Over the past decades, the construction of wooden log houses has become the most common. At first glance, the installation of such houses is not difficult, but it is not. In fact, the process requires that the assembly technology of a log of rounded logs be observed.

A log house is a construction of walls of logs horizontally connected to each other.

Basically, log houses are assembled in the winter season, and walls will be ready by spring. Until the fall, the house should shrink naturally, which requires a warm period. Well, and then you can start the finishing work.

The main characteristics of the assembly of a log of a rounded log

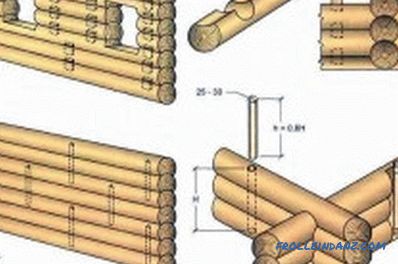

In the construction of a log house is the construction of walls of logs horizontally connected to each other. One laid row is called the crown. The bottom row is the back crown, and subsequent rims are mounted on it. For the very first row it is best to use larch wood, as it has the greatest strength and is the best option for this purpose.

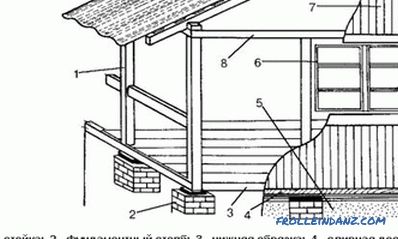

Scheme of assembly of a log from a rounded log on the nail.

A rectangular blockhouse consisting of four walls is called four walls, and if the walls are supplemented with a partition, they are called five walls. In the construction without partitions, the frame is tied only at the corners, and the five-wall has an internal T-shaped connection of the partition with the external structure.

The base of a log of a rounded log is mounted in a horizontal position of softwood or hardwood. For construction, it is recommended to use wood harvested in the winter, and fresh logging, since this material will contain little water and is easy to process, and also has the least shrinkage, deformation and a little rot. If the choice was made in favor of conifers, then the best option would be pine wood, not spruce, because pine logs have a long service life and they have less resin content.

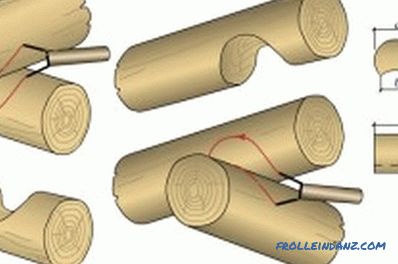

The most difficult to install a log house is ligation of external corners. There are two main types of dressings:

- with the remainder. In this case, the ends of the logs stand for the corners (in the "bowl");

- without residue (in the "paw").

Basically there is no difference between clutches. With the current buildings the most common method of laying "in the bowl."

Required tools

Tools for making a log house.

These are:

- ax;

- plane;

- pencil;

- tape measure;

- square;

- hammer;

- jigsaw;

- hacksaw, chainsaw, etc.

Assembly principles for logs from rounded logs

Before starting to work, the log should be sorted out, and the temperature should be respected. If in winter the temperature is not lower than -30 ° C, then logs can be used with a cross section of 22-24 cm, and in regions with a more severe climate - 26 cm or more.

When choosing logs, it is important to ensure that there are no rotten areas and similar flaws. It is impossible to use logs with visible deformation. If the logs are short, they are spliced using a vertical ridge. To do this, the joined ends of the logs are cut perpendicular to the axis.

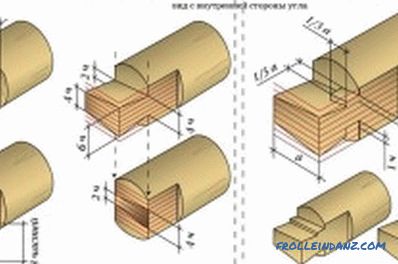

A groove is marked on the log, and on the second - a crest, knocked out with a chisel. The dimensions of the groove should not exceed one third of the cross section of the log. It is recommended that the lower row and the upper crown be selected to the required length; if this is not possible, they are spliced with a tooth at a right or oblique angle.

A groove is marked on the log, and on the second - a crest, knocked out with a chisel. The dimensions of the groove should not exceed one third of the cross section of the log. It is recommended that the lower row and the upper crown be selected to the required length; if this is not possible, they are spliced with a tooth at a right or oblique angle.

It is necessary to re-check the logs in length. The partition inside the log has a connection with the outer wall of a vertical ridge, which is called "frying pans", it has expanded ends. Special grooves should be cut in the logs of the outer wall. When one side of the ridge is made at a right angle, it is called a “half-crock”. Usually used when connecting with a cross.

It is necessary to lay a board impregnated with bitumen, which is 5 cm thick and 15 cm wide, on a ready-made foundation. On the board, a crown is pressed on the underside of the board. The following wreaths are laid, which, if necessary, must be fitted. When laying logs you need to periodically check the horizontal and vertical logs.

Marking and cutting of the log in hand.

Crowns need to be fastened with dowels made of wood, observing chess order, which have a cross section of 2 cm, and a pitch of about 2 m should be observed between them. with an interval of 20 cm, starting from the edge of the pier.

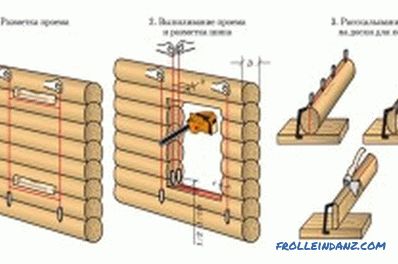

When mounting the rims, you should not forget about the window and door openings, according to the drawing. Laying the overlapping crown, the opening is filmed with a plumb. The ends are processed and end with a vertical ridge.When mounting door and window frames in the openings, you must leave about 5 cm above for shrinkage. It is important to remember that in the opening of the log, both the bottom and the top should not have a comb.

How the house will be installed and the walls will be fully mounted, they will carry out the caulker. For this use tow, hemp, flax or felt. Modern assembly technology involves the use of special materials stacked between logs during assembly. Due to this, it is possible to better insulate the interbranch joints.

As a log frame will be fully installed, it will not be touched for about six months before shrinking. During this time, the log house can shrink by about 12 cm.

It is important to know that pins and spikes should not reach the bottom of the nest 15-20 mm, this is necessary for proper shrinkage of a log from a rounded log.

Preparation of window and door openings in the frame.

But by introducing modern technologies, it is possible to reduce the time it takes for a structure to shrink. It is possible to mount a covering crown through which all studs are passed, with a section of 12 mm and a length of about 1 m. They descend to the ground. At the bottom of the stud, a washer is arranged, which is 3 mm thick and has a nut. But it is necessary to take into account that the stud should not be in contact with the foundation. Subsequent crowns are laid. The stud should be raised tightly, and the nuts should be screwed onto the protruding part - couplings not less than 6 cm long, into which subsequent studs are screwed. After the topmost crown is mounted, all the studs are tightened with a wrench.

If you measure the height of the log house before tightening and after it, you can make sure that the shrinkage has occurred with the logs.

After that, you can continue to collect the frame. Such a house will be durable and will not fall apart even in the event of an earthquake; therefore, this assembly is used in seismic zones.

How to avoid mistakes when installing a log from a rounded log?

Many people can not imagine what the technology of assembly of a log is, all the nuances of the process. This is important to control the installation, since the consequences of poorly performed work can bring a lot of trouble, even to the unsuitability of a log house for housing.

It is important to know:

After the log house has been built, there are unpurified areas of bark on the logs that will start to darken over time, so the log house must be polished.

- The permissible moisture content of the material should not exceed 20%. But there are cases when log houses are collected from logs with high humidity, which is above 60%, which means that the forest was practically only cut down. Such material can lead to deformation and to strong cracking of logs, as well as to the appearance of mezhventsovy cracks and gaps in the castle part. Humidity leads to decay and the formation of mold and fungal deposits. Check the moisture content of the material is not difficult, you only need to purchase a moisture meter. Its price is not so high compared with the losses that may arise during the construction of low-quality material.

- An important factor is the treatment of all wooden structures with an antiseptic, bioseptic and fire retardant, since it will be very difficult to fight mold afterwards, and the fungus can turn the building into dust in a short time.

- Before installation it will be useful to check the logs for straightness. Sagging should not exceed 3 mm, if one exists, then it is better to refuse this material, since it will be difficult to join the crowns. The first crown must be firmly tied to the base, in which the steel pins are pre-laid, and the crowns are pulled together with each other. If the technology is not followed, slots are formed, the frame may become loose.

- It is impossible to allow the crowns to loosely adjoin along the whole plane. To correct this flaw, you will then have to dismantle the entire log house, therefore it is necessary to check the installation from the first rows.

A few words in conclusion

Assembling a log from a rounded log has a decent interior look, and therefore houses do not require additional decoration. Wood material can be coated with a thin layer of varnish, which will perform a protective function from environmental influences and emphasize the naturalness of wood.

Didn't find the answer in the article? More information on the topic:

-

Wooden windows: DIY-making

Do-it-yourself wooden windows: the advantages of installing wooden structures. Varieties of windows from natural breeds. The stages of the manufacture of wooden windows, installation design.