fir-tree, larch, cedar, fir are used in construction. All of them are great for boards. But ash, oak, mahogany are applicable for the manufacture of finishing materials, as joinery, where they fully disclose their qualities. Aspen is great for finishing the interior walls of saunas or steam rooms, it is excellent in resisting the negative effects of moisture and sudden temperature changes. For flooring and natural wood flooring experts recommend the use of birch. Here she fully reveals her potential.

Before you buy one or another type of lumber, you need to study their characteristics, areas of use. In this case, the selection will be correct, and the wood itself will last a long time.

Timber options

Lumber classification scheme.

Timber that is used for construction can be made of various wood species. The most popular material is needles, most of the boards and boards are made from pine and spruce, but there are other options. Pine, unlike other wood species, is distinguished by its low weight, with minimal stress on the foundation. For example, aspen or birch have a very large weight, but their strength characteristics are not so good. Boards are usually made of pine, this material is very durable, easy to process, has many advantages.

Pine contains natural gum in its composition, which acts as an excellent antiseptic. This ensures the absence of traces of rot, mold for a long time. Pine has a soft and delicate structure, it makes processing simple, pleasant and fast. The smell, the color of pine add material attractiveness not only as a standard building material, but also as an option for decorative wall cladding, the construction of log cabins.

The characteristics of sawn timber are not without such a parameter as the number and presence of branches. Here it is necessary to pay attention to the spruce. This conifer has many positive characteristics, but its processing is complex. The problem is that the trunk contains many branches, and this is an obstacle to processing. Spruce is not as resistant to decay as a pine, but its price is much lower than .

Scheme of options for sawing wood.

Wood such as cedar can also be used for boards. This option is rare, but still used.

Cedar wood is durable, reliable, like spruce, but it is more simple and convenient to process. Fir can also be used to make lumber. It is resistant to decay, perfectly processed, has many advantages.

Types of lumber

Lumber is produced in various forms, it is possible to choose a suitable option. Products differ in shape, size, their characteristics, field of use. Common materials include edged and unedged boards that are suitable for almost any job, but there are other options that act as supporting materials.

Most often, edged and unedged boards are used for construction, they differ in a number of parameters. These lumber are very popular, they are used for the construction of the frameworks of houses, for the construction of strips, walls, partitions, for the installation of roof systems, formwork and other works.

The edging board is a material obtained by cutting a log. At the same time, all its edges are even, but a small amount of bark may remain, that is, a wane. Indicators of moisture resistance, strength, mechanical stability are very different, as well as cost.

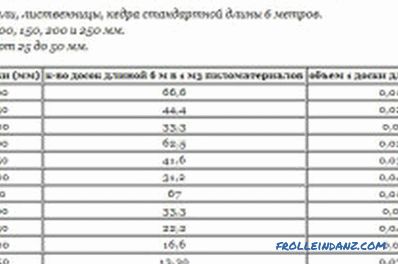

Calculation table for trimming boards.

This makes it possible to choose exactly the material that is suitable for work more than others, without overpaying. For the manufacture of edged boards are often used pine or spruce. The cost of such boards is not so great, but the strength and durability correspond to all parameters. Of these boards, you can safely build not only the outbuildings, but also carry out interior decoration. Timber has a standard size of 6 m, but the thickness and width are different. The width of the boards can be equal to 100 mm, 150 mm, 200 mm, for thickness - 25 mm, 40 mm, 50 mm.

The scope of the edged board is quite wide:

- for the manufacture of the frame, walls, partitions;

- for the flooring of rough, finishing floors;

- for the manufacture of various supporting structures;

- for the manufacture of formwork;

- in the manufacture of furniture;

- in the manufacture of carved furniture;

- in the construction of gazebos, garages, sheds fencing

Unedged board has edges with bark, it is used quite often in construction. The appearance of these lumber are attractive, as close as possible to natural, which makes them an excellent option for wall cladding. Unedged board has a not so high density, so it is easy to any treatment. Finishing such boards does not take much time. But if there are many cracks on the surface, this will significantly reduce the service life of lumber.

Four-edged and clean-cut timber

Timber may vary in price and quality. The cheapest can be attributed chetyrehkantny timber, which is made in large quantities, without requiring for this large costly capacity. The manufacture of timber is carried out by cutting or heaving of solid wood, but the quality of the surface will differ significantly. For example, when weave the sides, we get ragged, which is not always acceptable. When sawing, the edges and edges are neater, such a timber is already suitable for work, where the appearance of materials is important.

A round-cut timber is a square material, oskedanny on all sides. Its length is usually 4 m, thickness - from 100 mm, depending on the destination. Such timber is made, as a rule, from a pine. It is processed on all sides, including the end parts. Used most often for the construction of the walls of the house, beams, ceilings, subfloor. Differs in high strength properties.

The half-edged board and the croaker

The half-edged board has uneven planes, traces of bark may remain on the ends. This board is used for technical work. Bridges are made of it, it can be used for technical and draft floors, as a basis for other products.

Slab is a fairly cheap lumber, which, when properly executed processing perfectly replaces other wood products.

In appearance, the croaker is very similar to the sidewall of a log, its part is propylene on one side and not on the other. Such sawn timbers are considered to be lumpy type waste; they remain after cutting the base material. But the dimensions of the slab are normalized, it has the same width from the ends and along the entire length. Today, two types of croaker are used - wood and business materials. It is used for various purposes, as blanks for other products and building elements.

Lumber is a piece of natural wood. They all differ in shape, their individual characteristics, size, appearance, degree of processing. Lumber is used for construction and repair work of various types, often used in the assembly of furniture, fences, in the construction of draft floors. When choosing, you should focus on those properties that are necessary for specific conditions.