Many of their private homeowners are likely to have an idea of using siding as a finishing material, so they should also be aware of a variety of them, such as vertical metal siding. The specified material in its working parameters significantly exceeds similar vinyl products, which gives us every reason to acquaint you in detail with the technique of its installation. Immediately make a reservation that the installation of vertical siding with your own hands - is not an easy task, requiring a certain amount of training from the performer.

Specifications and conditions of use

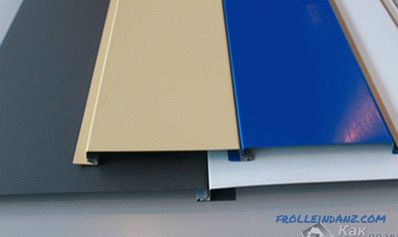

Aluminum vertical siding

Aluminum vertical siding

The type of finish we are considering - these are decorative panels of aluminum or galvanized sheet steel, protected from external influences by a special multi-layer coating of polymers of various colors. As for the vertical construction we are considering, it is represented by special plates having a smooth or structured surface and simulating the flooring with boards.

In addition to the basic blanks, a set of panels includes a number of decorative elements that facilitate their installation and give a neat, finished look to the facade of the building. Vertical siding plates have the following remarkable properties that fully pay back the cost of acquiring them:

- durability (service life is up to 50 years);

- decorative appeal;

- stability to climatic influences while maintaining the brightness of the color palette;

- environmental friendliness, eliminating the possibility of the material emitting harmful substances;

- ease of installation of the panels (due to their special shape, which significantly simplifies the finishing of the building openings).

Before you install siding panels, you will definitely need to think about the placement of insulation material that reduces the thermal conductivity of the outer coating. We note especially that the siding finish will not require you to prepare a perfectly flat surface, since minor irregularities are hidden under a special crate (frame) used to fasten the panels.

Surface preparation, tools, fasteners

Wall cleaning

Wall cleaning

Before arranging the carrier the frame should be cleaned of mud from the walls of the building, and then dismantle all removable parts of the exterior finish, including shutters, trim, drainage elements, etc.

In order to avoid accumulation of condensate under the decorative layer, at the initial stage of preparatory work wall treatment with a moisture resistant primer using antiseptic additives. During the installation process, you will need a standard tool kit, available from any homeowner. These are:

- level (level);

- metal shears;

- construction stapler;

- tape measure, hammer and angle bracket.

To fasten the plates use special fastening elements included in the package.

Preparation of the lathing

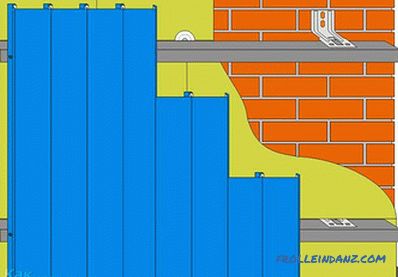

Lathing and insulation

Lathing and insulation

The lathing for siding is made of even and dry wooden timber 50 * 50 mm, fixed on the walls horizontally (in increments of about 40 cm). In some cases, for these purposes, special metal profiles are used, fixed to the walls with the help of metal hangers or brackets. Additional profiles are used to close small openings and for additional elements.

Hard insulation boards made of mineral wool or polystyrene foam, fastened to the walls with plastic dowels or dry construction mixtures, are most often used as insulation.

From above, they are covered with a layer of plastic film used as a vapor barrier. The film is fixed on the plates with the help of a stapler, and the crate itself is mounted over it.

Installation of siding

Installation of vertical metal siding

Installation of vertical metal siding

Installation of vertical siding is done according to the instructions manufacturer, which will require you to preliminary study it.

First, the so-called additional elements are mounted, namely:

- angular and edging profiles or ebb (if there is a base);

- “starting” strips;

- special J-profiles;

- trim (moldings).

In the so-called "central" version of the assembly, first, two starting plates are attached to the center of the facade, from which the entire surface of the coating will be mounted. When corner assembly, starting from the corner, the start plate is fixed in a special profile, since this decorative trim element does not have its own fasteners.

Vertical panels are mounted on the frame with self-tapping screws, which are screwed in sequentially from above, in the center and at the bottom.The place of attachment should be in the center of the timber (profile); at the same time between the cap and the fixed panel should leave a gap of about 1 mm (for thermal expansion).

In order to avoid distortions during the installation of plates after every three elements, you should check the correctness of their installation on the level (see the video). Also, it should not be forgotten that in the places of joining the panels with additional elements there should be a millimeter expansion gap.

Finishing the house with vertical siding

Finishing the house with vertical siding

Video

This video demonstrates the installation of vertical vinyl siding quadrohouse: