One of the important attributes of the bath is the boiler. Modern boilers work on different sources of fuel, which determines not only the quality of work, but also the cost of both the apparatus itself and its maintenance. You can make such a device or, at least, you can install it yourself, thereby saving you a lot. In this article we will talk about how to do it from a pipe (metal), consider installation options, and also provide diagrams, drawings, photos and video instructions.

Types of boilers

Solid fuel boiler

Solid fuel boiler

Depending on the type of fuel used, all The known constructions of boilers (metal furnaces) for baths are currently divided into the following classes:

- gas units;

- electric;

- working on solid fuels;

- pyrolysis;

- working on liquid (diesel) fuel.

The manufacture of a gas boiler, which is the most economical option out of all listed, is possible only if gas has already been supplied to your site.

A feature of such devices is that during operation they almost do not emit any odor or burning and do not require preparation of fuel for the whole year.

The indisputable advantage of electric type devices is the absence of any hazardous waste and the ability to do without ventilation systems. These boilers also take care of the availability of long-term fuel stocks; but with this choice we should not forget about the constant increase in the cost of electricity consumed by them.

Making the boiler

Making the boiler

Solid fuel boilers are capable of supporting both the combustion process and required heating temperature. But, unlike their gas and electric counterparts, they cannot operate continuously and need to regularly load new batches of fuel.

Pyrolysis and liquid fuel boilers are performed, as a rule, according to complex technological schemes and are unlikely to be implemented in normal living conditions. Only the first three of the types of heating structures considered by us are suitable for independent production. We offer to your consideration the most common today version of a solid fuel device that runs on conventional wood.

Construction

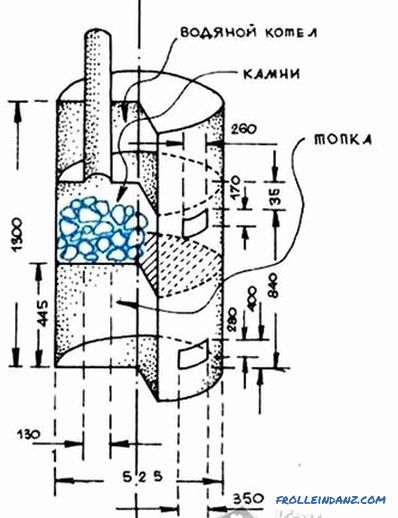

Scheme of the boiler for the bath To begin with, you should stock up with all the necessary equipment and tools for assembling such a boiler. From the tool you will need a welding machine and a “grinder”, and you can use a 200-liter metal barrel (horizontal version) as the initial blank. To equip the boiler of the vertical type, you have to pick up a segment of a thick-walled pipe with a diameter of about 50 cm and a length of about one and a half meters. The device made of such material can warm a room with an area of up to 10 square meters.

Scheme of the boiler for the bath To begin with, you should stock up with all the necessary equipment and tools for assembling such a boiler. From the tool you will need a welding machine and a “grinder”, and you can use a 200-liter metal barrel (horizontal version) as the initial blank. To equip the boiler of the vertical type, you have to pick up a segment of a thick-walled pipe with a diameter of about 50 cm and a length of about one and a half meters. The device made of such material can warm a room with an area of up to 10 square meters.

Consider this option in more detail.

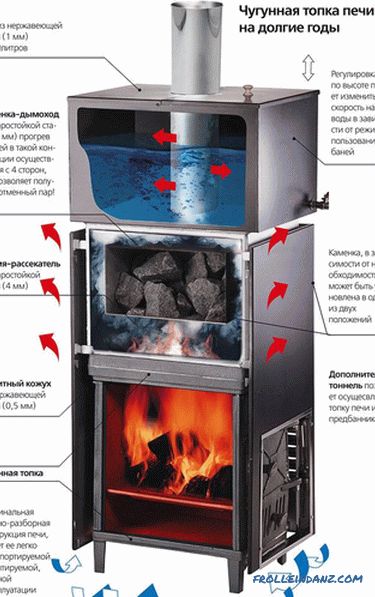

The whole pipe is divided into three parts, each of which is a specific functional unit of the furnace used for its intended purpose. The lowermost and located above it part of the space of the pipe is used under the firebox and stone. They provide the required operation mode of the boiler and create conditions for its normal functioning. As part of the heated billet with water (tank), that part of the pipe billet is used, which is located at the very top (above the stove and stoker).

The lowermost sections of the pipe (blower, firebox and heater) are equipped with partitions, on which special gratings are hung - grate bars, freely sold in specialized casting shops. The heater section is filled with small oval-shaped stones, the structure of which allows you to “keep” warm for a long time.

In a vertical oven, a compartment serving as a hot water tank is installed directly above the heater. To do this, another partition is mounted directly above it, which is the bottom of this compartment.

A special opening should be provided under this chimney pipe, shifted closer to the rear wall of the boiler. From above, this compartment has a partition with an opening for the chimney, which covers only part of the tank. The remaining uncovered part of the partition serves as a hole for pouring water and is supplied with a special cover.

Installation

Protection of walls, ceiling

Protection of walls, ceiling

The installation of the boiler should begin with the preparation of the foundation; at the same time, the power of the latter will depend on whether you plan to brick it or not. You will need such a lining only if you are accustomed to steam in several "visits" and you want the heat to stay in the steam room for as long as possible.

The foundation for the boiler is made of refractory bricks, which are placed on a previously prepared site in two rows and then poured with ready-mixed concrete. The dimensions of the site for the foundation and its removal from the walls of the steam room also depend on whether you are going to make a brick facing.

For safe operation of the metal boiler installed in the steam room, the walls in the area of its location should be covered with a layer of refractory material (Isover, for example). The places of laying the chimney pipe through the wooden elements of the construction of the bath should be protected with a special refractory material (asbestos).

Video

In the following video you will see an example of a stove for a bath with a hot water boiler:

Photos

Scheme of the boiler

Scheme of the boiler

Homemade boiler for the bath

Homemade boiler for the bath

Divide the pipe into three parts

Divide the pipe into three parts