The wood at the base of the walls of the house begins to shrink with time. This leads to the formation of cracks, which should be disposed of, because the building with the grooves between the logs loses its insulating characteristics. To cope with such problems will allow cauldron wooden house, which is sometimes required to produce several times during the operation of the house.

The caulker performs the functions of warming and also protects the wood from moisture.

A caulk, which serves as a warming agent, also pursues related objectives, including the protection of wood from moisture. Its accumulation is due to the collision of warm air masses coming from the house, and cold - from the street. Condensate is very dangerous for wooden walls, as it can cause mold and fungus on them.

Tools and materials

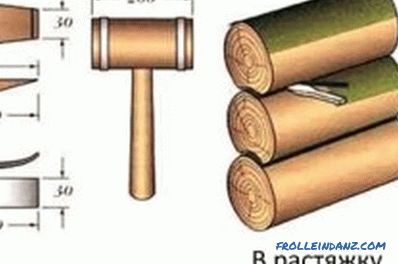

- mall;

- caulk;

- insulation;

- scaffolding.

Choice of material for caulking

In order for the cauldron of a wooden house to be effective, it is necessary to choose a good insulation, which should have a low thermal conductivity. The material must be immune to moisture and temperature fluctuations and must be characterized by wind resistance.

Moss acts as the most successful solution for the caulking of a wooden house.

Select the bioinert material, which will eliminate the interest of insects and pathogenic fungi to the walls of the house. Prefer should be eco-friendly material, otherwise the construction of a wooden house does not make sense. Durability is also important for insulation, it should not be less than 20 years. Among the qualities and air permeability, as well as hygroscopicity. The latter characteristic involves the absorption of moisture and its impact if necessary.

In view of the above requirements for the characteristics of insulants, moss acts as the most successful solution for the caulking of a wooden house.

This material is a bog plant. No wonder it is used as an inter-coat heat insulator, because it is a natural antiseptic. This quality makes it possible to prevent the formation and further development of putrefactive bacteria and fungi, which guarantees a longer life of the wood. Moss is able to smooth out changes in humidity.

Despite many advantages, over time, moss began to look for a replacement, since it is quite difficult to work with this material.

A tow with a caulking iron at home not only warms the walls, but also seals them.

A house can be caulked with tow, which is obtained from flax fibers. The material not only warms the walls, but also effectively seals them. Sometimes tow is treated with resins, which increases its resistance to moisture. When using tow, the caulker will have to be reapplied after some time, since the material contains a huge amount of bonfires, which are gradually shaken.

The process of caulking houses can be made with hemp, which is not afraid of temperature changes and high humidity. This allows the stump to not lose its characteristics even after it gets wet, therefore the heat insulator is resistant to rotting.

Often a caulker is carried out using jute fiber, which is not affected by mold, bacteria and is not of interest to insects and birds. Jute is also hygroscopic, and also easy to compact, which compensates for the high cost.

Technology caulking wooden houses

Caulking machine is made in several stages, due to the gradual shrinkage of the building. The first time a wooden house should caulk after assembly.

The second stage is carried out 1-1.5 years after the completion of construction. The third time the work should be repeated after 6 years, since it is believed that after this period the house ceases to sit down. If it is planned to produce house siding with siding, the 3rd stage of the caulker is not required.

If you are wondering about how to properly caulk, you should be aware that the insulation must be laid with a layer of at least 5 mm.

Methods for caulking wooden houses.

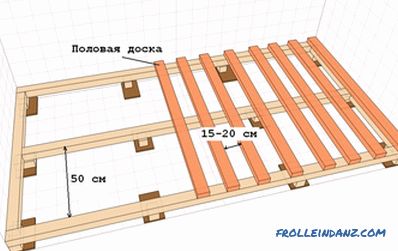

If a caulker is being made after building a house, a heater should remain on both sides of the walls, which should be turned and pushed into the grooves between the logs. Such manipulations should be carried out with a hammer and a tool called a caulker. The hammer should be wooden or rubber. The caulking process should be carried out in several stages, after the first batch of material, which was in the grooves, to use the second batch. Thus, you need to fill the gap, while they will fit the material. If the blade of a knife 15 mm or less can be placed in the groove between the rims, the caulker is made successfully.

It is important to know that it is necessary to caulk a house correctly between the crowns, where rather large cracks have formed. To do this, use jute, from which it is necessary to twist long strands, after rolling them into a ball. Then, from the resulting coil, it will be necessary to dial the loops, placing them in the slots until the latter are filled.

Technology for caulking wooden houses.

In winter, it will be possible to check how well the caulking was done; for this, the walls must be analyzed for the presence of so-called “hares”. They are pockets of frost, located on the outer sides of the walls. These foci are formed on the cracks through which warm air escapes from the premises of the house. In the presence of such "hares" you need to mark their locations to eliminate the grooves between the bars. A year after the cauldron, the house should be inspected in order to repeat the insulation quality. The heat insulator will have to be added to the places where it has worn out or spilled out, in some places the cracks may increase and need to be fixed.

It must be remembered that natural insulation materials are of interest to birds, which is why they should be hidden as close as possible between the grooves.

The house should be caulked from 4 walls at the same time, in the process of which one cannot do without outside help. And in the future, during the work it will be necessary to use forests. The completion of the re-cauldron indicates the possibility of finishing work inside the house.

Before starting work, you should consider some exceptions, which are assumed by the caulking technology. So, moss can be used exclusively for warming a house assembled from a non-profiled bar. This is due to the fact that after laying the named heater will completely fill the interwarns space, which is completely unacceptable if the timber is assembled using a thorn-groove system.

The key to success in quality work is the knowledge of how to caulk properly, so it is important to familiarize yourself with the rules even before the start of insulation.

Didn't find the answer in the article? More information on the topic:

-

How to dry a tree qualitatively?

Recommendations on how to dry the tree yourself. Rules for proper drying of wood. Drying under atmospheric conditions. Advice of experts on drying wood.