Nowadays, more and more often wooden lumber is used in the construction of the walls of houses, cottages, baths. This is due to the fact that the quality of the proposed material of large sections improves, and it becomes competitive with the log. During the construction of such structures it is important to ensure a reliable connection of the timber.

Profiled timber construction is easy to assemble, saving time and effort.

The construction technology of such houses differs little from the manufacture of a log log house. At the same time, stacking and processing is easier and easier, and in many areas the material is more accessible for purchase. One of the most important stages of construction is the connection of logs, on which the reliability of the whole structure largely depends.

The basic principles and provisions for laying timber

When docking, you must have the following tool:

Half-timber corner connection on the insert dowels.

- electric drill;

- Bulgarian;

- planer;

- hacksaw;

- chisel;

- hammer;

- emery sandpaper;

- ruler;

- caliper.

The docking operation during the construction of the wall is performed in two cases: the manufacture (bundle) of the corners of the house and the interlacing (buildup) of the timber in length. A particularly important process is docking in the corners. During its implementation, the reliability of the structure, its dimensions and the quality of the entire wall, as well as the design, are laid.

There are two types of corner joints: with or without a residue. Laying with the remainder is based on the fact that the end is in favor of the corner joint for a certain length. The main advantage of this type of work is a kind of wooden insulation of the corner of the house, which is especially noticeable in the wind. In addition, this design creates a certain design, which has its fans.

A plexus without residue implies that their ends are flush with the surface of the wall. The main advantage - reducing the size of the house and saving material during construction.

Connection of the beam with the remainder and without residue

Angular joints of the beam "root spike - groove".

The most common way to dock with the remainder is to connect using rectangular grooves, the so-called piling. This interlacing has three modifications. The easiest option is a one-way connection. In this embodiment, a rectangular groove is cut on one side. The dimensions of the groove on both joined bars must be the same. The width of the groove is equal to the width of the log, and the depth - half the height of its height. When joining the groove system to the groove (when the bars are perpendicular to each other), the lateral faces of the woven boards must be strictly in the same plane (the joint without projections). The distance from the end of the beam to the beginning of the groove determines the length of the remainder (departure).

The second option is a two-sided plexus. In this case, the groove is sawn on two opposite sides. The depth of the groove should be 1/4 of the height of the beam. With such a dock provides a more dense packing of the material.

Finally, a four-sided connection of a bar provides for the manufacture of a groove on all faces. The depth of the lower and upper grooves should be 1/4 of the height of the bar, the depth of the side grooves should be 1/4 of the width, and the width of all the slots should be 1/2 of its width. When using this method, the maximum density of the bars is achieved.

The most common ways to dock without a residue are: butt joining a bar, interlacing on keys and docking on indigenous spikes. Butt-packing is the simplest, but the most unreliable. In this case, the end face of one bar rests against the side face of the other (in the next layer they change places). Joint Fixed with nails or metal straps. With this arrangement it is very difficult to control the pressure of the end face, which depends on the quality of its processing, and to ensure the perpendicularity of the elements in the node. This method is best used only in the construction of light garden buildings (shed, etc.).

A slightly safer half-tree method, which implies the overlapping of the bars on each other, while at their ends is made a cut with a length equal to the width of the material and a height equal to half the height. Thus, the ends of the bars are sunk into each other. The docking place is hardened with nails.

Connection on radical spikes

Angular joint diagram of the dovetail beam.

This method is based on the formation of spikes and their corresponding nests directly on the ends. At the end of one of the joined elements, a spike is cut in the middle of the butt. The length of the spike is equal to the width of the bar, and the width is 1/3 of the height. Accordingly, a groove with a width equal to the width of the spike is made on the second bar. When docking the spike is tightly pushed into the groove. To insulate the corner of the house, as a rule, a flaxed canvas is laid in the groove before the grouping.

One type of such a connection is dovetail docking. In this case, the spike is made of a trapezoidal shape, widened side out. The groove is made of a similar shape. This joint is more dense and reliable.

Connection on a non-root spike

A non-root spike, unlike the root spike (which is formed in the center), runs from the edge and is vertical. When docked, such a spike should be on the inside of the wall. On the side surface of the second bar is made the corresponding transverse groove. The spike can be of two types: a width equal to 1/3 of the width of the timber, or a width equal to half the width. The length of the spike is equal to half the width of the material. Docking is a butt joint with a spike.

Connection with the key

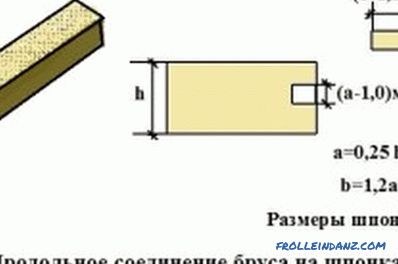

Longitudinal connection of the bar to each other in length using the keys.

Often the method is used, which is a combination of butt and spike joints. In this case, a slot is made at the end of one of the bars. A similar groove is made on the side of the second beam in the transverse direction. The beams abut each other, as when the butt is interlaced, but a wooden key is inserted into the grooves for the entire length of the grooves. The key in cross section is a square with a side of 1/3 the width of the base material. The key is inserted so that one half of it is in one bar and the other in the other. You can install a key both vertically and horizontally, but most often the first option is used as a simpler to manufacture.

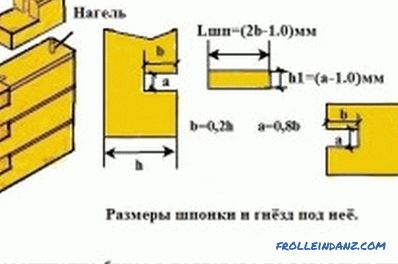

Laying with dowel

The layout of the dowels in the bar.

To strengthen the joint in the corner of the house, additional reinforcement is used with pins, which are called Nogle. They are installed inside the bars and do not allow deformations to occur during the drying of the material; they take on mechanical stress. A metal pipe or fittings can be used as a dowel. You can make a nog of wood.

Most often, bracing hardening is used in a joint on a root spike. In such a docking hole is drilled, with a diameter of 2-3 mm larger than the diameter of the dowel, in the vertical direction. The pin is inserted into the hole. The diameter of the dowel is selected in the range of 25-50 mm. The length is determined from the condition that the nog should connect two rows.

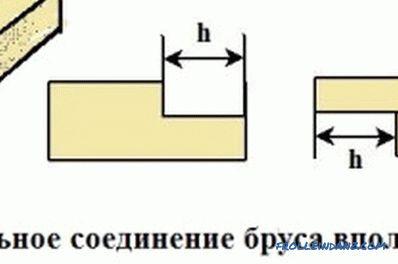

Longitudinal docking

Connection diagram for half-timber.

During construction, there is often a need to increase the length, for which various methods of longitudinal connection are used. Basically they use the method of docking in the "half-tree" and the combination of the beam with the longitudinal root spike, as well as the connection with an oblique lock. The first two methods do not differ from similar methods in the manufacture of corners. The only difference is that the beams themselves are arranged in series.

A simple and fairly reliable method of connection is a longitudinal connection in "half-tree" using a nog.

In this case, the process is very convenient. The joints of the two bars are placed horizontally and 2-3 holes are drilled with a drill. Wooden round pins with a diameter of 15-20 mm are inserted into the hole. The docking place can be treated with glue. It is possible to use a wooden dowel with subsequent sizing when using a joint with a root spike.

The connection with an oblique lock is quite difficult to perform. A bevel is made at the end, and a spike forms on the bevel surface of one beam, and a groove is formed on the bevel of the second.

Creating a warm corner

When joining the bars of the wall of a residential building, care should be taken to warm the joint areas. In the joints due to loose joints, inaccuracies in the grooves may decrease thermal protection. To prevent this, it is recommended to use the so-called warm corner. To do this, between the joints in the beams placed heat insulator type tow or flax fiber. This must be done during the installation of the corner knot.

There are many ways to dock how to join timber when building it, to make the corners of the walls of a timber. Proper installation with such joints is an important factor determining the quality of work. What method to apply, it is necessary to solve taking into account real conditions and a type of construction.

Didn't find the answer in the article? More information on the topic:

-

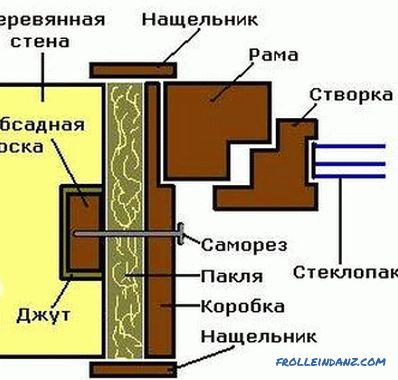

Wooden windows: DIY-making

Do-it-yourself wooden windows: the advantages of installing wooden structures. Varieties of windows from natural breeds. The stages of the manufacture of wooden windows, installation design.