The box is a necessary thing in everyday life. It makes no sense to buy or order it, because it is much easier to make a thing with your own hands from boards. The main thing - step by step to comply with the technology, to choose the right board and know how to make a box. Then everything will work out.

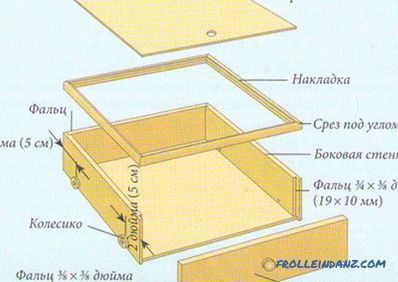

Scheme of plywood box.

Choice of the board and manufacture of parts

The size of the boards depends largely on the size of the intended product. There is a widespread belief that low-quality boards are suitable for a box. Is it so? If the surface of the tree is heterogeneous, with knots and deformations, then a person can get injured when sawing or processing the board. In order to create such a construction, it makes no sense to take high-quality expensive wood. It is best to choose a board of medium size and quality. How to make the simplest box where you can put the tools?

To make this design you will need:

- boards;

- self-tapping screws;

- sanding pads ;

- joiner's pencil;

- ruler or triangle;

- electric jigsaw or circular saw.

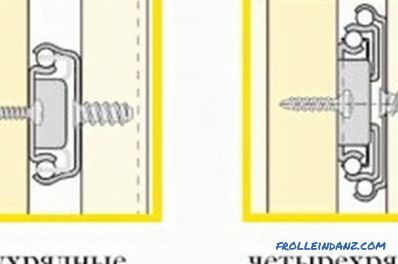

Types of ball guides for the box.

The best for this board fit a width of 22 mm. Self-tapping screws will be required for fastening, and grinding sandpaper for grinding the boards and the surface of the finished product. It all starts with markup, for which you need a carpenter's pencil and an ordinary ruler. It is best to take a triangle ruler, because with its help it is more convenient to mark the boards from which to make the box.

Practically do not use hand tools for cutting wood. To make the box, you need a circular saw or jigsaw. Be sure to pay attention to the teeth of the electric saw. They should be small and even. Such designs for domestic use are not made of thick wood. Powerful saw, which is usually used for cutting trees and landscaping, is not needed here. There is another nuance: starting from sawing off the boards, first make a test cut on the wood to see how it will be sawn, and only then proceed to the main operations. In order not to be mistaken with the dimensions of the finished structure, for this purpose it is best to prepare a “pattern” in advance: make its bottom and walls out of paper. This is very convenient, because then it is enough to attach the "pattern" to the wood and transfer the necessary parameters to the boards.

Once all the wooden parts are cut, they are sanded. Then 3 holes are drilled at the bottom of the side walls of the finished product. Bottom ends are coated with wood glue. To clean its excess, need a dry cloth. The components of the box are assembled and strongly pressed against each other. Screws twist into the drilled holes. Before finally screwing screws, you need to check the correct location of all parts of the finished product. To make the tool box easy to use, a handle made from a cylindrical rod is attached to it from above. The core can be made of wood or metal. How to make similar designs for flowers? Repeat the same operations again. And fasten the handles on the sides with the help of screws, so that the flower box is more convenient to use.

Manufacturing of sliding construction

Technical drawing of a wooden box.

It is believed: the sliding structure is more difficult to manufacture than the ordinary one. It really is. Calculations and measurements, when such boxes are made, require more complex. Before you start to make a retractable structure, you need to decide the question of where it will be. If drawers are necessary for the cabinet, it is better to first make one for any other piece of furniture in order to understand the principle of operation and to master the manufacturing technology in practice. For a start, it makes sense to try to restore the old cabinet, making drawers for it. First, the doors are removed from it and the door hinges are unscrewed. The first is measured "working depth". By this term is meant the inner surface of the sidewall, that is, the distance that the drawers move. Each of them has an external part, which is called the facade. There is also a facade at the bedside table. Based on this, and calculated all the facades of the boxes. The height of the facade of the cabinet is divided by their number. From the resulting figure take away the distance of the gaps multiplied by their number.

The selection and calculation of guides is the most crucial stage of work. For a retractable design, it is best to select full roll-out guides. When there is already experience in the manufacture of sliding cabinets, it makes sense to go on roller guides, the installation of which is much more difficult. On the guides for the box does not make sense to save. The better they are, the more functional and reliable the piece of furniture will be.The marking of guides is not as difficult to accomplish as it seems at first glance, the main thing is to be extremely attentive. The calculation of the guides begins at the top. On the right and left parts of the upper pair of guides will not differ. The marking is performed at a height equal to half the height of the upper facade. All the following markings are carried out in accordance with the dimensions of the drawer and the front of the bedside table. As soon as the marking is done, they proceed to the manufacture and assembly of the products themselves.

Fastening of guide elements

Designs of folding boxes and drawers.

The drawers are best made from solid wood or fiberboard. Furniture drawer is required for each drawer. Assembling boxes of fiberboard is almost no different from the assembly of wooden, but it has its own nuances. Before proceeding to the installation of boxes, they glue the edge. For this operation at home do not need complex equipment. With the help of an iron and a dry cloth, the edge is applied to the desired end face and gently heated with an iron. To trim the excess edges, you will need an ordinary kitchen knife. It should not be sharp, so that the laminate of which the edge consists is not affected. If the box is solid wood, there is no need for this operation.

When the boxes are assembled, the guiding elements must be properly strengthened. The guides of full roll-out should be divided into 2 parts. The wide part is fixed to the side of the drawer, narrow - to the side of the box itself. The guides are fixed with a small indent from the side of the cabinet (about 3 mm) and then proceed to the fastening of the facades of the boxes. First of all, they are drilled holes for further fastening handles. Through these same holes attach the facade to the main part of the box.

The first is a rough fixture, as soon as it is completed, you need to check the functioning of the box and only then fix everything completely.

Recommendations for creating a drawer

A dresser drawer assembly scheme.

There are different types of fasteners, however, as experts say, it is best to use confirmatics for drawers. If the drawers are small, they count the number of corners and get the number of required confirmators. For drawers, too, need a pattern. The most difficult stage in their manufacture is the bottom. Since the drawer is retractable, it, unlike the ordinary, is mounted in 2 stages. At first, they do everything on the draft, check that the drawer is installed correctly in the bedside table, and only then fix everything clean.

If the box is made of solid wood, it is better to immediately varnish it after finishing the assembly. When you need drawers for linen, designed for washing, and there is no large sheets of wood for them, then you can make them from thin slats. They are suitable for the manufacture of the frame, bottom and front boxes.

And for the manufacture of sidewalls, you can use plastic mesh, which will provide additional ventilation to things. In some cases, for the manufacture of such boxes are used and metal mesh.

If, however, you need one large non-drawer laundry box, it is made using the same technology as for the tools, only the dimensions are adjusted.

Didn't find the answer in the article? More information on the topic:

-

High-quality furniture from shields with your own hands

Furniture from the boards with their own hands. Preparatory work. Full production of a bed from the first to the last step. The time after which you can begin operation.

-

Installing the ceiling from wooden slats

The ceiling of wooden slats, its features and types. Dimensions and classes of wooden slats. The procedure for installing the ceiling. Tools required to install the ceiling.