Cheap and warm - with these two words you can describe a home made of expanded clay with your own hands. The method of such construction may be to the liking of those who wish to have their own housing with minimal material costs. In addition, such a project takes less time and effort to implement as compared to brick buildings.

Advantages and disadvantages of the technology

Some are skeptical about claydite, talking about its instability or instability. But even if we do not know something to the end, this does not mean that it is bad. To fully appreciate this building material, you need to know about its strengths and weaknesses.

Ceramsite concrete blocks

Ceramsite concrete blocks

Strong:

- Versatility. The material (speaking of the monolith) can be used in the construction of walls, pouring screed and even partitions.

- Low weight. Component of the final product, in addition to bulk additives, is expanded clay - this is a natural material made of clay, which has air pores.

- Good thermal insulation properties. In many respects, it will surpass certain types of aerated concrete and foam blocks.

- Possibility of independent production. With the observance of technology, the material can be prepared at home.

- Expanded clay has long been used in construction. In many apartments they poured a concrete screed on the basis of expanded clay, which has been successfully used to this day, so we can talk about durability.

- High environmental friendliness.

It has a low density

It has a low density

Weaknesses:

- Low density compared to other types of dense concrete. This may create some difficulties in arranging furniture and equipment after construction.

- The need to provide insulation from moisture on the outside of the building.

- Necessity of the scrupulous approach at performance of calculations.

- Relative fragility compared to dense types of concrete.

- Unpresentable appearance, so the obligatory finish is important.

Finishing needed

Finishing needed

Disadvantages, in principle, can be considered insignificant if we compare how much cost is spent on the purchase and delivery of finished products. The advantages overlap with all the shortcomings. The full picture is needed only to take into account certain nuances in the design and procurement.

Construction Methods

From Blocks

From Blocks

There are two main ways to build claydite :

- block;

- monolithic.

Monolith

Monolith

In the first version, you can buy ready-made blocks or make them yourself. It is important to remember that when making such a decision it will be necessary to use a solution that will necessarily create cold bridges, which will reduce the thermal characteristics by a certain percentage.

The monolithic fill is that a special composition is prepared, from which the walls are erected. There are difficulties, but the design is very durable and resistant to various influences. In this case, you can easily do the work yourself. The time goes a little longer than the block masonry, but the result is definitely worth it.

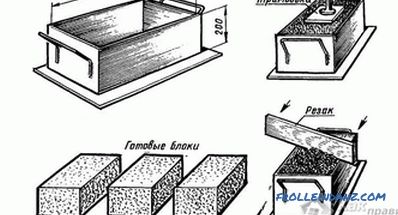

Making blocks

Form for claydite-concrete

Form for claydite-concrete

To start work, you will need a machine, which will be used for the manufacture of blocks. You can buy it at an affordable price or make it yourself. If you own elementary skills with a grinder and welding machine, then this will not be a big problem. Forms do not have to be metal, wooden can also serve for a long time. The dimensions of the final product can be the same as that of a cinder block - 20 * 20 * 40 cm. As an alternative, 39 * 19 * 14 cm or 21 * 51 * 25 cm can be used. For internal walls, the width can be halved.

A mold for the manufacture of solid blocks

A mold for the manufacture of solid blocks

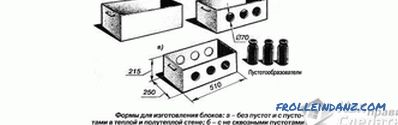

With empty formers

With empty formers

- Metal sheets with a thickness of 3 mm are used to prepare sheets of metal according to selected dimensions, taking into account the wall thickness, adding this value to the length and height.

- With the help of a welding machine a box is made, which will be the form for the blocks.

- Two small parts are made of the same metal, which will ensure the formation of voids inside. Dimensions will be 3 cm smaller than each side, and it should be taken into account that the internal partition in the block should be about 5 cm. compacting their weight blocks. Limiters are welded to the frame, which will not allow it to fall below a certain level - so the blocks will have the same height.

- A 5 cm wide partition is welded in the middle of the frame.

- Handles are attached to the case for more convenient lifting of the whole structure.

- On the long side, you need to fix the electric motor with a weight attached to its rotor with an offset center of gravity, thanks to which the machine will vibrate, compacting the solution.

- To simultaneously produce several elements of a building material, it is possible to make a shape into several blocks.

Expanded clay solution

Expanded clay solution

For the preparation of raw materials that will be put into production, you will need:

- expanded clay;

- cement;

- water;

- plasticizer;

- sand that does not have clay impurities.

The whole process can be accelerated thanks to a concrete mixer. First, water is poured into it and, according to the instructions, a plasticizer is added in proportions, everything is well mixed. Separately, sand, cement and expanded clay are mixed in dry ratios in ratios of 3: 1: 8. It should be a homogeneous mass. After that, the mixture is placed in a concrete mixer and combined with water. If a vibrator is present in the form, then less water is needed to make the solution dryish.

Blocks made in a machine without a vibrator will have low strength.

The molding will occur as follows:

- It is advisable to choose dry and warm weather. Well, if the air temperature is above + 18 ° C.

- The surface on which the building material will be folded must be flat. You can organize such a solution by knocking down the processed edging board into shields or using moisture-resistant plywood. You can simply lay a concreted area with oilcloth.

- The inside walls of the machine must be well polished, in addition they can be lubricated with used oil.

- First, hollowers are inserted (if their design does not provide for their presence).

- The solution is poured in and is well rammed by means of vibration or frame.

- When the composition is set, the form can be removed to start the drying process.

- Full readiness comes in a month.

- After a few days, the building material can be safely transferred and folded for storage.

- It is necessary to cover the finished blocks while they are on the street so that rainwater will not soak them. For these purposes, suitable plastic film, slate or roofing material. It is important to maintain a gap between the elements so that the air can circulate freely.

Calculate the number of blocks

Calculate the number of blocks

Before you start pouring, it is advisable to calculate how many blocks will be needed for the future project. To do this, calculate the area of all walls. This is done by multiplying the length by the width. All results are summarized. Further, the area of the block itself is recognized. After that, the total area of the building is divided into the block area. Knowing the total number of building units, you can decide what amount of source material you need to buy. The weight of a standard unit is 15 kg, if the calculation is made according to proportions, then it turns out that the cement leaves 1.5 kg, expanded clay - 12 kg, the rest is sand. This data must be multiplied by the number of all elements. Based on the number of components, it will be possible to calculate the amount of money that will be used to purchase these materials.

Filling of a monolithic structure is an integral part of the construction of a monolithic wall, therefore it will be described in the appropriate subtitle.

What foundation

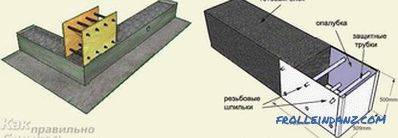

Tape foundations

Tape foundations

For a claydite house, it is desirable that at the base was a strip foundation. It can be shallow or standard. The first option is suitable if you know that the soil in your area has a rocky base and is stationary. In all other situations it is better to make it below the freezing level. Components for pouring it will be river or washed sand, cement and crushed stone.

Device of a classical strip foundation

Device of a classical strip foundation

Device of shallow foundation

Device of shallow foundation

- Estimated area. We need to carefully look where the slope goes. This will allow to make the deepening to the required level and to ensure that the foundation subsequently turned out smooth, and not with surges.

- A string is drawn around the perimeter. It should be located on the outer edge of the planned structure. The width of the foundation must necessarily be greater than the width of the walls. The minimum value for this is 10–15 cm. For more convenience, another thread is pulled along the inner edge, which will also serve as a stop.

- A trench is being dug. Its depth should be lower than the layer on which freezing occurs during the winter period.

- Coarse sifted sand is laid on the bottom.Its layer should be 15‒20 cm. It is important to tamp it well, for additional shrinkage it is poured over with water.

- Rubble is covered with the same layer. It is also important to tamp it well.

- The next step is to install the formwork. You can make it from improvised means. For this purpose, a solid board is used, which is knitted into shields, a polystyrene foam base or plywood, which is covered with plastic wrap, which prevents it from being squeezed.

- The metal crate fits inside. Its manufacture from fiberglass reinforcement is allowed. It must be ribbed, and its diameter must be 12 mm.

- It is important to remember that the height above the surface should be at least 70 cm. This will prevent wetting due to the incoming moisture. If a large amount of funds is required to fill this level, then you can lay out the remainder as a block base.

- The crate fits inside the prepared trench. It is important to remember that its dimensions should be 10 cm smaller in order to ensure its immersion in the solution by at least 5 cm, only in this case a monolithic structure will be obtained, and metal rods will be protected from corrosion.

- At this stage, liners are laid for plumbing, sewage and other utilities.

- All voids during pouring need to be eliminated with a vibrator. From this will depend on the maximum strength.

- To facilitate further work, you need to try to bring the top edge to the level. It will be much easier to lay.

- With a strong hurry in two weeks, you can move on to the next stage, but it is advisable to give a month for the concrete to gain full strength.

- At the same time with the foundation, a blind area can be made. She should be leaning away from the house. Its purpose is to provide a rapid outflow of rainwater from the basement, as well as giving additional strength to the base.

The blind area

The blind area

In hot weather it is important to provide good hydration so that no drying and cracking of the base occurred. To do this, you can cover the plane with a ruberoid or plastic film. Periodical wetting with water will be useful.

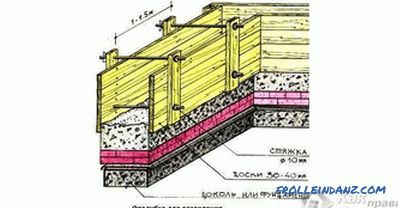

Monolithic walls

Such an option with the right approach will be of sufficient strength. You should start with the preparation of formwork. It is on how well it will be made that the final result will depend. At this stage you should not spare money. It is necessary to purchase waterproof or laminated plywood.

- It will be easier to work if large sheets of material are dissolved into squares. You can choose an arbitrary size, for example, it can be with a side of 1 m.

- For the next step, you will need construction clamps. Sheets must be marked in pairs. Two must be bonded to each other. At a distance of 5 cm from the top and bottom edges with a gap of 20‒25 cm, 10 mm holes are drilled for fittings. They are fixed so that the holes coincide exactly with each other.

- In the case when plywood is not covered with laminate, then for a better lag from the mortar and protection from moisture, it is covered with a plastic film.

Filling walls with claydite-concrete

Filling walls with claydite-concrete

To prepare the solution, you will need:

- cement;

- expanded clay;

- water;

- plasticizer.

The ratio for these components in the order of their location will be - 0.7: 4: 0.45: 0.015. This means that for slightly less than 1 bucket (with a capacity of 10 l) of cement, 4 buckets of expanded clay, 5 liters of water and 150 ml of plasticizer are needed (ordinary liquid soap or shampoo can play its role). Kneading is best done in a concrete mixer - this will be the key to good mixing of the components.

Formwork

Formwork

If a base was erected, then the waterproofing should be laid in two places - on concrete and from above, on the base itself. In the case when the foundation was poured immediately to the desired height, then the ruberoid or bikrost is laid in two layers, and the seams are coated with bitumen mastic. The main difficulty will be in setting the first level. The sequence of works will be as follows:

-

Filling of expanded clay Filling should be started from the corners. This will not only ensure the evenness of the wall, but also facilitate the subsequent fixing of the formwork.

Filling of expanded clay Filling should be started from the corners. This will not only ensure the evenness of the wall, but also facilitate the subsequent fixing of the formwork. - Two sheets are fixed at an angle of 90 °. This can be done with metal corners on the side that remains outside. Here it is worth considering that the elements for fastening from the outside of the wall should be slightly longer than the internal ones so that they coincide on the ends.

- On the lining of granite, on top of waterproofing, fit several rods of reinforcement.

- Glass-armature or other tubular material is cut into segments whose size will be such as to enter the formwork plywood walls.

- Formwork sheets are installed. This will require studs whose diameter will be such that they fit inside the prepared tubes. The threaded element is threaded into the hole of the wooden sheet, then the nozzle is put on it and discharged through the second sheet of plywood. Fixing is carried out with the help of washers and nuts.

- The ends are closed with a flat board, the width of which will be equal to the width of the wall.

- Verifies the vertical and horizontal level.

- The prepared solution is poured into the cavity formed and well rammed.

- In this condition, it is left for a few days until solidified.

-

Monolithic wall After that, the formwork is dismantled.

Monolithic wall After that, the formwork is dismantled. - To fill the next level, several bars of reinforcement are laid again along the wall. Holes that remain from the previous fill will serve to fix the bottom of the formwork. All actions are repeated to the full pasture of the planned height.

- Lintels are filled with concrete. However, they must at least 15 cm on each side to go beyond the limit of the opening.

- Holes that remain from the time the formwork was installed can be repaired with foam.

With non-removable formwork

With non-removable formwork

There is also an option from non-removable formwork. To do this, lay in the half brick of two walls with a gap. Inside between them will be filled with expanded clay. The reinforcing element in this case will serve as a pin brick, which staggered inwards in a checkerboard pattern. The advantage of this solution will be a large thickness of the plane, as well as the absence of the need for external decoration, if the external row falls under the jointing.

See how you can make a removable formwork and fill in monolithic walls:

Block walls

Laying of claydite-concrete blocks

Laying of claydite-concrete blocks

The technology of laying claydite-concrete blocks is slightly different from the laying of ordinary brick. Here are just some of the nuances that must be observed:

- You need to start from the highest angle. It is determined using a water level or laser plane builder. Using the second tool is much faster and easier. A line is projected just above the foundation level. With the help of a tape measure, it is measured from it to each corner, where the distance is less - there is the highest point.

- The first block is set at the selected point. It must be maintained in all planes. From this reference element, all others are laid out.

- Between the two stones, on the outside, the fishing line or string is stretched. Its height should be the height of the row plus a layer of mortar. It is rearranged as necessary to a higher level.

- Verticality is maintained using a plumb or bubble level.

- The thickness of the seam must be 1 cm or less. This will reduce cold bridges, because the solution has poor thermal insulation.

- If you are doing this for the first time or do not have much experience, add a plasticizer to the masonry mix. It is intended to ensure that the solution does not sit down and harden longer. So there will be more time to fit each item.

- For greater reliability, a reinforcing mesh can be laid every few rows.

- Jumpers are made in the same way as in the previous version. For greater stability, the reinforcement is bent and tied with masonry.

The seam thickness should be small

The seam thickness should be small

Factory units can be with air cavities inside or without them. The base is better to lay out the second option - monolithic blocks. Also, their use is relevant if you plan to use concrete floor slabs. Additionally, they will need to make armopoyas. Wooden formwork is installed, crate is laid and concrete is poured. The minimum height is 20 cm.

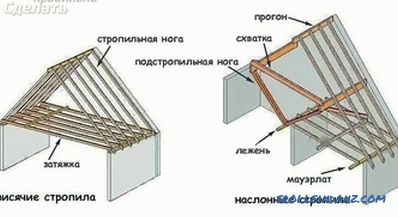

Roof

For a project of claydite-concrete, you can use both the metal structure of the roof system and the wooden one. The first has its undeniable advantages:

- fire resistance;

- longer service life;

- not susceptible to rotting and fungi;

- possibility installation in any weather;

- clear compliance of the parts declared in the project;

- minimum range of tools for installation;

- for a lightweight system there is no need for special lifting equipment.

Wooden truss system

Wooden truss system

The main disadvantage that can stop when choosing this design - low energy efficiency. The metal can freeze to low temperatures, which will contribute to the rapid cooling of the attic space.

Installation of rafters

Installation of rafters

For private houses it is better to use a triangular structure. Much will depend on what angle of the roof is specified in the drawings. It is selected taking into account precipitation and wind strength in a particular area. Also on the specific project will depend on the thickness of the materials used. Farms are made in the same way as wood. If the span width is up to 10 m, then jumpers are installed like crossbars. When the size exceeds the specified figure, then the installation of bracings that are directed downwards will be mandatory. Both sides must have the same number of racks for balance and proper load distribution. For this design it is better not to use hanging rafters, which are simply welded onto the mauerlat, it is absolutely necessary to provide a base. A channel of sufficient height and thickness of the metal acts as a mauerlat. In case of choosing such a solution, it will be necessary to take care of the quality insulation of both the attic space in general and the roof in particular. A good way would be to use stone wool. It is quite simple to lay in the gaps between the rafter legs. At the same time at the stage of construction it is necessary to consider the observance of this size.

Wooden structures are the most common. For the mauerlat, a timber with dimensions of 15 * 15 cm or 20 * 20 cm is usually used. Its mounting, as for the metal construction, is carried out to the studs, which are laid when casting the armored belt or using anchor dowels. In the second case, a punch is needed, with which holes will be drilled in the concrete. For basic elements, you can use a trim board 15 * 10 cm or 5 * 10 cm.

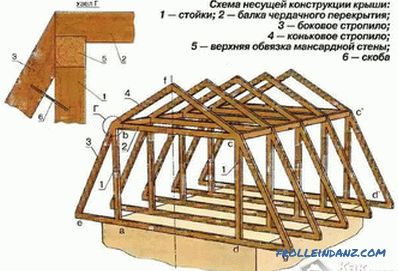

The truss system of the mansard roof

The truss system of the mansard roof

It is important to remember that installation begins with two extreme trusses that must be set in all planes and securely fixed. Connecting elements are mounted between them. These may be additional beams on pedestals that enter the sub-ridge space or strained threads that will allow them to withstand the level of other elements.

All spacers must be mounted in accordance with how you intend to use the attic space. If it is an attic, then they need to be shifted as much as possible to the edges in order to make more space. Another option would be to divide the whole territory into two rooms, then you can hide the racks in the alterations.

Internal and external decoration

Brick cladding

Brick cladding

In order to achieve maximum savings on heating costs, it is important to take care of additional weatherization. Run it in two ways. Each of them will depend on what type of exterior decoration is chosen. If you want to cover the walls with bark beetle, then you can use foam or foam plastics as an insulator. The sequence of actions will be as follows:

- The total area is calculated for all walls. To do this, you need to know the value for each separately (multiply the length by the height), and then add the results.

- In accordance with the obtained result, insulation is purchased. Its thickness can be 10 cm.

- It is attached to the wall with special plastic dowels with wide caps (umbrellas). In the case of expanded clay concrete, it is better to take care that their diameter is larger. This is due to the porous structure of the building material.

- The starting plate is attached to the base. In its quality can serve as a metal profile for plasterboard of sufficient width to go inside a sheet of insulation. The guide is set on the level and secured with dowels and screws.

- Polyfoam needs to be fixed, observing the vertical level in order to maintain a flat surface of the wall.

- The reinforcing mesh is fastened on top and tightened with special glue.

- After complete drying, finishing is carried out using decorative plaster.

Insulation and plaster

Insulation and plaster

In another case, you can use non-decorative plaster , and facing stone, which is placed on top of insulation. In this embodiment, the whole structure is more resistant to shocks.

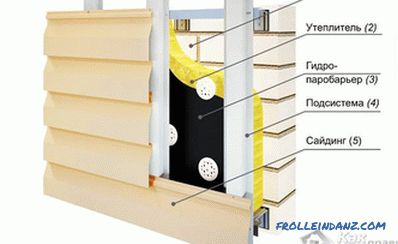

In the case where the veneer is planned using siding, the procedure will be as follows:

- As in the previous case, the amount of material required is calculated.

- The entire wall is covered with waterproofing.

- Mounted sheathing of metal profiles.

- Mineral wool is laid between the posts of the batten and fixed with umbrellas.

- The final step is to install the siding.

Siding installation scheme

Siding installation scheme

For more information on how to install siding, read here.

The porous structure of expanded clay concrete makes it easy to use ordinary plaster for interior decoration. This facilitates the task, in contrast to the finishing processing of cinder block. First of all, all walls are covered with primer or concrete contact. They allow not only to remove excess dust, but also to increase the degree of adhesion of materials. Next, the metal mesh is mounted, which will serve as a reinforcing component. After this begins the application of plaster. The final step is to install a drywall construction or putty.

As you have seen, such a project of a house can be implemented independently, starting from the drawing and manufacturing of building blocks. Do not neglect the advice of professionals and do not consider below his dignity several times to consult on the same issue. Good luck in your endeavors!

Video

An example of building a claydite concrete house:

About the advantages of clay blocks and features of their installation in the following video: