Heating in the house is an integral engineering network. Of all the possible underfloor heating systems, warm water heating is most in demand, and this despite the complexity of its installation. Thanks to the warm floor in the room you can create a comfortable and cozy atmosphere. In this article we will consider the general recommendations for the installation of a warm water floor.

How it works

A heated water floor when assembled is a layered structure also known as a “heating cake”. Its thickness depends on several factors:

- The thickness of the insulation used.

- Thickness of the roughing and finishing leveling screed.

- Diameter of the heating circuit.

A floor heating device includes a boiler, submix assembly, a manifold, heating circuits, and other accessories.

Types

There are 3 types of floor heating systems:

- Concrete . Heating contours are filled with concrete screed, which in addition to the protective and leveling function performs the role of heat accumulation.

- Nastilnaya . Mostly this system is implemented in wooden houses on logs. These are all cases in which it is impossible to build a concrete screed or the total weight of the screed will not withstand the overlap. Also, this technique is used in panel houses, where floor slabs are unable to withstand heavy loads.

- Wooden . A similar system is used in the same place as the tabletop, with only one difference: heating circuits are mounted between the lags under the flooring, which is laid on top of the lag.

The flooring and wooden heating systems can be basic only in the case when the room and the whole house are well insulated. That is, the total heat loss should not exceed 40 W / m 2 . Otherwise, when the heating is turned off, the room will cool down very quickly. In the case of a concrete screed, the situation is different; the screed itself is the heat accumulator, so for a while a comfortable temperature will be maintained in the room. Thus, a flooring or wooden system with poor insulation can only serve as additional heating to the main radiator system.

Heat floor cake

A pie means all layers that make up the floor heating design. Depending on the selected system, its composition may vary slightly.

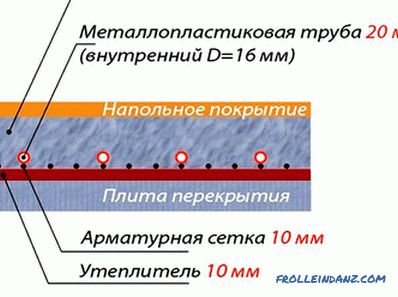

Cake of a concrete system

The thickness of the cake of a warm concrete floor can vary. Below is a diagram of the cake with the approximate dimensions of the thickness of each layer:

Floor cake, in which each layer has its own purpose

Floor cake, in which each layer has its own purpose

Consider the sequence of laying the cake for the heating of the concrete system:

- Draft foundation . The screed is poured over a slab or primer. In the latter case, sand and crushed stone with a total thickness of up to 60 mm on average must be poured and rammed.

- Waterproofing . Required if groundwater is located nearby.

- Heat insulator . Its main task is to eliminate the bridge of cold and heat leakage. For example, you can use polystyrene foam with a thickness of 20-115 mm and a density of 30-40 kg / m 3 . Especially the thickness of the insulation should be large if there is an unheated basement or ground under the floor. If it is decided to use special mats (made of insulation) with lugs, then it is important to consider that their thickness is 30 mm. To give the insulation layer the required thickness, in addition, polystyrene foam is laid under the mats.

- Polyethylene film . Placed in two layers. Film thickness not less than 150 microns.

- Reinforcement mesh . It is necessary for imparting a high-strength screed in cases where its thickness exceeds 60 mm and a high load on the base is expected. For example, the diameter of the grid bars can be from 3 to 5 mm, and the cell size is 100 * 100 or 150 * 150 mm.

- Pipe . The pipe spacing is 100-300 mm. The pipe is fixed to the reinforcing mesh with special plastic clamps. Where the expansion joint will be arranged, a corrugation is put on the pipes.

- Finish concrete screed .

- Substrate. Under laminate, parquet or other facing material.

- Facing.

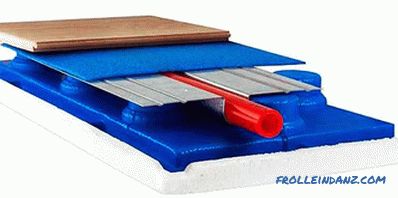

Pie of the flooring system

The peculiarity of this method is that after the installation is completed, the floor heating system is immediately ready for operation.

The basis is a mat with bosses and an aluminum guide

The basis is a mat with bosses and an aluminum guide

The cake of the flattening system consists of the following components:

- Draft floor .

- Mats with bosses . They are without insulation. In this case, the heat insulator is purchased additionally. The total thickness can be from 30 to 70 mm. Existing lugs allow secure fixing of pipes.

- Pipe . Its installation is carried out in a special aluminum plate.It is important to note that not every pipe is suitable for a floor heating system. It should have a special coating that prevents squeaking.

- GVL or other flattened material .

- Substrate .

- Facing layer.

It is worth mentioning separately the layer that lies between the pipes and the facing material. The type of substrate may vary, depending on the method of finishing. If it is planned to lay ceramic tile or linoleum on the floor, then a moisture resistant plasterboard slab is put in two layers on top of the pipe. However, after a while, drywall under the tile can crumble, so alternative substrates can be considered: moisture resistant plywood, glass-magnesium sheets or chipboard.

Cake of a wooden system

Consider 6 ways of laying a warm floor on wooden logs that are implemented without a screed:

1st method .

Boards of 50 * 150 mm with a step of 600 mm are laid on the wooden floor. Mineral wool 100 mm thick is laid between the lags. From above unwinding heating pipes. Holes are made in the corresponding places in the logs for the passage of the pipe. From above the lag is laid plywood and finishing material. The disadvantage of this technique is that an airbag is formed between the plywood and the pipe. This has a negative effect on thermal conductivity.

2nd method.

Between the installed lags, a heat-insulating layer of polystyrene foam, mineral wool, etc., creeps. The chipboard, OSB or plywood is mounted on top. After the plates are cut from chipboard with rounded corners. They will later form the heating circuit. The resulting plates are screwed to an existing base with a pitch greater than the diameter of the pipe by 4 mm. Next, put the foil as a reflective layer. Top mounted heating pipe. Finally, the surface is covered with laminate. This method is not suitable for flooring, as the base is quite mobile.

3rd method.

This method is quite laborious. Between the lags also fit the insulator. After the board is taken equal to the pitch of the pipes. In one corner a groove is made along the entire board for laying the pipe. At first, the foil is laid in it, and then the pipe. Then mounted facing material.

4th method.

In this case, special aluminum plates are used with grooves for pipe laying. They are attached to the logs. But in this case, it is recommended to lay a thick material on top of the plates, for example, chipboard to prevent bursting. And only after that put the finish.

Aluminum plates are laid on the wooden floor, which are guides for the heating circuit

Aluminum plates are laid on the wooden floor, which are guides for the heating circuit

Cake wooden system warm water floor. The pipes are laid with a certain pitch

Cake wooden system warm water floor. The pipes are laid with a certain pitch

5th method.

A raised floor is mounted between the lags. Between the beams laid out the insulating layer. On top of the sheets are placed with the bosses in one level with the top of the lag. At the intersection of the lag with a pipe, small grooves are made, and a special corrugation is put on the pipe. This is important because, due to linear expansion, the pipe may rub against wood. The substrate and finishing material are laid on top.

6th method.

This method is one of the simplest. The pipes are laid directly into the insulation, namely polystyrene. The space between the top of the lag and the pipe can be filled with plaster, which will act as a heat accumulator. However, you can fall asleep and clean dry sand.

Video: making a wooden cake

Where you can install

The underfloor heating system can be installed in different rooms. However, in each case it is important to consider some features.

- In the apartment . In city apartments where a centralized heating system is used, it is prohibited to install a heated water floor . Modern new buildings already have separate risers and outlets in each apartment for the implementation of such heating. On the other hand, some at their own risk introduce a similar system in their apartments. To do this, even developed a number of schemes, through which the connection to the central heating system. However, this causes a number of difficulties. Significantly increases the level of the floor. This can be a problem in apartments with low ceilings. In addition, there is a risk of flooding the neighbors. Therefore, all materials used must be reliable and of high quality. If the house has a panel overlap, then it may not withstand the additional load, so many resort to alternative heating - electric. Connection from the central system requires a significantly lower coolant temperature. In the heating system, on average, the coolant has a temperature of + 60 ° C. For floor heating it is too much, as usually + 30 ° С is enough.If you want to get official permission to install, then you should contact the utilities and solve issues on a personal level.

- In a private house . As for private houses, the situation is much simpler. It is easiest to install at the stage of building a house, or rather, before pouring the screed. An important requirement is the arrangement of high-quality hydro and thermal insulation. Also, the heating cake should include a special reflective material. If you do not meet these requirements, then there will be significant heat loss. In a private house a mixing unit is being built, an additional circulation pump is installed, which will evenly distribute thermal energy over the entire floor. However, with all the merits, it is important to take into account the disadvantages of such a decision. After the floor heating has been fabricated and the finishing screed is poured in, heating cannot be put into operation for an average of 4 weeks. Although plasticizers are added to the screed to dry quickly, it still needs to dry naturally. This minus is insignificant and temporary.

Two contours of a water heated floor in a private house. Everything is ready for pouring the screed

Two contours of a water heated floor in a private house. Everything is ready for pouring the screed

- In the garage . Engage in the arrangement of the garage should be at the stage of its construction. In the ready-made garage to perform these works will be problematic and at the same time expensive. The main condition for the floor in the garage - the ability to withstand high loads. The average weight of a passenger car is 3.5 tons. Given this, the coupler must be made of durable concrete. Moreover, after pouring the concrete screed, it is impossible to turn on the heating. If suddenly the heating system fails, it will be problematic to fix the problem, in the worst case, the entire floor in the garage will have to be completely dismantled. After repairing the leak, re-install the floor covering.

- Bathroom . Bathroom is a place of constant accumulation of moisture. For this reason, the presence of such heating would be an excellent solution to prevent the formation of dampness, mold and mildew. To arrange heating it is required to raise the floor level by an average of 110-130 mm.

Calculation

First of all, you should decide whether the floor heating will be basic or additional to radiator heating. It is important to consider the nature of the floor. Ceramic tile has a high thermal conductivity. As for the tree, this figure is much lower. Therefore, the type of heating system will depend on the type of coating.

In addition, the area and configuration of the heated room is taken into account. One heating circuit should not exceed 120 meters. After that, possible heat losses are determined, which are calculated on the basis of the following:

- of what material the house is built (blocks, wood, brick, etc.).

- glazing type (double-glazed windows or profiles are used).

- The average temperature in your area.

- are there any additional sources of heat.

Next, decide what level of temperature you want for each individual room. Here you can build on the following indicators:

| Room | Maximum surface temperature floor |

| Living rooms | 29 ° С |

| Near external walls | 35 ° C |

| Bathroom, pool, etc. p. | 33 ° С |

| Parquet floor | 27 ° С |

Video: calculating the floor heating

Video: calculating the temperature of the floor heating

Design

The key element of the floor heating system is pipes. The length of the contour is directly dependent on the diameter of the pipe. The following data is known:

- Pipe Ø16 mm - up to 90 m.

- Pipe Ø17 mm - up to 100 m.

- Pipe Ø20 mm - up to 120 mm.

The larger the pipe diameter, the smaller the hydraulic resistance in it. If the room has a small area, then usually one circuit is enough. However, if with a pipe diameter of 20 mm, the entire area of one room lacks 120 m, then it is better not to add length, but to make 2 contours. It is better that their length be the same with a difference of up to 10 m.

An important role is played by the pipe layout, which can be 15, 20, 25 and 30 cm. If we are talking about large rooms, such as gym, then the step can be in the range of 35, 40 or 45 cm. However, it is recommended to take a 10 cm pipe pitch near large windows.

Consider separate zones in the table:

| Zones | Stacking step |

| Near the outer wall and large windows | 10-15 cm (6 rows ) |

| The middle of the room | 20-30 cm |

| Bathroom, shower, bathroom | 15 cm |

These are recommended numbers. The choice of a step also depends on the pipe used. If it is metal-based laminate, then it is extremely difficult to bend it without damage a step with a small radius. Therefore, if the laying pattern is a snake, then the ideal pitch is 15-20 cm.

If the area of the heated room is from 50 m 2 and more, then the recommended pipe diameter is 16 mm. Even under the condition of a well-insulated house, it is recommended that the pipe spacing should not exceed 15 cm with the Ø16 mm pipe. The thicker the pipe, the higher the costs you expect. This is especially reflected in the purchase of fittings and other materials of larger diameter. The project should be made with a pipe Ø16 mm.

In some cases, used pipes Ø20 mm. However, such costs are often unjustified. After all, the volume of water in the system increases significantly, which will require more thermal energy to heat. Plus, it is difficult to bend such a diameter.

When designing, it is important to consider the following nuances:

- First, install partitions, and then determine the number of contours. In the same room should be one circuit.

- The collector should be in the middle of the house. If this is not possible, the problem of the difference in the length of the contours is solved by installing flow meters. Due to this, the coolant flow will be uniform.

- If you need to install two manifolds, then each must have a separate pump.

- The overlap between the first and second floor is necessarily insulated. This is necessary not to warm the overlap itself.

The process of designing a heated floor is complex and responsible. Therefore, many use the services of specialists or special programs.

Laying heating circuits

There are several pipe laying patterns:

- Snake.

- Snail.

- Combined.

Each of them has its own technical features, which we consider further:

- Snake . This scheme has several obvious disadvantages. When entering the room temperature of the heat carrier and the floor is high. The farther, the colder the floor. This is explained by the fact that the cooled coolant returns through the return line. When installing such a scheme requires special skills. If metal-based laminate is used, the laying step is often done 20 cm or more, since it is difficult to bend the pipe at a smaller angle. However, the pitch can be reduced to 10 cm, but small rings should be made around the edges, which is a laborious process. Often, such a laying pattern is used when it is necessary to align adjacent contour zones. Also, this method of laying pipes is acceptable if the area of the room is very small, up to 6 m 2 .

- Snail . Its principle is that first of all the contour is laid around the perimeter of the room with a gradual narrowing towards the center. Back contour returns to the starting point. In this case, if you have planned a step between a pipe of 20 cm, then the contour is first put in steps of 40 cm. On the return stroke, the pipe is laid between the already laid and thus forms a step of 20 cm. This laying pattern is one of the effective ones. This is explained by the uniform distribution of thermal energy over the entire area of the room. Moreover, it is possible to strengthen the zones near the outer wall or large windows by reducing the stride distance. For such a scheme there are practically no restrictions on the shape and size of the premises.

- Combined . This implies a combination of the above two pipe-laying systems. For example, one part of the room can be lined with a snake, and the other - a snail. There is also the practice of combining water floor heating with electric. However, in this case, electric heating will serve as an extra. This is especially effective in the period of early autumn and late spring, when it is not reasonable to turn on water heating.

Video: Layout of the hinges of the heating circuit

Insulation

Insulation for the floor must be of high quality and safe for others during operation. The selected heat insulator must meet the following requirements:

- Fire resistance.

- Low thermal conductivity.

- Moisture resistance.

- Strength.

Therefore, choosing a heater, it is important to consider its technical characteristics. Below are several types of insulation that are successfully used in the heating cake.

Expanded polystyrene

If you have a concrete screed, then expanded polystyrene is ideal. It is of two types:

- Smooth.

- With bosses.

Styrofoam to create a thermal insulation layer

Styrofoam to create a thermal insulation layer

The second option greatly simplifies and speeds up the process of laying pipes . Also expanded polystyrene is divided into 2 types:

- Conventional foam.

- Extruded polystyrene foam.

If we compare the thermal properties, then they are higher in extruded polystyrene foam.

Cork

This material is a suitable option in all respects. Among its positive properties, you can highlight:

- With sudden temperature changes, the plug does not change in volume.

- Eco-friendly.

- Under the weight of a concrete screed almost does not deform.

- Although the material has a small thickness, it is characterized by high-quality thermal insulation.

However, the obvious disadvantage of this heater is price. Its cost is 3 times higher than other materials.

Penofol

Penofol or polyethylene foam is often used when installing a heated floor. It is presented in the form of a rolled foil material with a thickness of 3 to 10 mm. For the convenience of laying pipes, marking is applied to the foiled surface. If you live on the ground floor and beneath you ground or unheated basement, then this insulation will not be enough. It must be combined with polystyrene foam.

It is better to choose penofol with a metallized surface, but not aluminum. This coating does not interact with the negative medium of the liquid solution, which is able to corrode the usual foil.

Mineral wool and ecowool

The density of the insulation used is recommended to be at least 80 kg / m 3 . Mostly used for laying wooden systems. In this case, the insulation is placed between the logs or wooden beams.

Collector

There are several types of collectors that are used for installation work:

- Collector with outlets for Eurocones. One of the simplest types of collector. It is a pipe having internal and external threads for connecting heating circuits. However, to introduce it into the floor heating system will have to buy a large number of parts for a complete set.

- Manifold with outlets for connecting circuits and valves for adjustment. Often these are Chinese collectors that are sold in stores. They have one obvious disadvantage - after a while, water may flow from under the arms. This is due to the low quality of the coolant. They are amenable to repair, it is enough to replace the rubber gasket. Such collectors are not intended to be equipped with additional control automatics. They will be ideal for homes with a small area where the contours are the same length.

- There is also a collector for connecting metal-plastic pipes. It has adjustment valves and fittings. Such valves can be equipped with a servo, whose work will be regulated by a thermostat installed in the room. The fittings themselves are also known as eurocones, which consist of 3 parts: an eurocone, a compression ring and a cap nut. Also eurocone has a sealing ring.

- In those cases when the length of the circuits is different and manual adjustment is not possible, it is recommended to purchase a collector with flow meters and sockets for servo drives. On some collectors they hide behind blue hats. Due to this, it is possible to regulate the temperature of the coolant in each individual circuit. However, you can combine - buy a collector for flow with flow meters, and the return pipe - with conventional valves for manual adjustment.

A collector for a warm water floor, the main nodes are marked

A collector for a warm water floor, the main nodes are marked

As for the mixing unit, then it must contain:

- Safety valve. It signals the mixing of the coolant at a very high temperature.

- Circulation pump. Thanks to this device, the system heats the room evenly.

- Bypass. Prevents overloading.

- Discharge valves and air valves.

Particular attention should be paid to a special valve, which can be two-way and three-way. Each of them has its own differences and purposes of use.

Two-way valve . In his kit, he has a thermal head with a moisture sensor. If necessary, the supply of hot water is blocked. As a result, water is automatically mixed. Mostly such valves are introduced into the heating system, where the area of the residential zone does not exceed 200 m 2 .

Three-way valve . Such a valve defines two indicators at once: balancing of the bypass valve and characteristics of the check valve. It mixes hot and cooled coolant. Often, three-way valves are equipped with a servo controlled thermostatic and weather controllers.The mixing process is carried out due to the presence inside the valve of a special valve that regulates the flow of fluid. The similar valve is used in systems of a heat-insulated floor with a large number of contours.

Also the collector and mixing unit are equipped with outdoor temperature sensors. They allow you to adjust the temperature of the coolant, starting from the temperature of the street. Although such adjustment can be done independently, the presence of such sensors allows you to adjust the optimum temperature.

Installation of a heated floor

The installation process consists of several successive stages. Acquaintance and observance of technology will allow you to independently perform all installation work.

Waterproofing and installation of damping tape

First of all, preparatory work is carried out. To do this, completely removed the old screed. If the differential in the room is more than 10 mm horizontally, then it should be leveled. To do this, you can fill the draft self-leveling screed with a thin layer.

Mandatory installation of a damper tape around the perimeter of the room

Mandatory installation of a damper tape around the perimeter of the room

Next, it is important to protect the insulating layer from condensate. To this end, polyethylene is placed on the roughing screed. Docking is overlapped by 10-15 cm. The joint is necessarily glued with tape.

The next stage of preparation is the installation of a damper tape. It is necessary to compensate for the linear expansion of the screed when it is heated. If it is not used, then after a short time, the screed may crack. The damper tape is fixed along the perimeter of the entire room to the wall with the help of a self-adhesive layer or adhesive tape.

Laying insulation

The next step is the installation of insulation. The choice of insulation and the method of its installation depends on the type of room and the purpose of using heating. If you have the first floor and there is no heated basement, then the insulation should be impressive. A layer of expanded clay is poured and expanded polystyrene with a thickness of up to 100 mm is used.

As for the method of laying insulation, then using a cork or penofol is quite simple. These are sheet materials that are glued together with tape. If polystyrene systems with grooves are used, their assembly is also not associated with particular difficulties. Between themselves, the insulation is joined with the help of special slots.

However, it is not always possible to use such heaters. Often the most affordable - foam. In this case, its installation should be carried out butt joint. Between themselves, it is desirable to glue, for example, with foam. Upon completion of the insulation the entire area should be covered with insulation.

Consider the sequence of floor insulation using polystyrene:

- Step 1 . The first sheet is placed in the corner of the room so that both sides are tight to the corners of the walls.

- Step 2 . Further the sheet is put end to end, tightly fitted one to one.

- Step 3 . If it is necessary to bypass a corner, a column or another obstacle, then polystyrene is easily cut with a sharp knife.

- Step 4 . The next row must be laid with a small offset, exactly half the sheet.

If you have planned the insulation in two layers, then the second layer of insulation should be laid across with respect to the first. Due to this, the joints will not coincide with each other. At the end of a special film is put with markup for mounting pipes.

If the heating is installed on a wooden floor, then mineral wool is used as a heater. It is placed between the lags. When installing, the width of the mats should be slightly wider than the distance between the lags. This will allow to lay insulation tightly and prevent the appearance of cold bridges.

Video: preparation of the base, laying of insulation and reinforcing mesh

Pipe installation

When the insulation is done, it is time to install the heating circuit. In this process, it is important to accurately calculate the laying step, the length of the contour and the number of outlets at the collector. However, before this is to discuss the choice of heating pipe.

How to choose a pipe

There are several types of pipes used for a warm water floor, each of them is in a different price category. The cost of a pipe depends on the manufacturer.

| Pipe | Features | Approximate / average price per meter |

| | Connect pipes with special fittings, forming a strong and tight connection. However, it is easy to damage them during installation. Maintain water temperature up to 120 ° C. They are sold in coils, which greatly simplifies the process of installation and delivery. | 80 p. |

| | When heated, the metalplastic tube is not deformed.The pipe is flexible and retains its shape after bending. Low weight simplifies installation work. | 500 p. |

| | These are expensive pipes that are rarely used. They have the lowest level of bending radius. The service life is 50 years. Operating pressure from 400 atm. | 500 p. |

Pipe laying

At the pipe laying stage, you cannot do without an assistant. The pipe on the warm floor is sold in coils, so one will unwind, and the other will hold the bay. Laying method depends on the chosen system. If the choice fell on special mats with bosses, then the work is greatly simplified, the main thing is to observe the laying step. If a film with markings is laid on top of the insulation, then special clips are used to fasten the pipe. What if there is no such markup? You can do it yourself. To do this, use a chopping cord with paint.

When installing the pipes it is unacceptable that they are interrupted. One circuit should consist of one whole piece of pipe. Begin laying with the farthest areas. It is very convenient when the insulation is made in two layers. In the first layer of insulation you can put the transit pipes and the necessary engineering communications.

The pipe installation process consists of several stages:

Stage 1 - unwind 10-15 m from the coil. Put one fitting on one end and connect its to the installed collector.

Stage 2 - the pipe at the collector is connected to the flow.

Stage 3 - by marking the pipe is fixed to the heater with harpoon-clips. If the section is straight, then an interval of 40 cm is sufficient. When cornering, the interval is reduced to 15 cm. When bending, be extremely careful not to twist the pipe.

Stage 4 - during installation, make sure that the pipe is not under stress. She should be free. Otherwise, the voltage will constantly pull out the brackets.

Stage 5 - if the bracket has flown, retreat from the previous place by 5-10 cm and re-fix the pipe.

Stage 6 - when you have rounded the entire circuit, the pipe is fed back to the collector and connected to the return pipe using a fitting.

For proper balancing, it is important to have information on the length of each contour. Marks can be made on the collector itself, for example, assign a number or name of the room to which it is going to each contour. Relevant notes can be made on a piece of paper. Don't keep everything in your head. The pipe section near the collector should be insulated, otherwise there will be a strong overheating of the floor. Moreover, it is recommended to insulate the pipe through one, i.e., the insulation is put on the supply and the return pipe is left untouched. Thus, the return line will not heat up from the flow.

There are several methods of fastening pipes:

1 method : tightening clamps.

2 method : mild steel wire.

3 method : special stapler and latches.

4 method : locking track.

5 method : mats with bosses.

6 method : distribution plate made of aluminum.

Video: laying of a heat-insulated floor

Reinforcement

Often, the first layer of reinforcement is placed on top of the insulation. In this case, the fastening will be carried out with the help of nylon puffs. Separate parts of the mesh are tied together by knitting wire. The mesh size of the reinforcement mesh depends on the step you select. The mesh should have Ø5 mm. In addition, a reinforcement layer is also laid on top of the pipes. This is explained by the fact that the grid lying below will not have any effect.

Crimping

Crimping refers to a process that allows you to make sure that all wiring connections are air tight and that the pipes are free from defects. This process is performed immediately before pouring the screed.

Pressure testing can be done in two ways:

- Water.

- By air.

Pressure testing with water

All circuits must be completely unwound and connected to the manifold. The system is filled through the power supply, it creates pressure up to 2.8 atm. at least 2 atm. In this case, the coolant must first be down to the mixing unit.

Next, the process is as follows:

- All caps on the return pipe are closed, often they are blue.

- After the in-feed valve opens.

- In the process of filling pipes with water, there can be a hissing sound, this is air coming out through a Mayevsky valve or an automatic air vent.

- Now the valve on the return line opens. So, it will be possible to bleed air through the drain valve on the return manifold.

- The filled circuit closes on the return line and the next one opens here.

- Finally, the valve in front of the supply manifold closes and the valve in front of the return collector opens.

Having filled the system with water and bleeding, you need to inspect the structure for leak detection.

Pressure testing with air

Pressure testing of the heating system with a compressor with air

Pressure testing of the heating system with a compressor with air

At the time The process of pressing the heated floor with air is automatically removed by an automatic air vent and in its place a cap is twisted. To work, you will need a compressor or automobile pump with a pressure gauge. Pressure at pressure testing with air should be three times more than the worker. Therefore, create air pressure up to 5 atm.

Similar pressure should be created only in the floor heating system, and not in the highway connecting the boiler and the collector. This is explained by the fact that some boilers are designed only for pressures up to 3 atm. Therefore, this area is checked later separately.

So, when air is pumped into the system up to 4 atm. , leave the taps closed for a day. Pressure should not fall. Although the minimum deviation will be, as when pumping the compressor will slightly heat the air, which will cool down later. To make sure of tightness, you can walk through all the joints with soapy water.

Screed

When it comes to finishing screed, it is important to provide some important conventions:

- Water cannot be drained from the system, but kept at a predetermined pressure 1, 5 atm.

- Turn on the heating is prohibited.

- Make temperature joints.

The temperature joint will completely eliminate the possibility of cracking of the screed. As the temperature of the seam is used damper tape. The area of the room can be divided by 20 m 2 (this is necessary if the area of one room significantly exceeds this figure). Pipe, in the area where it passes through the temperature of the seam, be sure to strengthen the corrugation.

To fill the screed, it is recommended to use special additives that will improve the technical characteristics of the screed. In addition, a plasticizer is added to the concrete, which prevents the tie from cracking when it is cooled / heated.

Concrete composition:

- Concrete and screenings - 1: 6.

- Concrete, sand and rubble - 1: 4: 3.5.

The plasticizer and other additives are poured during the mixing of the concrete mix. The proportion is determined on the basis of the manufacturer’s instructions on the label.

Filling of the screed at beacons is aligned with the rule

Filling of the screed at beacons is aligned with the rule

For living quarters, just enough thickness of the screed 50 mm, for factory premises up to 100 mm. It is important to consider the following property of the screed - heat accumulation. The thinner the screed, the less time it will retain heat. If it is too thick, it will take more heat to warm it up. Therefore, the optimal thickness of the screed is 70-80 mm.

Before pouring, make sure that the floor heating system has a pressure of 1.5-2 atm. It is forbidden to turn on the heating in the process of hardening of concrete.

The process of manufacturing a tie for beacons is as follows:

- The level of metal beacons are set.

- Beacons are not installed on pipes. You can lay out a thick solution in the form of mounds, on which beacons are installed.

- Concrete is smoothed by the rule. It is important to make sure that the air bubbles are completely out of the body of the screed.

- The next day, when the concrete had not yet seized, it is necessary to remove the beacons, clean these places and fill them with mortar.

Video: screed filling

Commissioning

The working temperature should be entered gradually. First, set the temperature to 25 ° C. After each day, raise it to 5 ° C. If antifreeze is used as a heat carrier, then an increase is carried out at 5 ° С, and if water, then immediately at 10 ° С. This is an important requirement, since it is possible to avoid sudden and uneven overheating, as a result of which the screed cracks.

So, commissioning is carried out as follows:

- Ensure that all taps on the manifold are open and the coolant is circulating through all circuits.

- The thermal head of the mixing valve is set to the minimum temperature value.

- The circulation pump is turned on when the boiler is turned off, as the pump on the boiler will interfere.

- From time to time it will be necessary to bleed off the accumulated air.

- With flowmeters, check the circulation of coolant through all circuits.

- Next you can turn on the heating.

Video: filling the system

Prices for water-heated floor

The cost of work, depending on your place of residence, may vary slightly. On average, prices are true.You can see the prices in the table below:

| Name | Average cost per m 2 |

| Installation of a heated floor without preparatory and concrete work | 400 p. |

| Installation of the collector | 1000-2500 r. |

| The hidden location of the collector cabinet | 2000 p. |

| Draft screed | 60 p. |

| Installation of the damping tape | 60 p. |

| Waterproofing installation | 60 p. |

| Pressure testing of the system | 20 p. |

| Laying the mounting grid | 150 p. |